Announcement

Collapse

No announcement yet.

roller lifters with 2.8

Collapse

X

-

Im interested in what the main bearings look like as well as the main webbing. Im also wondering if the engine encountered some knock due to fuel starvation? Seems like all went downhill after the developed an intermittent miss that seemed to occur in the corners.

-

Hmm the VVT 3500 has a shorter stroke. I think it's even the same as the 2.8 stroke IIRC. Anyone know if it's forged like the 3900 crank?

Leave a comment:

-

Wow! Well its good to know that the chain was not the problem. Don't know if it is possible to get the small displacement that you need, but I would see how much a 3500 crank can be de-stroked. If you can turn it down enough you could use a 3400/3500 block and have a big bore short stroke 2.8...

Leave a comment:

-

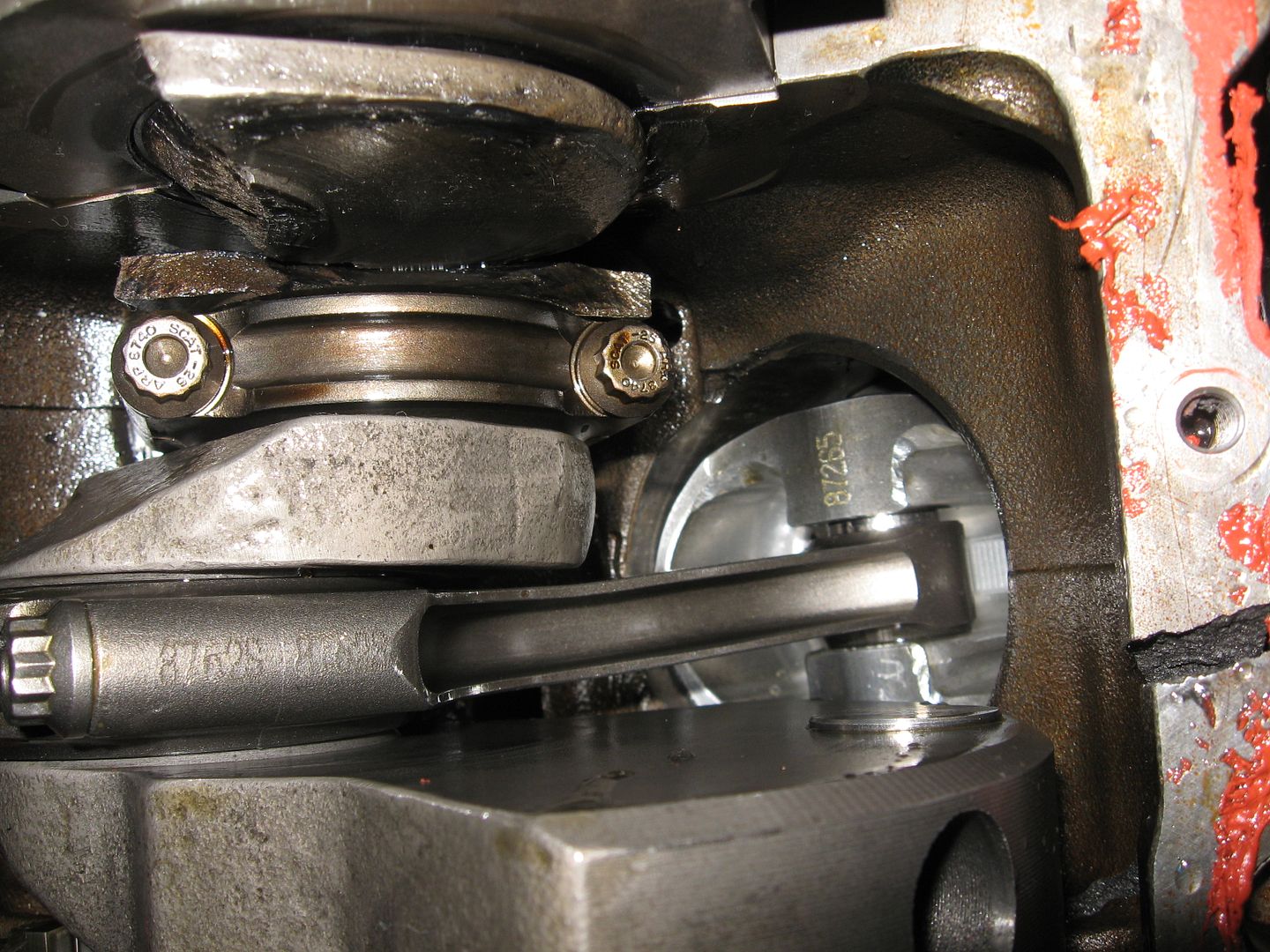

Correct me if I'm wrong but it looks like the mains started to go and the heat from that fatigued that small portion of the crank (and damn it's amazing to see how little of an area holds it together) which then caused it to break and all hell break loose...

Leave a comment:

-

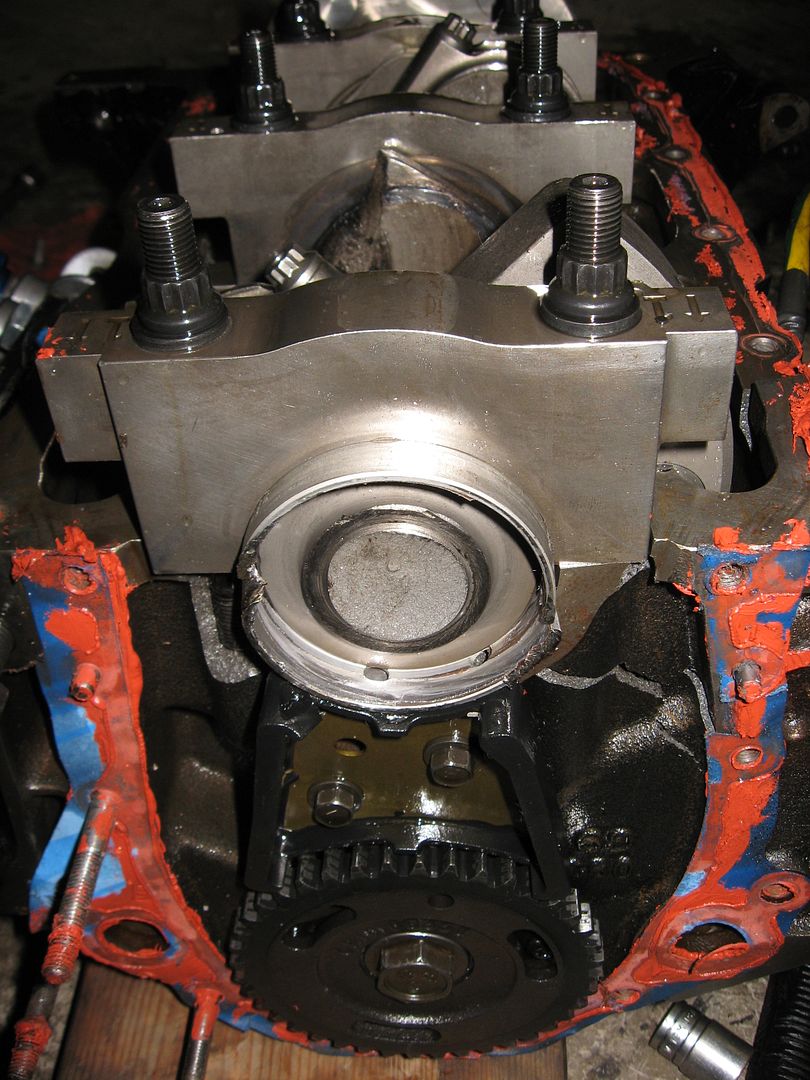

The camshaft chain is OK, it is original GM product.

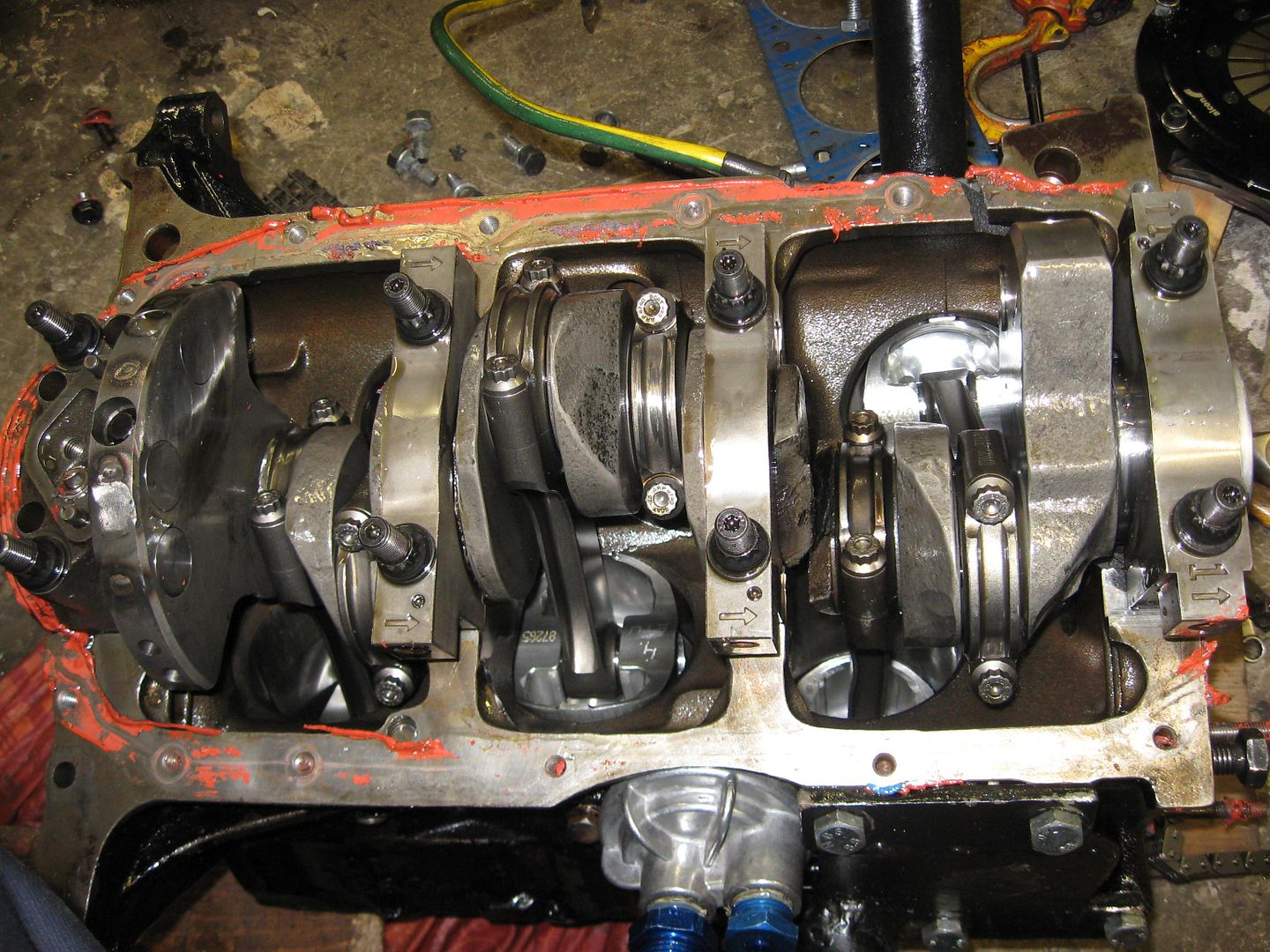

The crank has snapped between #2 and #3 cylinders.

2 connecting rods look like bananas.

Leave a comment:

-

Would not be surprised if the crank broke between the main and #5 rod throw first and the sudden stop sheared the damper off. Had that happen to me on a blown 2.8 but did not have NEAR the carnage of this!

Leave a comment:

-

IIRC it was a stock GM setup but who's to say the chain itself broke? He wont know till he pulls the motor... sounds like the chain will be 100% intact and the crank is what gave out.

Leave a comment:

-

What timing chain was used in this build? If it was a stock chain you may have found the breaking point...

Leave a comment:

-

LOLOriginally posted by veekuusi View PostThank god , Greenpeace was not in attendance.

and you make a good point, if the crank did shear right behind the cam gear then the hardened pushrods and the pistons coming up would easily break the heads that way... especially if the valves didn't give much either.

Leave a comment:

-

What went first?Originally posted by 3400-95-Modified View PostThe question is what went first.... I find it hard to believe the breaking of the crank would damage the heads that badly... I'm wondering if they are just not up to par for the RPM and cam he's running and that valve train failure stopped the engine dead which in turn spun the front of the crank right off due to the inertia the harmonic balancer had.

And Unchained01 the harmonic balancer was needed to eliminate the bad harmonics of the engine... it does not weight balance it.

Good question.

I do not have time to open the oil pan until the weekend.

Interesting to see the damage.

But I suppose it went this way:

First the crankshaft broke , the broken point is where the timing chain lower

gear is located.

That is why the camshaft did not rotate any more.

Crankshaft kept spinning.

Valves hit the pistons.

Pushrods are "heavy duty", they did not pend.

The rockers studs were forced to go off the cylinder heads.

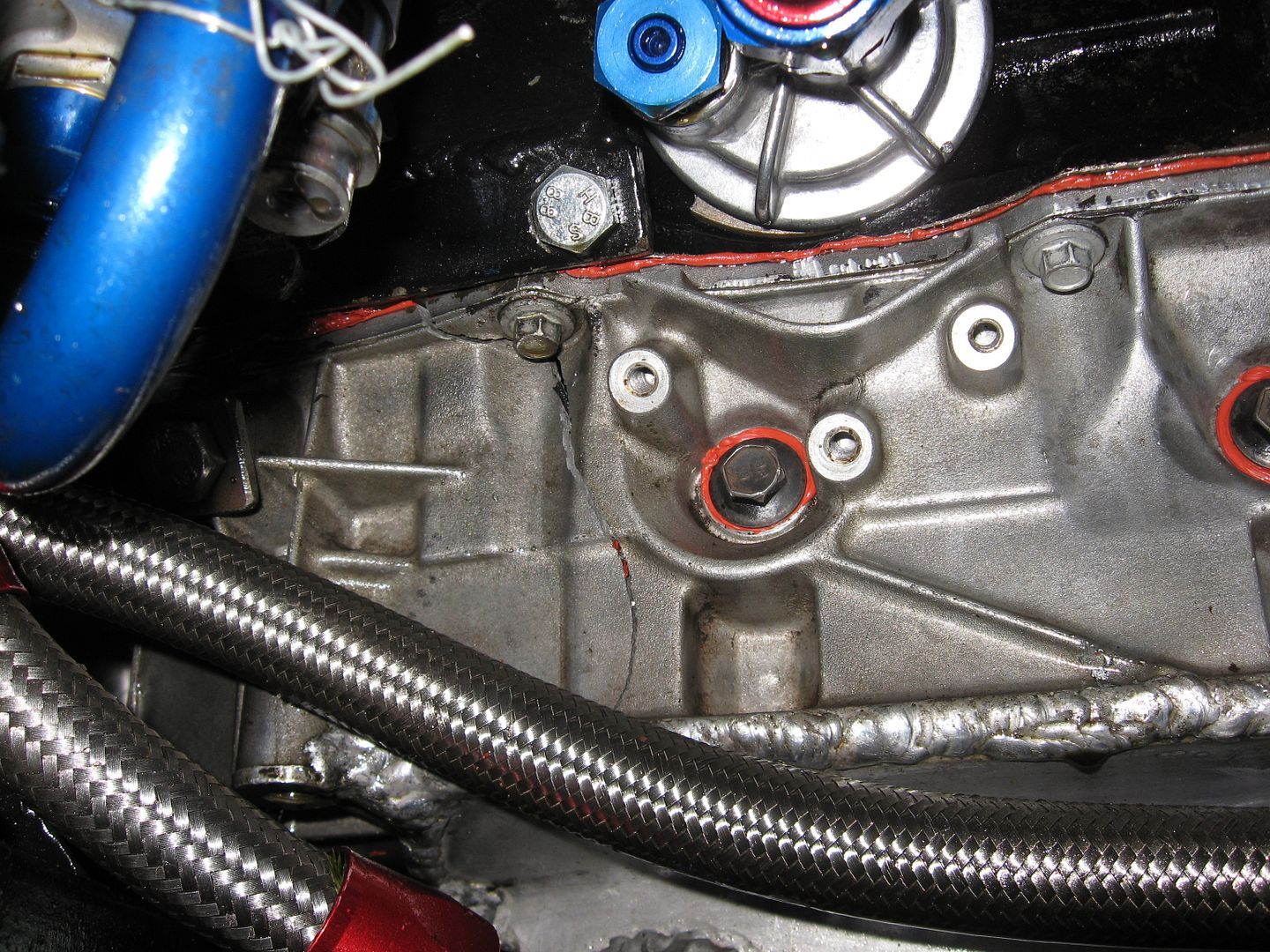

Fracture in the oil pan .

Damage to the oil sump tank and to the hall sensor.

10 litres of oil spilled to the track.

Thank god , Greenpeace was not in attendance.Last edited by veekuusi; 06-10-2014, 12:53 PM.

Leave a comment:

-

The question is what went first.... I find it hard to believe the breaking of the crank would damage the heads that badly... I'm wondering if they are just not up to par for the RPM and cam he's running and that valve train failure stopped the engine dead which in turn spun the front of the crank right off due to the inertia the harmonic balancer had.

And Unchained01 the harmonic balancer was needed to eliminate the bad harmonics of the engine... it does not weight balance it.

Leave a comment:

-

Too bad you have to use the short stroke. The 3500 came with much better cranks, but I believe you said earlier that you are limited to displacement for your class?

Leave a comment:

Leave a comment: