Originally posted by betterthanyou

View Post

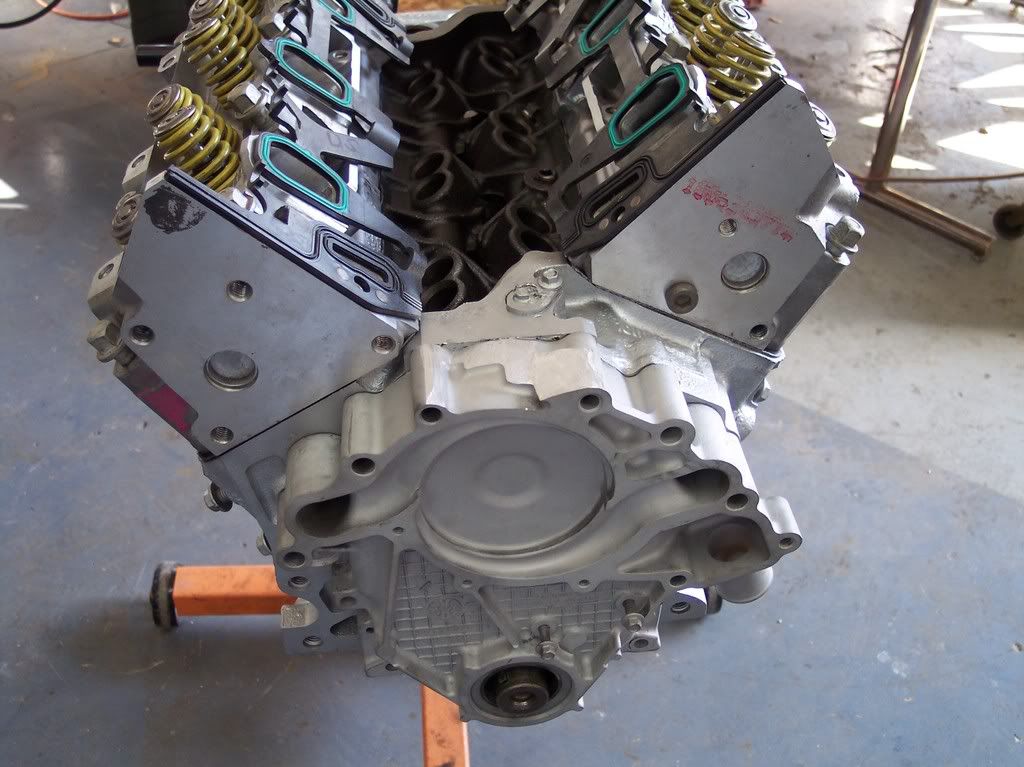

This means the coolant is going to stay in the front of the block in a RWD configuration, correct? It's not going to circulate properly.

Leave a comment: