Announcement

Collapse

No announcement yet.

stud upgrade for factory rockers

Collapse

X

-

The splaying of the valve makes it a bit tougher, but I may be able to find someone to make them. How many other people are serious about them?

Leave a comment:

-

find longer headed bolts with a threaded insert on the heads of them, bolt them on, fill the valve cover with clay, remove, trim out clearance and unnessisary weight, make a negetive, cast it, drill holes to run bolts into fancy rocker bolts, and done. the only way to accomplish this is to make the valve cover the gurdleLast edited by bob442; 02-03-2012, 10:13 AM.

Leave a comment:

-

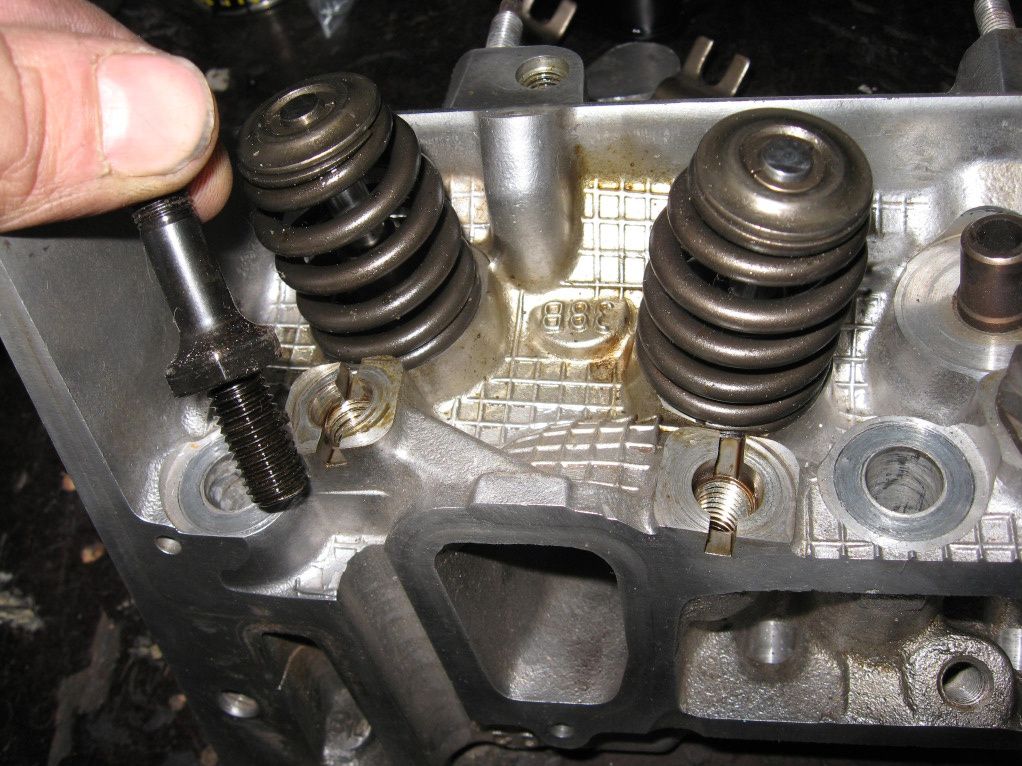

The gen2/early 3100 guideplates would help a little but the majority of the problem is at the top of the stud.

longer studs and something like this is going to be the answer...

Now, to talk Marc into making them, and some valve covers that they'll fit under.. haha

Leave a comment:

-

I think those are simply pushrod guides. Perhaps to help with pushrod bending/vibration at high RPM?

Though something similar might be do-able.

One thing interesting about the Gen III+ heads they have the steel mounting pads for the rockers. LS7s which use similar rockers do not have this, nor do the older style. They rely on the stud to transmit all the bending. If torqued properly the Gen III+ rocker mount pedestals help to transmit some of the bending to the base at the head.

Leave a comment:

-

what about integrating something like the older 3100 heads. if we could get longer studs for the stock rockers it could work.Originally posted by Superdave View PostI've always thought about building a stud girdle but with the limited space it might be a major pain.

Leave a comment:

-

I think the intake clearance is too tight IIRC.Originally posted by bob442 View Postif you intigrated it into the stock valve cover...no it wouldnt

Leave a comment:

-

Hmmm I've often thought that same thing.

Is anyone seriously interested in this? I've been toying with the idea for a while. I could create a 3D CAD model and have it rapid cast into new valve covers. I have no idea exact costs, but if anyone was interested in pursuing it and serious about it I wouldn't mind investing the time to make the CAD models to give to the pattern shop for casting or forging..... (gears are now turning rapidly...)

Leave a comment:

-

I've always thought about building a stud girdle but with the limited space it might be a major pain.

Leave a comment:

-

Well, if/when my 8mm rocker arms fail when spinning the motor to 7000rpm with PAC 1518 springs and a WOT Race cam, I'll let you know.

A few numbers:

At a 1.76" install height, the PAC 1518 spring has a spring pressure of 142.53#.

At maximum intake valve lift of .570", the spring pressure is 321.13#.

At maximum exhaust valve lift of .555", the spring pressure is 318#.

That makes the PAC 1518 a bit stiffer than Superdave's Comp 26915 springs.

So basically I'm in the same boat praying to the 660 gods.Last edited by mfuller; 01-14-2012, 12:07 PM.

Leave a comment:

-

- stock 3400 = bottom M10 , top M10

- aftermarket roller rockers = bottom M10 , top 3/8

- my project = bottom 7/16 , top 3/8 (ARP)

I am updating my rocker arm studs to longer ones .

Because probably need longer valve springs and therefore longer valves.

Have to drill the hole in the head larger and put a helicoil insert.

I can not do the job in my garage , my friend is doing that job.

That is why no pictures yet.

Most difficult is to drill the new larger hole downright.

There is not much material round the hole.

The helicoil insert makes it stronger , but it can still break down , because the aluminum

fall to pieces.

I understund there is not problem with the studs in normal usage.

But when you have high revving engine with heavy valve spring loads, that is

when this maybe an issue.

I am working on a stud girdle also.

That is not brought to the desired final state yet.

Last edited by veekuusi; 01-14-2012, 09:38 AM.

Last edited by veekuusi; 01-14-2012, 09:38 AM.

Leave a comment:

-

Are you having issues with the bolts loosening up or are you just afraid they will at high RPM?

If the former you may have some thread issues in the heads (I'm assuming they are aluminum??). If that is the case there are a few fixes.

In the case of the later (which I am dealing with on my build as well) the issue is concern for seating forces.

On Genn III and later heads (to my knowledge) the rockers contain a square looking, boss that is part of the rocker/bolt assembly. This is intended to help reduce stress on the bolt. It primarily helps with the back and forth bending force applied to the bolt and aids in eliminating some of the tendancy for the bolt holes to elongate under extreme wear.

To my knowledge I have never personally seen or heard of a stock engine with an issue where the bolt hole was elongated or pulled out (anyone else have any input on that?).

The 'easiest' way to assure the rockers you have will run to higher RPM without bolt failure is to carefully examine the following options:

1) Drill the thread longer (may be tough, or weaken the head depending on where and how you drill).

2) Use the GM square pedistals or similar when possible (making their base larger may help depending on whether there is room or a spot face on the head that accomodates larger than stock).

3) Consider using a threaded insert. This option increases the shear stress area and thus available force on the bolt. However you could weaken the surrounding metal.

The last more expensive option (assuming you area already running aftermarket rockers) is to make a girdle for them... not sure how easy or good this will be... but I'm looking into it for my build....

Anyone else have any additional comments?

Leave a comment:

Leave a comment: