Announcement

Collapse

No announcement yet.

Porting suggestions/pics for 3x00 heads

Collapse

X

-

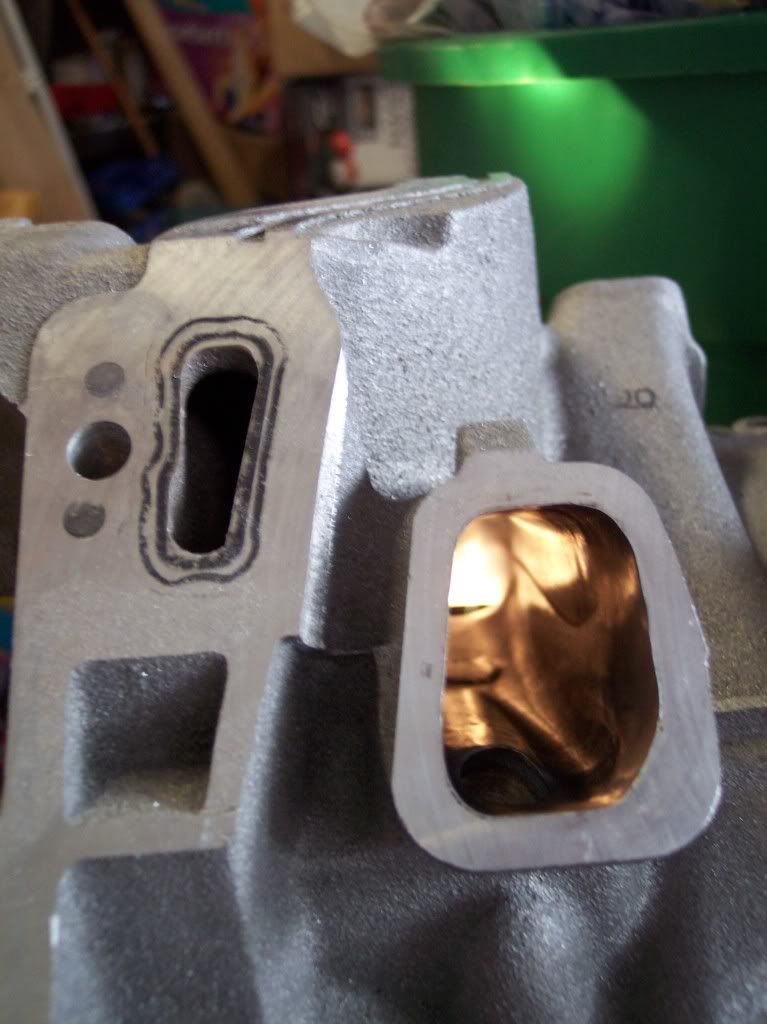

Sure is shiny! I can see a casting seam though still in the runner! hehe.

Leave a comment:

-

Completely finished the first runner, how do you like?

The dowel worked great. Drilled a hole in the end of it and stuck a spherical stone in there. Then cut a slot in the end and wrapped a strip of sand paper to make a paper drum/flapper, then cotton buffed it.

Leave a comment:

-

I didn't need to drop the RPM. My problem was that, with the big bulky trigger, you still had to hold it down all the time and that kind of limited how I could hold the grinder. With the dremel, I just set the speed switch and went to town.Originally posted by ikessky View PostI just use an air regulator to drop the RPM of the die grinder. That way, I can just hold the trigger all the way down rather than trying to feather it.

Leave a comment:

-

Had a few minutes today after moving 2 apartments of furniture for family members. I'm satisfied with the job so far...

Leave a comment:

-

Sounds like when I beat a 2.5" pipe to fit my t3 turbo flange. I tacked it, beat it, tacked it, beat it etc etc. Came out nice, though.Originally posted by Superdave View Post1 5/8" worked perfect.. although beating the ends into a D shape wasn't the most fun i've ever had.. that's why i used round ports on the last set i built.

Look at the shiney ...

...

3400-95-modified thanks for the flapper suggestion! I used 80, 120, then a cotton buffing wheel. Probably can skip the 80 on the rest because the stone does a nice job.

I also think I am going to try and use a dowel, dill a hole in the end, and glue a Dremmel bit in it, so I can put in a drill and get the entire runner length as nice as I can.Last edited by ForcedFirebird; 09-25-2007, 05:56 PM.

Leave a comment:

-

1 5/8" worked perfect.. although beating the ends into a D shape wasn't the most fun i've ever had.. that's why i used round ports on the last set i built.

Leave a comment:

-

I just use an air regulator to drop the RPM of the die grinder. That way, I can just hold the trigger all the way down rather than trying to feather it.Originally posted by whitelightnin04MC View PostThe dremel was much better for me because there wasn't a bulky trigger that I had to hold down. With the dremel, I just set the rpm and went to work.

Leave a comment:

-

You have your secrets as you very well should, Bill Gates doesn't release his windows code for the same reasonOriginally posted by SappySE107 View PostThe port entrance shouldn't screw anything up if you gasket match. I prefer to leave the floor alone, or just barely go over it to make it look nicer. I can't say any more on this subject.

Leave a comment:

-

Why for me? Because I'm going with boost? I know I don't want to loose velocity, but at the same time the turbo is going to need all the gas/heat I can get to it.Originally posted by Superdave View Postfor you, i don't know how much i'd cut out of the exhaust ports. they are pretty large as it is. If i remember right the middle port is offset slightly on the 3500 VS the 3400 gaskets so I adjusted the shape of that one a little.

Yeah, I saw a little difference betweent the 3400 and 3500 heads when I was comparing the two sets I had here. I thought all three of the 3500 ports looked like they were more vertical, but didn't actually measure it.

Also, I saw you used 1 5/8" primaries? Could they be beat close to the shape of the ports? I think I have some 1 5/8" in the garge, was going to experiment before I spent a bunch of money on 180* mendrels.

Leave a comment:

-

for you, i don't know how much i'd cut out of the exhaust ports. they are pretty large as it is. If i remember right the middle port is offset slightly on the 3500 VS the 3400 gaskets so I adjusted the shape of that one a little.

i used stock Felpro gaskets for a 3400, had to adjust them a little to clear the header flanges but that's easy.

here is the stock 3400 gasket on the 3500 head The far left port is how far I ported them out, the other 2 are stock:

.jpg)

Leave a comment:

-

And the exhaust? You said, Dave, to port to the 3400 gaskets? I also need velocity on the exhaust side because this motor will be feeding a turbo soon. Where did you get said gaskets?

Leave a comment:

-

yes, just sand the floor lightly. Don't change the short side radius of the port at all.

Leave a comment:

-

Because you said what you have to, or because you don't want to know your secretsOriginally posted by SappySE107 View PostI can't say any more on this subject. , JK I'll take any advice I can since this is my first port job on a 660.

, JK I'll take any advice I can since this is my first port job on a 660.

Leave a comment:

-

The port entrance shouldn't screw anything up if you gasket match. I prefer to leave the floor alone, or just barely go over it to make it look nicer. I can't say any more on this subject.

Leave a comment:

Leave a comment: