This thread is a continuation of this thread:

This story is to get a winning engine to a historic race car.

GM 2.8 V6 push rod engine in a 1974 Ford Capri.

-block 1996 3.1 (gen 3)FWD bore 89.25 , stroke 76 mm

-3400 aluminum heads (gen 3)

-custom billet Crower

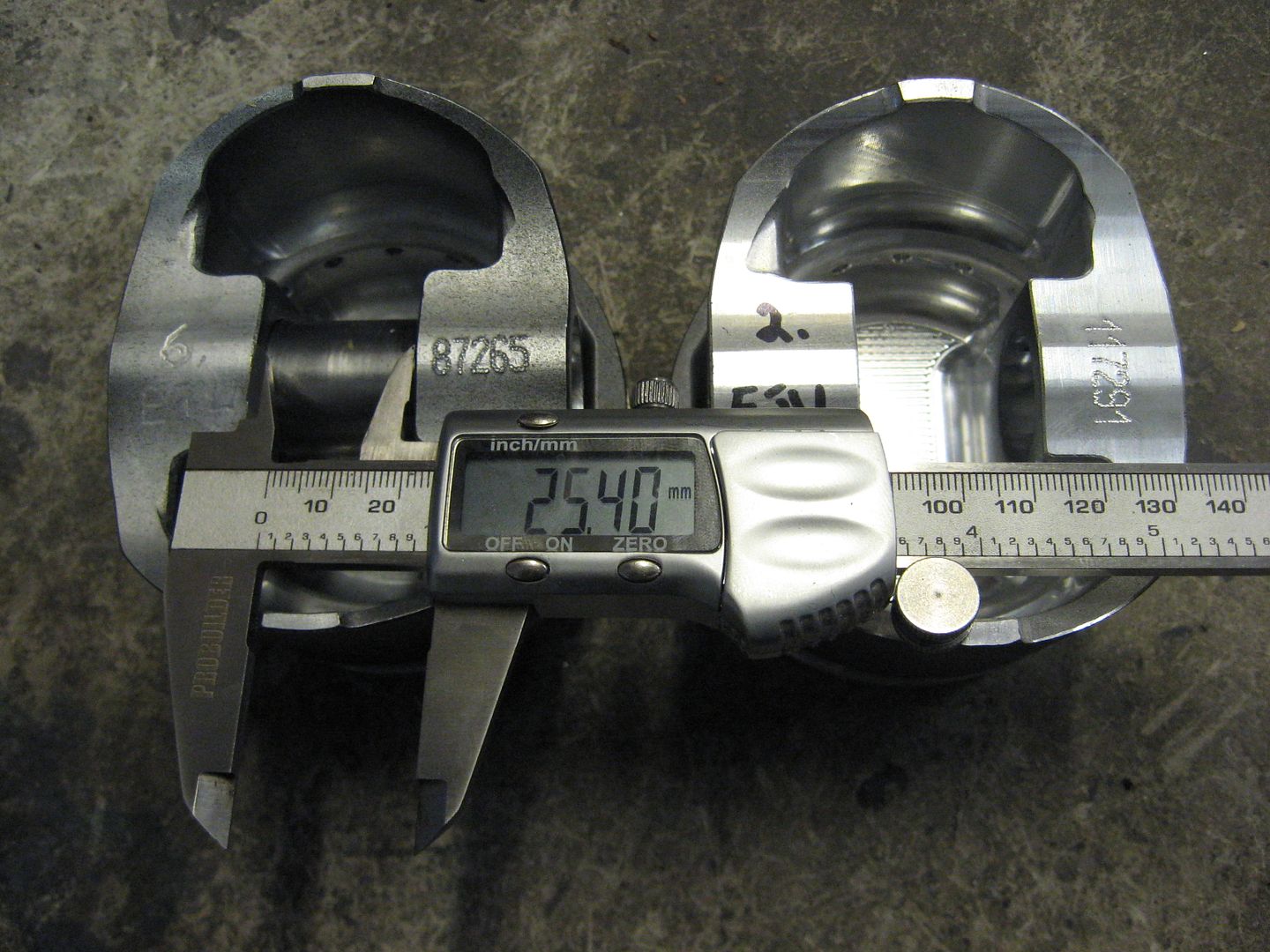

-pistons Diamond custom

-Total Seal piston rings

-Manley stainless steel valves 1.76" / 1.42"

-camshaft Schneider 258/264 (.050") , lobe separation 106 , valve lift 13.2 mm (0.520")

-mechanical roller lifters (Crane)

-double custom valve springs closed 175 lbs, open 445 lbs

-roller rockers (Crane) 1.6:1

-custom push rods (Comp Cams)

-compression ratio 12:1

-Scat connecting rods 5.700"

-custom intake

-2 Weber 45 mm carbs

-ignition 6 x 034 Motorsport coils

-ECU Gems EM36

-spark plugs NGK BCR8ES

-custom exhaust 38 mm ID 3-> 1

-ATI damper

-electic water pump Davies Craig (EWP 115)

-dry sump AT-Power (3 stage)

-bellhousing Chevy S-10 5-speed (82-92)

-2 disc Alcon clutch

-gearbox 5-speed "dog box" Sellholm M47000

A had a total engine loss bacause of crankshaft cracked june 2014 (first race in this season).

Pretty much damage.

The race season 2014 was over.

I have in my garage all the other parts for the new engine except one.

The crankshaft.

The old one was original cast crank.

I ordered a new billet crankshaft from Crower.

I have not yet seen it ,

the latest news is that it should be ready "mid October".

There has been lots of enquirys, what is going on with this project.

I am sorry to put no input here in this forum.

But hopefully I have now time and motivation to go on ,

and we can see a better and winning engine in my car the race season 2015.

This story is to get a winning engine to a historic race car.

GM 2.8 V6 push rod engine in a 1974 Ford Capri.

-block 1996 3.1 (gen 3)FWD bore 89.25 , stroke 76 mm

-3400 aluminum heads (gen 3)

-custom billet Crower

-pistons Diamond custom

-Total Seal piston rings

-Manley stainless steel valves 1.76" / 1.42"

-camshaft Schneider 258/264 (.050") , lobe separation 106 , valve lift 13.2 mm (0.520")

-mechanical roller lifters (Crane)

-double custom valve springs closed 175 lbs, open 445 lbs

-roller rockers (Crane) 1.6:1

-custom push rods (Comp Cams)

-compression ratio 12:1

-Scat connecting rods 5.700"

-custom intake

-2 Weber 45 mm carbs

-ignition 6 x 034 Motorsport coils

-ECU Gems EM36

-spark plugs NGK BCR8ES

-custom exhaust 38 mm ID 3-> 1

-ATI damper

-electic water pump Davies Craig (EWP 115)

-dry sump AT-Power (3 stage)

-bellhousing Chevy S-10 5-speed (82-92)

-2 disc Alcon clutch

-gearbox 5-speed "dog box" Sellholm M47000

A had a total engine loss bacause of crankshaft cracked june 2014 (first race in this season).

Pretty much damage.

The race season 2014 was over.

I have in my garage all the other parts for the new engine except one.

The crankshaft.

The old one was original cast crank.

I ordered a new billet crankshaft from Crower.

I have not yet seen it ,

the latest news is that it should be ready "mid October".

There has been lots of enquirys, what is going on with this project.

I am sorry to put no input here in this forum.

But hopefully I have now time and motivation to go on ,

and we can see a better and winning engine in my car the race season 2015.

Comment