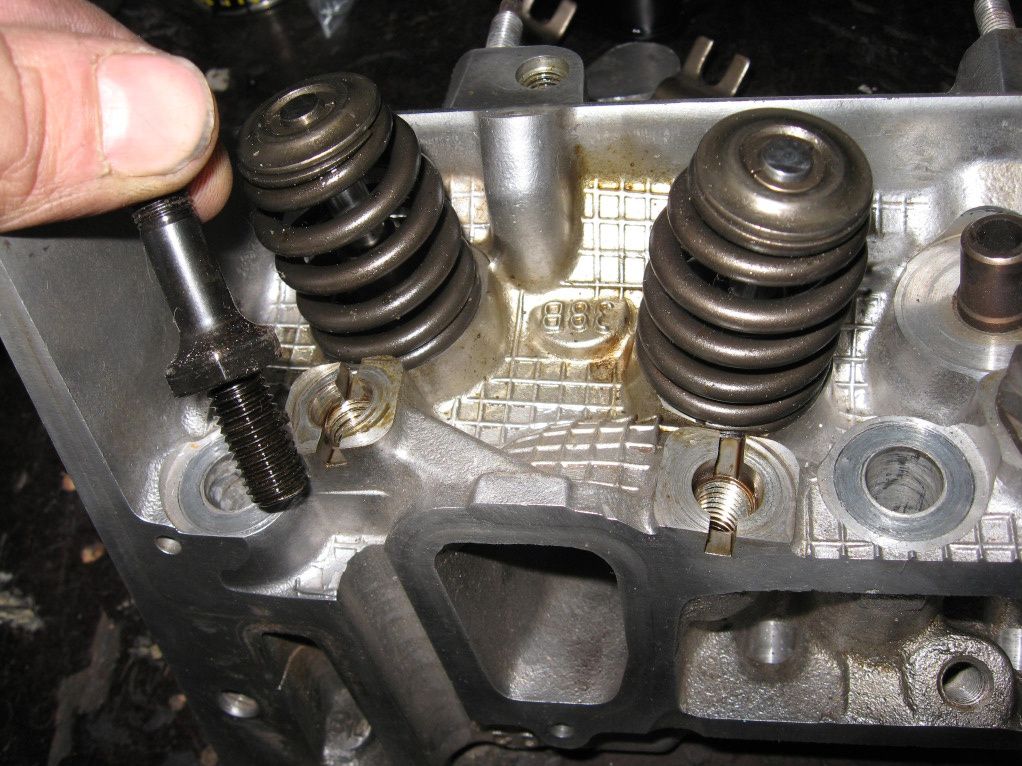

There is a possible oiling issue.

Those lifters are "drop in",but as you know, oil goes thru the push

rods to the rockers.

And the oil holes in those mechanical lifters are in wrong places.

Other side is without oiling and the other side gets too much oil.

The two lifter oil galleries in 3100 block are different places.

Those lifters have to be modified .

Would be easier to buy ones that are planned to that engine.

Announcement

Collapse

No announcement yet.

stud upgrade for factory rockers

Collapse

X

-

Perhaps I'm missing something here, but what is so special about these lifters? Last I checked a 3400 SFI lifter is a standard .842 bore. And many LS and SBC lifters are available in that bore. It should just be a matter of pushrod lengths?

Or is there an other issue I'm not aware of?

Leave a comment:

-

Sorry to answer so late, I did not notice your question.Originally posted by Driver_10 View PostHow did those solid lifters and studs I sold you work out?

So far the mechanical roller lifters that I bought from you, are the only ones , that I have found

to this engine.

Crower is working on a project to get me another set of mechanical lifters.

They have been talking that Buick V6 lifters would be bether.

So far I am putting your Crane lifters to my engine.

Leave a comment:

-

Poor choice of words. The studs will flex more. The stands resist flex better because of their shape and size. Hopefully that makes more sense.

Leave a comment:

-

Since they blot flat down to the head, how could they transmit any flex? They have alot larger surface area than the stud itself. If anything the stud would transmit more since the base is smaller.Originally posted by NateD4 View PostAlso forgot to mention the rocker stands help transmit some of the flex and bending if you have the bolts torqued correctly.

Leave a comment:

-

Also forgot to mention the rocker stands help transmit some of the flex and bending if you have the bolts torqued correctly.

Leave a comment:

-

Any idea what kind of natural frequency you are seeing from that setup?

I contemplated getting rocker studs but I think the removal of additional material around the aluminum could weaken things at least on the Gen 5 heads. Adding a helicoil will probably cut down on the life of the bolt hole a bit.

Also what kind of lift are you running that you need longer springs? I'm setting my 3900 build up for 8500 RPM and am looking at the PAC 1519 springs which are an LS1 Beehive with 360 lbs open force (about 320-330 with the valve lift I'm running). As it is my preliminary analysis shows that I probably wont' need much more than that for 8500 RPM operation.

Leave a comment:

-

How did those solid lifters and studs I sold you work out?Originally posted by veekuusi View Post- stock 3400 = bottom M10 , top M10

- aftermarket roller rockers = bottom M10 , top 3/8

- my project = bottom 7/16 , top 3/8 (ARP)

I am updating my rocker arm studs to longer ones .

Because probably need longer valve springs and therefore longer valves.

Have to drill the hole in the head larger and put a helicoil insert.

I can not do the job in my garage , my friend is doing that job.

That is why no pictures yet.

Most difficult is to drill the new larger hole downright.

There is not much material round the hole.

The helicoil insert makes it stronger , but it can still break down , because the aluminum

fall to pieces.

I understund there is not problem with the studs in normal usage.

But when you have high revving engine with heavy valve spring loads, that is

when this maybe an issue.

I am working on a stud girdle also.

That is not brought to the desired final state yet.

Leave a comment:

-

How would you quantify the stability of the shaft vs spacer rocker mounts as used on Gen V heads?

Leave a comment:

-

Helicoils are great if you have enough material thickness for them. I'm not sure on Gen V heads because I haven't investigated yet. But overall the spacer blocks will be more stable than rocker studs. People shouldn't 'upgrade' to rocker studs if they have spacer blocks. Even replacing bolts is 'gimmicky' as the aluminum is probably the weak point unless you have proper thread length (thread engagement).

Leave a comment:

-

Not true on the as stable as shaft rockers, but they work pretty good. Honestly I have never heard of properly torqued rockers coming out. EVER. On a 660. I have messed up a few and helicoiled them before. No prob. Honestly Helicoil is prob the best. Edelbrock helicoils their race heads before you buy them IIRC.Originally posted by NateD4 View PostWhy do people not think the Gen III, IV, and V rockers aren't stable?

The steel mounting pedestals are fairly stable. Probably as stable as shaft mount rockers.

Leave a comment:

-

Why do people not think the Gen III, IV, and V rockers aren't stable?

The steel mounting pedestals are fairly stable. Probably as stable as shaft mount rockers.

Leave a comment:

-

How about something like a twin shaft. Like these

No need for any girldes, very stable, and possibly easy to make work with a stock rocker....and you can use studs that would not have to be machined down and no guide plates.....Just sayin. Or you can go the old school way that scorpion did with their LS rockers and use a pedestal with flats and have a piece of steel quite like the guide plates hold them together so they do not spin or move. No need for guideplates or extra machining and very stable. And possibly more cost effective.

This is the new pedestal they make for the LS3/L92 style heads, a slight improvement on their older design of a pedestal and a holder plate.

This is roughly what the old pedestal looked like, you can clearly see the flats on them where the U channel sits.

Leave a comment:

-

how about rocker studs that are long enough to make it through the valve cover, then lock nut the studs to the valve cover? :P

Leave a comment:

-

[QUOTE=Superdave;450187]The gen2/early 3100 guideplates would help a little but the majority of the problem is at the top of the stud.

longer studs and something like this is going to be the answer...

Superdave, you might be on to something here becouse the stud gridle in the picture does not use longer studs. The gridle is gripping the top of the adjusters. The rocker stud is normal size but the rocker arm nut/lash adjuster has a extended top for the girdle. Have not looked, maybe someone makes one in a 10 mm size.

Leave a comment:

Leave a comment: