this is all anyone knows for now.

Announcement

Collapse

No announcement yet.

3500 crank

Collapse

X

-

oh, and has there been any details on specific model/year that said billet/steel and or forged/steel crank comes in, or is more likely to appear in? last i knew there was no definitive answer.

thanks

cody

Leave a comment:

-

and the 100cc difference is the bore then if the stroke is the same?

thanks

Leave a comment:

-

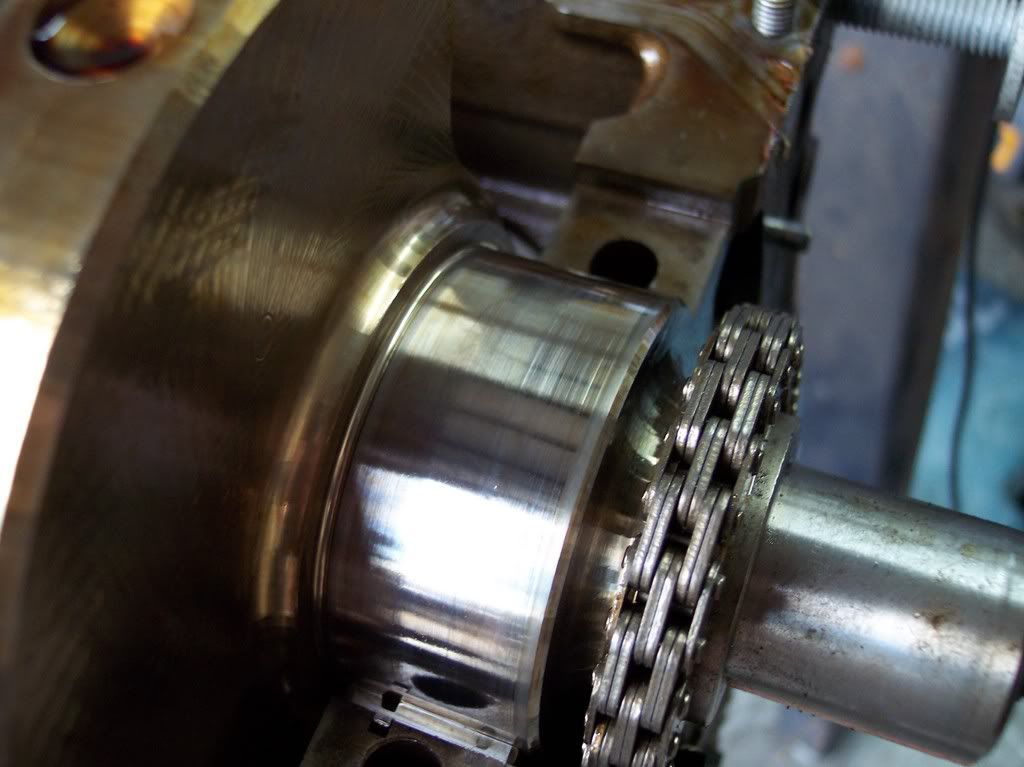

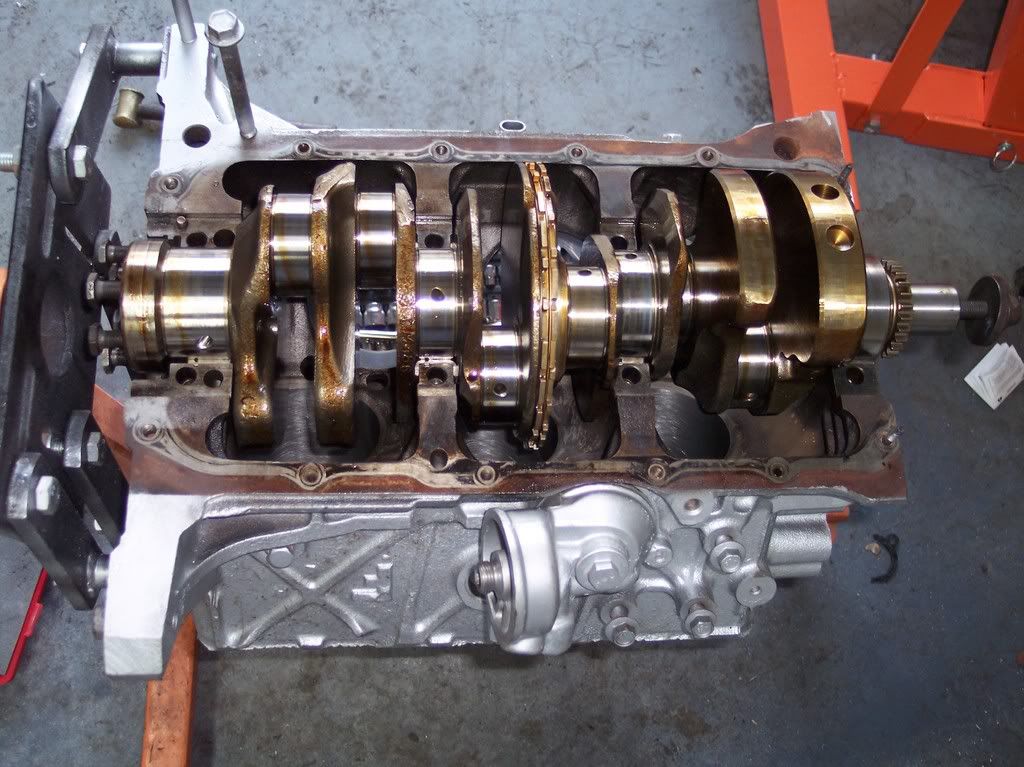

No, the crank has the same throw, but the rod journals were increased from 1.999" to 2.499". People have been discussing offset grinding them to use the smaller journal rods and making a .25" stroker.Originally posted by rsisbetter View PostSO, basically, from what i've gathered is:

1. a 3500 is essentially a punched out 3400, with better flowing top end?

2. The best way to gain cubes is with a 3500 crank in a 3400, (since the 3500 is like a punched out 3400 from the factory?)

Cody

No confirmation yet, but it appears to be billet at the least...Originally posted by 34blazer View Posti cant remember, but has anyone confimed if the steel 3500 crank is forged or not?

I test fit the crank in a RWD 3.4 and it rotates freely. I did not press a piston off a 3500 rod to be 100% sure, but bolted the rod on with the piston sticking out of the block on the oil pan side, and it looks like it would almost make it - of course I could not get a full rotation this way, but gave an idea...Originally posted by montess408 View Postdoes any body know if this stroker crank would fit in a gen 2 block and what displacement i would end up with after a .030 overbore ?? and would i need to get diffrent rods or would the onefrom my 3.1 be good ? and what about pistons i was gonna get a set from a camaro can i still get them ?

Last edited by ForcedFirebird; 12-27-2007, 09:25 AM.

Last edited by ForcedFirebird; 12-27-2007, 09:25 AM.

Leave a comment:

-

SO, basically, from what i've gathered is:

1. a 3500 is essentially a punched out 3400, with better flowing top end?

2. The best way to gain cubes is with a 3500 crank in a 3400, (since the 3500 is like a punched out 3400 from the factory?)

Cody

Leave a comment:

-

does any body know if this stroker crank would fit in a gen 2 block and what displacement i would end up with after a .030 overbore ?? and would i need to get diffrent rods or would the onefrom my 3.1 be good ? and what about pistons i was gonna get a set from a camaro can i still get them ?

Leave a comment:

-

i cant remember, but has anyone confimed if the steel 3500 crank is forged or not?

Leave a comment:

-

im wondering the same. im deciding on using the 3500 crank with 3400 heads.

Leave a comment:

-

Originally posted by El_Diablo View Postwow... so really that makes a boosted setup almost perfect now because i can use the .250 offset grind, a small journal sbc rod at 5.7 inches (yes, i know they need to be modified) and all that i would really have to get custom made are a set of forged pistons which would allow me to knock the compression even lower (if i even wanted to) and move the ring land down a bit for huge boost

Are you planning on using the 3500 block or 3400 block? I mean this helps me out but i'm wondering what kind of compression i will get with the 3400 block SBC rods at 5.7, and the offset grind before i send the crank off to be machined? Any help, anybody?

Leave a comment:

-

the engine just wants fuel and air, it doesn't car who or whats controling it as long as its within its parameters, give it enough fuel and air and it'll run on anything, the pcm is the picky one... you have to satisfy all of its sensors or it'll f' you over every time

Leave a comment:

-

I am just making it as easy as possible and if I can keep my harness and PCM .............thats pretty easy......................Originally posted by El_Diablo View Postany pcm should be able to control it as long as you have a way to change the fuel and spark trim

i think i just figured out the bottom end of my build

Leave a comment:

-

any pcm should be able to control it as long as you have a way to change the fuel and spark trim

i think i just figured out the bottom end of my build

Leave a comment:

-

Using the 3500 crank, you will need the external trigger sold by the 60V6 store. Theoretically (ok, Joseph has actually done it), you could just fab a new 7x trigger to replace the 52x trigger wheel currently on the crank, then shim the sensor out. The 3400 PCM shoul be able to control it no problem then.

Leave a comment:

-

Considering this is the way to go for boost, how would the electronics play in with the 3400 out and the 3500 in as far as PCM and crank trigger....has anyone looked into that?

Leave a comment:

-

wow... so really that makes a boosted setup almost perfect now because i can use the .250 offset grind, a small journal sbc rod at 5.7 inches (yes, i know they need to be modified) and all that i would really have to get custom made are a set of forged pistons which would allow me to knock the compression even lower (if i even wanted to) and move the ring land down a bit for huge boost

Leave a comment:

Leave a comment: