I think I need to chime in again. Story time:

When I first got into 60 degree V6s back in 1998 I was young and looking to put the baddest a$$ V6 I could dream up in my Fiero. Back then the goal was a 3.2L 14.5:1 compression engine making 400-450 HP. Many people on the forums of the day said just turbo it quit wasting your time and money. Ironically I think they were right. There's a certain achievement and cool factor in having something totally unique and thought impossible...

A lot has changed since then. Mainly the Gen 5 V6s (High Value V6). In my opinion it is a game changer. New heads, new intakes, new tech every where. Better everything.

In the mean time I've come to realize that in order to optimize an engine to the level that it sounds like we are talking here the task is monumental and certainly in my book not worth the time and engineering required.

Now I'm not saying its wrong. However, I am saying that unless you are ready to buy or write your own analysis software, buy a few thousand dollar CAD package, pay to have your parts CAT scanned in 3D to get the production 3D models (which to my knowledge are nearly impossible to get from GM), invest in $50,000 to $100,000 analysis software (CFD, FEA, Dynamics, Combustion analysis etc..) you are chasing details for the sake of chasing details.

I could probably tie up a supercomputer for a few days running a totally correct engine model that would require 2 years to construct. I could also spend a $200K to construct the engine (take a look at J Leno's Pratt and Miller billet blocked 700 HP LS engine for an idea).

There's an old adage 10% of the effort and cash gets you 90% of the way there. The last 10% of the way takes the other 90% of the cash.

[This is why 2-4 years ago one of the F1 teams spent 200 million euros to raise the redline on an engine from around 19K to 20K RPM. F1's rule body decided this was ridiculous. A season or two later the Kinetic Energy Recovery System (KERS) system was devised. Which basically is a hybrid like power boost. They figured if teams were going to spend that much money to raise redlines (which included new materials and crazy coatings), why not spend the time, talent and effort to address problems the rest of the industry could learn from.... ]

Now in my opinion (and for my project) simpler is better to a point. I'm now planning on spending a bit of time to CFD model the ports to see exactly what they are doing before I start porting. BUT keep in mind that even in wind tunnels the time you spend to do something as simple as reduce the drag (or in our case increase CFM) by a few percent is huge. On top of that it can be totally hit or miss. This is exactly why guys like WOT spend the time with the flow bench.

If you want to optimize your exhaust build a few sets and take them to the dyno. Go with a few theories and test them.

If you really want to mess with them you might try CFD (OpenFOAM is free but a bear to use... and you'll want an 8 core computer with 18 to 32 gig of RAM and a few hundred Gig of drive space). But even CFD has its limits... garbage in garbage out. If you pick the wrong equations sets or assumptions, pick the wrong initial conditions or the wrong air properties your small percentage gains mean essentially nothing.

Sorry to get off on a tangent but I think its important to keep things in perspective with your goal. If you want to prove everyone else wrong and show how cool an engine you can build have at it.

Another thing to keep in mind is that Engineering supports the build and as such the build drives the need for engineering not the other way around. Engineering to engineer is fine if you have the resources. But in all reality if you had them you would probably buy something out of the box. Unless of course you like the challenge.

As for my approach. It has changed a lot in 10 years. I've since went from NA only to Turbo and have decided to start with the latest and greatest tech GM had in pushrod V6 (which is also based on another decision process).

My current build will be somewhat of a mix between optimization and forcing more air and fuel into it. But I'm approaching it fully aware of what's in store and accepting that I'll probably spend a bit more then I need to. But I've always wanted to do a build like this we'll see where it ends up.

Just my ¢50 worth.

Announcement

Collapse

No announcement yet.

Exhaust Collector Discussion

Collapse

X

-

What's wrong with using filler material on welds?

BTW some of those tig welds look really good. A few of them look over heated a bit.

Also for anyone that doesn't know you can remove the nitriding from the stainless HEZ by wire brushing it immediately after the purge gas is shut off.

Leave a comment:

-

Originally posted by slw240sx View Postlooking good overall ! i like that runner on the header that first one that i make super short. I like the way you figured out how to lengthen it. that cast stuff i have to give you props, i normally wont even touch the stuff.

http://i158.photobucket.com/albums/t...lscar001-6.jpg

on this, is this stainless steel? can i offer some pointers? over all the weld is nice and straight and consistent, but i spot a major issue. one i really really suffered with for the longest time until someone helped me out. Gas coverage! what are you using on your torch cup wise? are you using a gas lense what size cup? how much post flow, how many CFM of flow on your regulator for SS?

I use all kinds of cups, tungsten and CFM values pending wall thickness, material and rod size. You can be concerned all you want, but that's fuse welded, no filler.

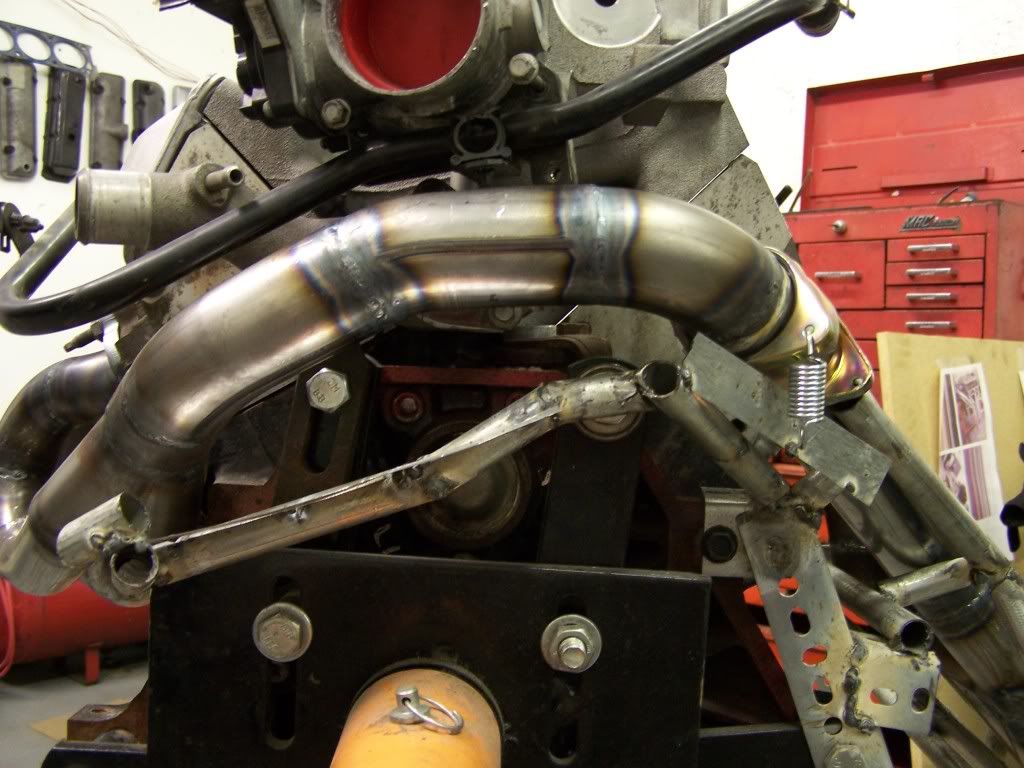

The collectors I posted earlier are 304 SS, 16ga, and are going on these "useless N/A headers" I've been picking away at for almost a year for my e30...

Leave a comment:

-

looking good overall ! i like that runner on the header that first one that i make super short. I like the way you figured out how to lengthen it. that cast stuff i have to give you props, i normally wont even touch the stuff.

http://i158.photobucket.com/albums/t...lscar001-6.jpg

on this, is this stainless steel? can i offer some pointers? over all the weld is nice and straight and consistent, but i spot a major issue. one i really really suffered with for the longest time until someone helped me out. Gas coverage! what are you using on your torch cup wise? are you using a gas lense what size cup? how much post flow, how many CFM of flow on your regulator for SS?

Leave a comment:

-

You saw the prototypes...

How about some cast iron to 14ga tubing...

Cast iron to cast iron...

Leave a comment:

-

that work is kind of rough for a high dollar race team...

that much money invested and i would remade that and focused on getting rid of those cheater cuts and pie cuts. i like the gradual bend on the main tube, but it completely screws it up going with that sloppy angled "cheater cut" then pie cut. that kinda follows my idea that it does not have to be perfect to make power. that charge piping would never fly with me especially if it was a high dollar build like that. i would have done it over or made whom ever built it do it over. how ever that thing made what 1600 almost 1700whp and goes over 200mph? sloppy work but great results.

notice the thin wall collector! now that is a much better collector then i use in production. i bet that is burns 321 stainless. looks to be double slip fit and not welded too. id love to get a look at the hot parts on that thing.

Leave a comment:

-

forced firebird, i just had a nice long post i wrote out to address yours and i lost it in timing out, i dont even feel like rewriting it.

cliff notes.

I have nothing to compare my work against yours, i am not saying i am better. I have not seen any of your recent work. the only thing i have seen are headers you built a few years ago, and those were mig welded. I would like to see your current work and im not saying that sarcasticly, i enjoy showing off my work and looking at other fabricators work. Giving and getting criticism its a great way to learn and expand our skill set.

i know thin wall is not the best, but it holds up fairly well i have kits that are 4-5 years old still on the road.

i prefer the thick wall 304-316 Stainless materials , but in certain builds its not feasible due to cost and weight. thats where 316-321 thin wall with double slip fit connectors comes into play, but again how many grand am people want to pay for a system whos materials will run from 800-1200K in cost alone? none...

the stuff i pie cut build is due to space constraints and customer request. that miata was because the customer wanted it, the LSX powered FD was because space was completely limited and the customer wanted pie cuts and wanted his muffler to be reused which i also had to shorten to get it to fit with that turbo back there. it was not my first choice on the solution. How ever that car did make over 700whp on moderate boost. i know its not the best way, but its what works and what the customer requests.

I know i am not competing in the same market. hell my market is not even GM stuff. my market is Honda, Nissan, Toyota, and Mitsu. i only build this thin wall stuff for milzy. Most everything i build for the other markets is 304 Thick wall Stainless manifolds. I can produce quality on the same level as those you mentioned, i just never dove into the BMW market.

Ill show you pictures of the next manifold i am doing as soon as the customer approves the building of it. its going on a GT3076R powered Sr20det, and i will be making it to utilize the twinscroll housing we ordered for the turbo.

i guess i ended up writing most of it out lol

Leave a comment:

-

You are quite a character, knowledge just flows off your tongue. Just an FYI, the 60v6 is in the New Camaro lol, yes it has room for groceries.Originally posted by HOYSCavi...grocery getter.

People make drag cars out of MG engines too...

Leave a comment:

-

Jon, don't take this as an attack. I'm not going against experience here, but honestly, production and business are usually always about cost vs time. A backyard mechanic has more time to produce one off parts for his own car than a speed shop- looking at every fine detail isn't going to hurt them unless they are looking at a time table to have the car done by. I work in an RV production facility (and I know that probably discredits me a bit in some peoples minds, but some on here know me a bit more and know not to discredit me ) and I know all about cost vs time. I work on piece rate. No matter how long it takes me to produce a unit, I get the same pay, so at work, we run like the wind. This works to my advantage there because it nets me roughly $28/hr on an average week, and I'm out of there by lunch time. But if you think I'm going to put that kind of mentality into my own car, you are dead wrong. I tend to think along TGP37's lines a lot of the time, but I will admit, he dives a bit deeper than I do into the thought process behind it. I also believe he's got more smarts than I do to back it up. Then you have people like John and Ben. I know both of them, and they are going where most don't venture and are trying to combine both worlds to give the customer the best product at a competitive price.

) and I know all about cost vs time. I work on piece rate. No matter how long it takes me to produce a unit, I get the same pay, so at work, we run like the wind. This works to my advantage there because it nets me roughly $28/hr on an average week, and I'm out of there by lunch time. But if you think I'm going to put that kind of mentality into my own car, you are dead wrong. I tend to think along TGP37's lines a lot of the time, but I will admit, he dives a bit deeper than I do into the thought process behind it. I also believe he's got more smarts than I do to back it up. Then you have people like John and Ben. I know both of them, and they are going where most don't venture and are trying to combine both worlds to give the customer the best product at a competitive price.

Leave a comment:

-

Originally posted by HOYS View PostComing from Jon who has designed, built, tested, and mass produced turbo kits that were regarded as some of the best out there for some cars...he is worth a listen.

He is not saying you shouldn't make collectors...but your time, effort, and money could be used for something else more productive. If this was high dollar racing where every single HP was worth the time to get it, you would have no problems. This is a forum about an engine that came in mini-vans, grocery getters, and that's about it.

Viper forums? You make those collectors all day.

FOR RELEASE: 2005-04-12

CONTACTS

Matt Hartford Looking To Set High Standard With GM High Feature V6 Engine

Pro RWD Chevy Cavalier

LAS VEGAS, April 12, 2005 - Matt Hartford arrived in West Palm Beach for the NHRA Southeast Sport Compact Nationals on April 2 looking to establish a solid foundation in his quest for the 2005 Pro RWD title. Over the winter, crew chief Mylon Keasler focused on improving the performance and reliability of the twin-turbo, GM High Feature V6 engine. Now Hartford's Chevy Cavalier appears to be on pace for a run at this year's Summit Racing Equipment Sport Compact championship. During the third and final round of qualifying for the Southeast Nationals, Hartford posted a career-best e.t. and speed stopping the clocks with an astounding 6.554 second run at 212.71 mph. That provided the 33-year-old Phoenix resident with his first NHRA top qualifying spot of the season and a solid beachhead heading into this weekend's SummitRacing.com Nationals at Las Vegas Motor Speedway. The question now becomes, just how quick and fast can Hartford's Chevrolet go?

This is Hartford's fourth year in the NHRA Sport Compact series. In 2002 he won the series championship in the former Modified category after winning national events at Woodburn (Ore.), Sonoma (Calif.), and Englishtown (N.J.), collecting a runner-up at Pomona (Calif.) and earning low qualifying honors twice. Hartford entered the Pro RWD category in 2003, and competed with a four-cylinder engine in a predominately six-cylinder class. He captured a victory at Sonoma and posted a runner-up at Atco (N.J.) for a sixth-place points finish. The move in 2004 to the new GM High Feature V6 began paying dividends in the late summer when Hartford defeated Abel Ibarra in the finals at Dallas, and with Stephan Papadakis, Hartford was part of the first sub-6.60-second Pro RWD side-by-side pass at Englishtown.

The performance of the Summit Racing Chevrolet and the GM High Feature V6 during the last year has improved significantly. "There are parallels with what we're doing with the GM High-Feature V6 and what was done 50 years ago when guys were trying to race the small-block Chevy. Today you can put together a small-block Chevy that will produce a thousand horsepower and run for 100,000 miles. But back in 1955, and the first couple of years that it came out, it wasn't that way because the knowledge level wasn't there yet, the parts availability wasn't there and there was still work to find its full potential. With the GM High-Feature V6, it's only been three years since it was just a design on a sheet of paper. Obviously, we're stressing this engine considerably more than the GM engineers who built the production model ever thought possible. We're making over 1700 horsepower with 202 cubic inches and we're using so many factory parts that unfortunately we've pushed them beyond their limits. When we do, the GM engineers either make us a better part or we go to an aftermarket part, and this all takes time. It takes trial and error, and the only way to find the next weak link is to stress the engine even more. Now we're running consistent 6.50s at about any track we go to regardless of the surface condition. We ran 6.50s at Phoenix and we ran 6.50s at Moroso. We feel we have abundant, consistent power and now we're looking to improve reliability, and that's what we'll be working on this year."

GM Powertrain and their involvement in making the High-Feature V6 the state-of-the-art engine in Pro RWD. "We're on the phone with GM no less than three hours a day, seven days a week. It is an ongoing conversation about what we're working on, what they're working on and how we can best apply what we've learned. Brent Ingraham from GM is at every race for on-site assistance. Their involvement and commitment has been tremendous and will go a long way toward making the GM High Feature V6 a great race engine."

The way the Summit Racing Chevrolet has run at the first two races must have you very excited about the rest of the season. "We certainly feel we have one of the most competitive teams in Pro RWD just from the standpoint that we know we can make horsepower. We also don't mind working 23 hours a day if that's what it takes to be successful. We don't have any qualms about staying up all night working on our stuff, and if we need to do an engine change between rounds, or at midnight following a final Saturday qualifying session like we did at West Palm, then that's what we do. I guess we don't know any better. We don't know that at seven o'clock or eight o'clock you're supposed to pack up and go have dinner, that's not the way we think. We can back our car down to run 6.70s and not hurt parts, but we're not going to the track to run 6.70s. We're either going to win the race, learn something in the process or both. We learned something in West Palm Beach. We had a failure, we know what it was and we're confident it won't happen again. Our car was on a solid 6.50 pass when we had an issue in the first round of eliminations. It's discouraging, it is heartbreaking, but we learned something from it. It also showed everybody else that along with the horsepower, we know how to adapt and that will serve us well throughout the season."

How long have you been with Total Seal? "About seven and a half years. Total Seal supplies about 95 percent of the high-end race programs including 41 of the 43 Nextel Cup Cars, almost all of the NHRA Pro Stock teams run our product, all of the IRL teams and a lot of F1 teams. I have a nuclear engineering degree of all things, but my position at Total Seal is to handle all of the new product development and serve as the contact person for all of the professional race teams. My job is to work with the racers and supply them with what they need. I spend a week in Charlotte about once a month. I love my job so much that I wouldn't give it up even to go racing. The nice thing is that if I have a question about gear ratios, or this or that, or something in the engine, I have an unlimited amount of phone numbers I can call at nine o'clock at night. We may not have all the answers, but we know people who do and that really helps us. There are very few people out there who have the encyclopedia of knowledge that it takes to be successful, and it helps to have resources that you can pull from."

Any special prep for the SummitRacing.com Nationals? "It doesn't matter if we go to 4-11 Dragway in Tennessee on a Wednesday night, and the only people there besides us are the ambulance driver and the starter, or if we're at Las Vegas Motor Speedway in front of 30,000 people. We focus on racing the same way, as hard as we can, pass after pass. When you try and change your approach you fail to focus on the right stuff. Don't get me wrong, we want to win the SummitRacing.com Nationals and set the world record, but we try to run as fast as we can, and win wherever we race regardless of the venue or how many people are watching. We want to do as well when we test as when we go to Las Vegas. We're learning what our car likes repetitively, and once you figure out what works, you have to do things the same every time. However, there will be some opportunities racing on a track as meticulously prepared as Las Vegas Motor Speedway. We were the first car into the 6.60s, we were the first car into the 6.50s. We want the Summit Racing Chevrolet to be the first car into the 6.40s. We're learning every minute of the day. Thank God we have great sponsors like Summit Racing Equipment, MTX Audio, GM, because if it weren't for them we couldn't do this."

What kind of performance potential do you see coming from the Summit Racing Chevrolet this year? "We want to have a car that is capable of running 6.40s. If we can run a 6.50 at Phoenix and Moroso, we know we can run a 6.50 anywhere. Our opponents know that if we get off the starting line we're probably going to put a 'fifty' on the board so your stuff better be tuned-up and ready to go. Our goal is to win the NHRA Pro RWD championship for Summit Racing and GM and to have that No. 1 on our car at the end of the year. With this new GM High-Feature V6 program, it was nice to have the whole winter to work on it and focus on some things that we didn't have time for last year."

Do you think a Pro RWD category with twin turbo V6 engines could fit somewhere in the POWERade series? "Someday, I'd like to see the Pro RWD class race at about 10 or 12 races a year like the AMS Pro Mod Series, and maybe compete here and there at some match races as well."

What are your long-term goals beyond 2005? "My goals have been pretty simple from the first day I saw Lee Shepherd go down the track. I want to win an NHRA Pro Stock championship, plain and simple, but right now I'm going to do what my budget allows me to do. Our focus right now, is winning a championship in Pro RWD."

What has Mylon Keasler meant to your program? "I've known Mylon for a long, long time and I probably wouldn't go racing without him. Mylon and I, we just click and we have that bond where I trust him completely. When I'm in the car, whatever he tells me on that radio, I don't argue. We'll have some discussions on the phone, or when we're at the track on what to do with the clutch, or something like that, but ultimately, there's never been a time in the last six years, there's never been a harsh word between us and there won't be in the next six years. We have a great deal of respect for each other, and even though he's not related to me, Mylon is part of my family. We keep our race shop in Maryville, Tenn., which is right by the Knoxville Airport. For the last five years that's where I've had all my stuff with the exception of the year I was with John (Lingenfelter). It works best for us to have everything in Tennessee and Mylon's shop is dedicated entirely to our program."

Leave a comment:

-

You don't even know your 60V6 history.Originally posted by HOYS View PostThis is a forum about an engine that came in mini-vans, grocery getters, and that's about it.

Leave a comment:

-

Originally posted by slw240sx View Postin my years of experience people who are this way are more likely to abandon a project before its ever even road worthy.

Also if i may, for being a leading figure in this community you awfully hostile to people who are engaged in a friendly discussion. I know we are on different sides of the discussion, but if you are going to involve yourself at least take the hostility down a few notches and try to at least engage me into being open minded. I think you have the wrong idea of my intentions or demeanor. I know i am a total asshole and i am stubborn, but i am also very reasonable and do try to be respectful. dislike my posts with me dumbing down and what not i get that, but be respectful and try to be constructive. That is what makes me not like your posts. they are more often then not attempts at cheap zings rather then a good counter point. Your partner joined in the convo and i actually expected hostility from him as well, but he was welcoming and brought up a good point.

Actually it's because your first post was decent, and while yes you are being civil, which I much appreciate, you are telling members of this community wrong information. Sure, you can use OBX turbo headers or make them from thin steel and make good power, but they won't hold a candle to anything we build. Are we on different sides of the coin? yes. Our customers buy from us because they know they will get the best and we experiment on a daily basis to make sure we test part fitment, put a fair price tag on it, and we are lightning fast with customer service.

We don't build pie cut systems, you mentioned we are wasting our time "doing math" and "overbuilding collectors" when in reality, how much more time is wasted welding little pcs of pipe together when we are making/designing proper systems and installing them properly.

You guys may think we are your competitors, when in reality our current competitors we are after are Metric Mechanic, 666fab and revshift as far as turbo manifolds and fabrication go.

We are starting to shy away from the young crowd that's "boosted to 25psi, yo, t28 turbo FTMFW" and dealing with clients that are building a whole package. If you think we are talking trash, go to the news stand and buy Oct issue of Grassroots Motorsports Magazine, open up to page 68 and look at our smiling faces.

Before you attack Ben about ho many turbo kits he built, I don't think it's any. Does that matter? No. That's not what he does. Let's ask your secretary, your parts delivery guy, your shipper, your head porter, your purchaser, your engine builder, or your tuner how many turbo kits they fabricated. Might as well be asking Shirley Temple how many mob bosses she knocked off.

Leave a comment:

-

thank you, very well stated.Originally posted by NateD4 View PostI'll inject some of my 0.02$ into the mix.

There seems to be a lot of partial information floating around here.

But the experienced are largely right. You don't need perfect to make power with boost.

What you really need to do is define your mission. Then realize that the operating range you are targeting might be too wide for optimizations.

NASCAR spends time chasing renege of HP because they are rule bound. Most back yard builders aren't.

You can calculate until you turn colors, however you'll discover your math is only 80% accurate 80% of the time.

-----------

Turbos require back pressure to operate so your manifold isn't exposed to atmospheric pressure. Additionally the turbine inlet is a nozzle designed to accelerate the pressure in the manifold into kinetic energy (think total pressure and static pressures).

The requirements are very different from a NA manifold.

Leave a comment:

-

actually if you do a little digging you will see some of the work that has been done by respectable viper shops is so so to border line hack work. there are plenty of horror stories about kits that are poorly built coming from respected shops in that market.Originally posted by HOYS View PostComing from Jon who has designed, built, tested, and mass produced turbo kits that were regarded as some of the best out there for some cars...he is worth a listen.

He is not saying you shouldn't make collectors...but your time, effort, and money could be used for something else more productive. If this was high dollar racing where every single HP was worth the time to get it, you would have no problems. This is a forum about an engine that came in mini-vans, grocery getters, and that's about it.

Viper forums? You make those collectors all day.

Leave a comment:

-

I'll inject some of my 0.02$ into the mix.

There seems to be a lot of partial information floating around here.

But the experienced are largely right. You don't need perfect to make power with boost.

What you really need to do is define your mission. Then realize that the operating range you are targeting might be too wide for optimizations.

NASCAR spends time chasing renege of HP because they are rule bound. Most back yard builders aren't.

You can calculate until you turn colors, however you'll discover your math is only 80% accurate 80% of the time.

-----------

Turbos require back pressure to operate so your manifold isn't exposed to atmospheric pressure. Additionally the turbine inlet is a nozzle designed to accelerate the pressure in the manifold into kinetic energy (think total pressure and static pressures).

The requirements are very different from a NA manifold.

Leave a comment:

Leave a comment: