Originally posted by IsaacHayes

View Post

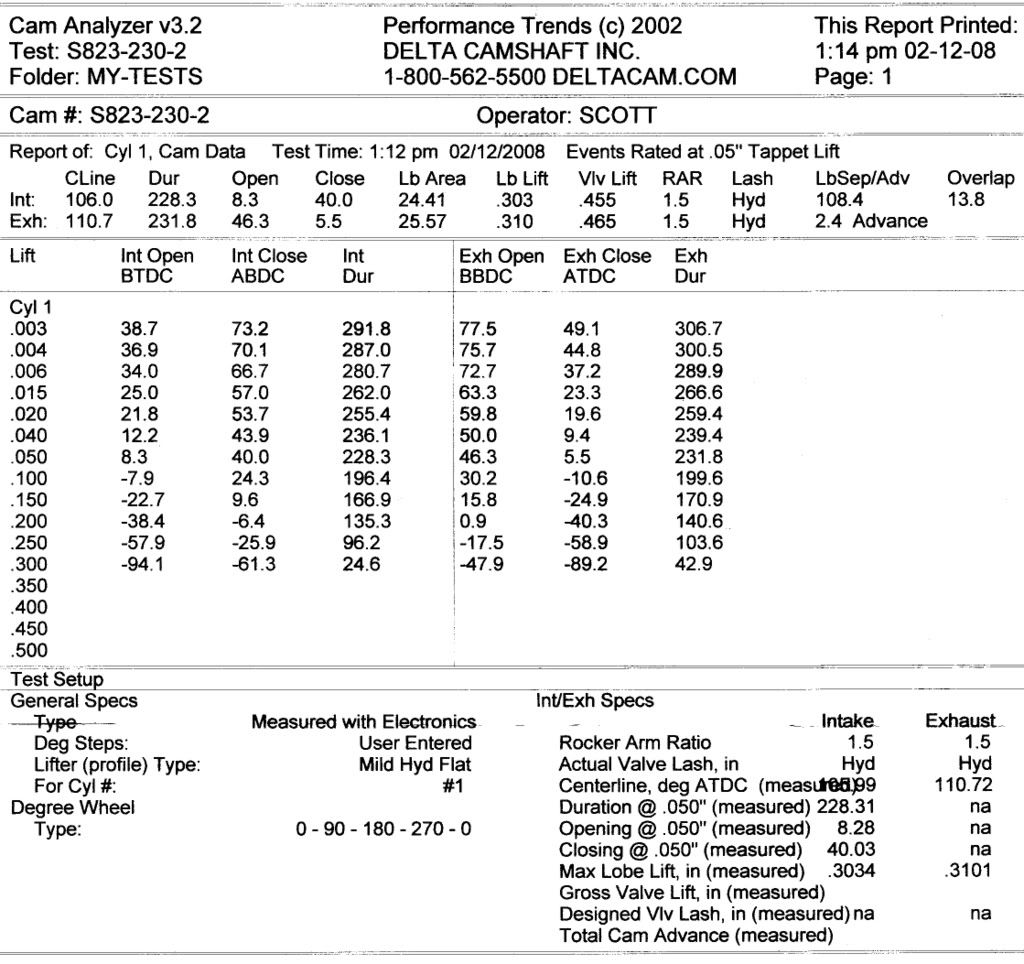

No, I already have the cam...

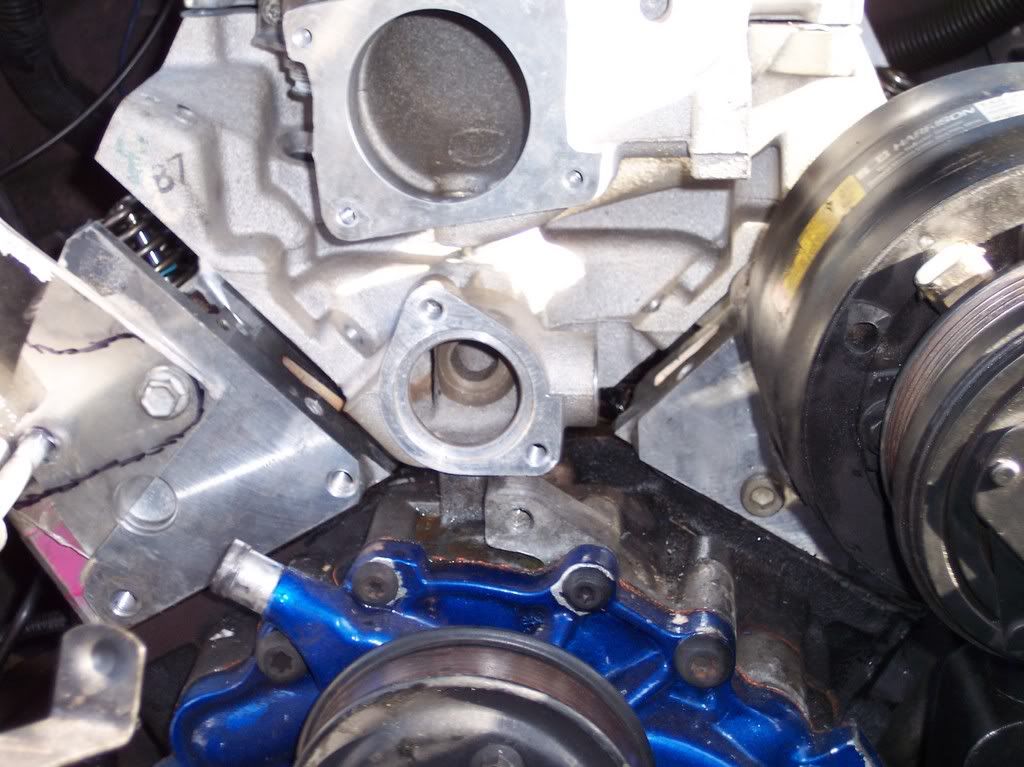

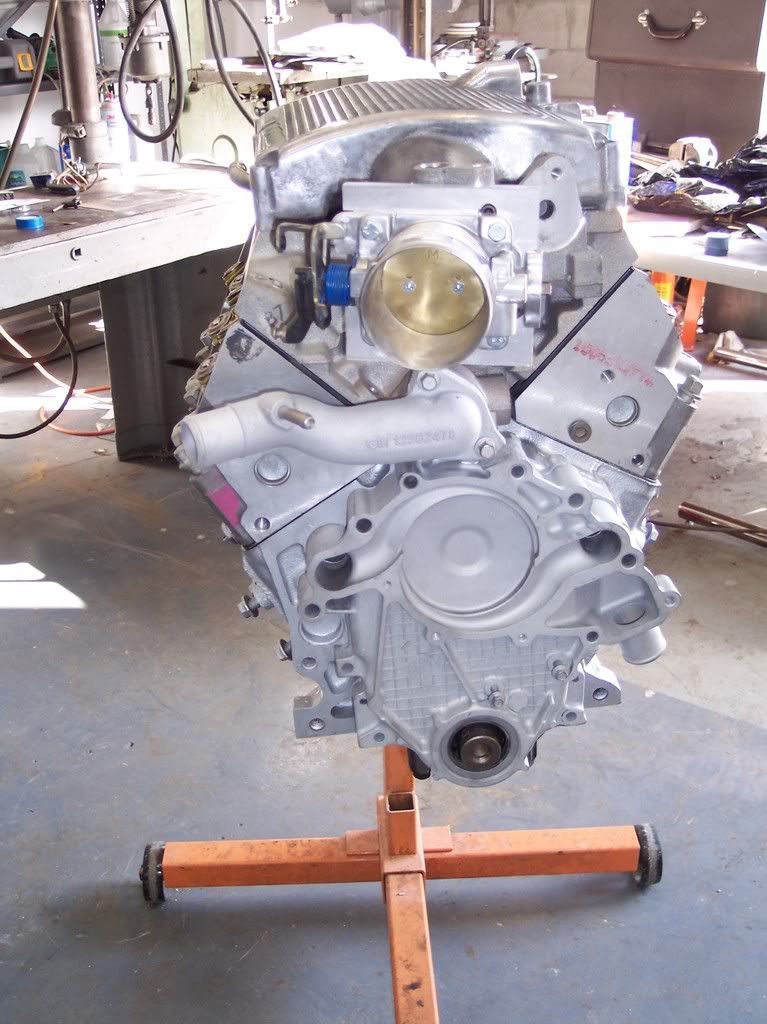

I actually might try a little boost with it as well before I pull the motor to swap to 3400 pistons.

I know two people now with low 11's for compression and are running on pump gas. One has 10psi on his Mustang (iron heads), and the other is running 4psi in a 280zx (aluminum head).

Leave a comment: