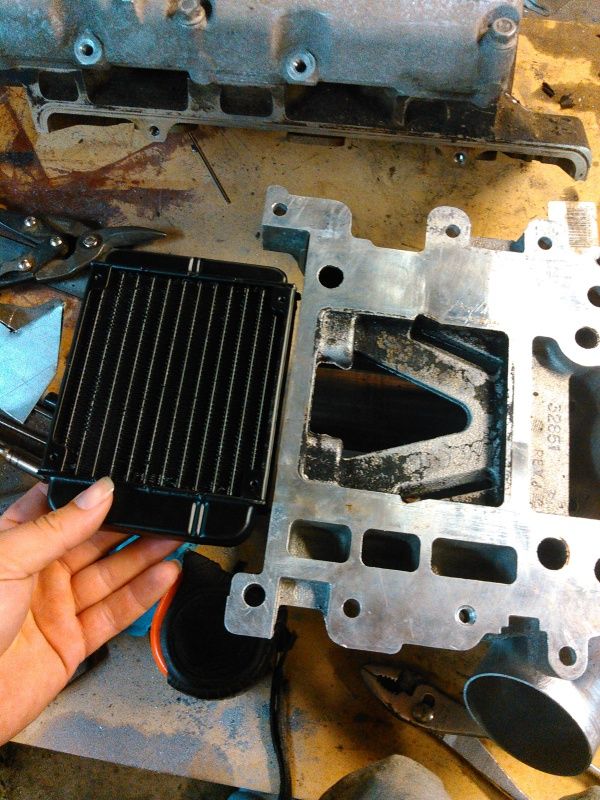

Those inlets are too small-6mm. And it's a 4-pass core, instead of the 2-pass that I thought I was getting.

So, fix the inlets...First thing is to close up the old holes and weld a thick pad of aluminum that I can either drill and tap, or weld a tube onto.

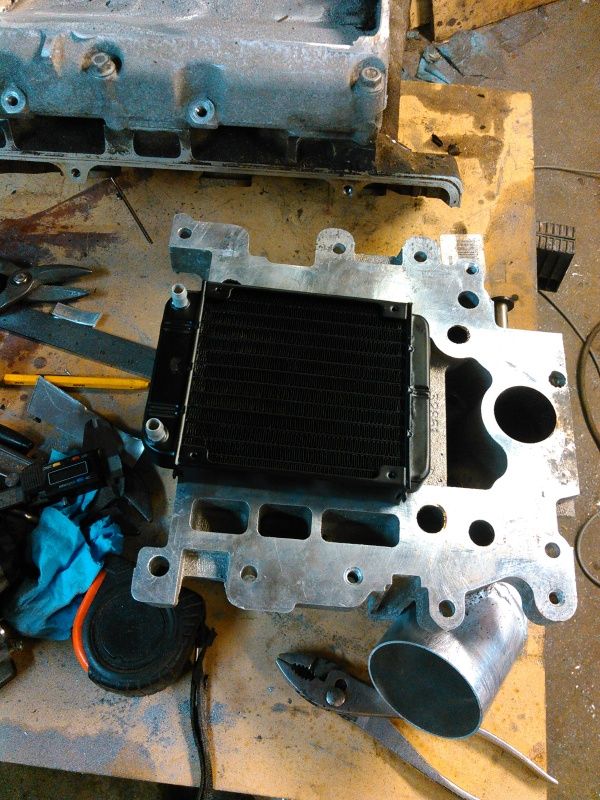

Checking to see how it fits down in the lower half-If I raised it up 5/8" of an inch it will fit absolutely fine. I am pretty sure I know how I'll do this now. Gonna be a lot of drilled and tapped holes...

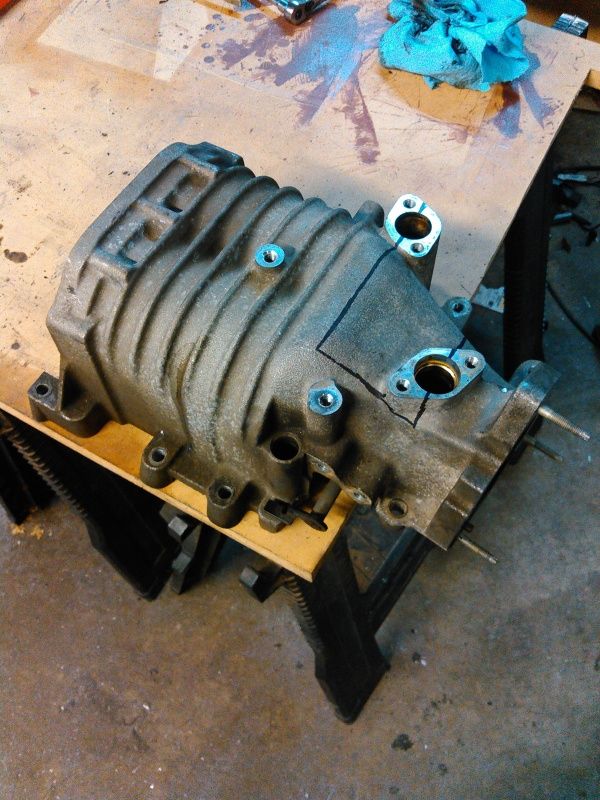

Had to pull the header jig off the temporary work table so I could mock up the belt drive-I can easily get the supercharger into place where the factory nosedrive will line up. I am VERY tempted to just make a pattern and pour a new casting, that will accept the supercharger mounting plate. This will let me use a bolt-on plate and for FWD or transverse mounted engines, and an un-modified supercharger could be used. For longitudinal applications, though, there isn't any room without chopping up the firewall. The supercharger case would have to be modified.

Using the CamaroBird water pump means I may either add an idler pulley before going over the power steering pump, or have to modify the power steering pump bracket to clear the belt.

I did yank that bypass pipe out today. It just isn't going to work for what I need it for and I'm using the CamaroBird bypass in the engine block, all that pipe does is recirculate water to the inlet of the water pump until the engine warms up-basically a thermostatic bypass. Once the engine is up to temperature and the main thermostat starts to open, the bypass pipe gets closed off and forces all the coolant to run through the radiator. This speeds up warmup times and gets the engine into closed-loop faster, which means lower emissions.

I will have to drill and tap for the heater hoses, I think. Does anyone here have handy notes on getting the heater hooked up in an S10 truck? Should just be one hose from the water pump, and one hose from just behind the thermostat, I would think...

Also just realizing that while the camaro accessories will simplify belt routing, they also mean giving up the clutch-driven fan of the S10, because it doesn't line up. That sucks. That engine driven fan just will NOT let the engine overheat, no matter what. I do have a Volvo 960 Turbo 16" 2-speed electric fan, though, so and it moves serious, serious air. It had to, to pull air through the A/C core, intercooler, oil cooler, and radiator on the volvo.

Next on the list of things to fix is the temperature sending unit for the dash gauge. The iron head and aluminum gen2 engines have a port in the corner of the cylinder head, and the computer pulled temperature from the thermostat housing. I am planning to fit the stock 3500 temp sensor in the thermostat housing, and the gauge sending unit will most likely be another stock 2-pin sensor installed into the stock 3500 location. I am under the impression that the transfer curves for the two sensors are identical, GM uses the same sensor for oil temp, water temp, intake air temp, etc. Only difference is the two pin sensor needs one pin grounded to the block for the gauge to work.

Leave a comment: