Announcement

Collapse

No announcement yet.

Porting suggestions/pics for 3x00 heads

Collapse

X

-

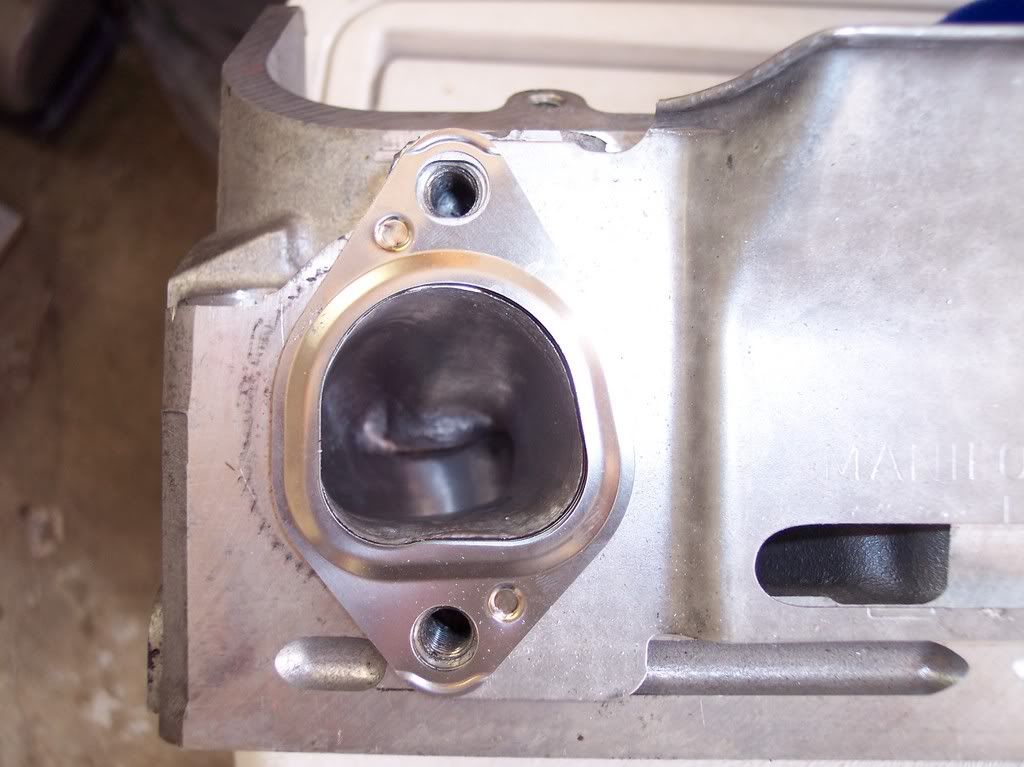

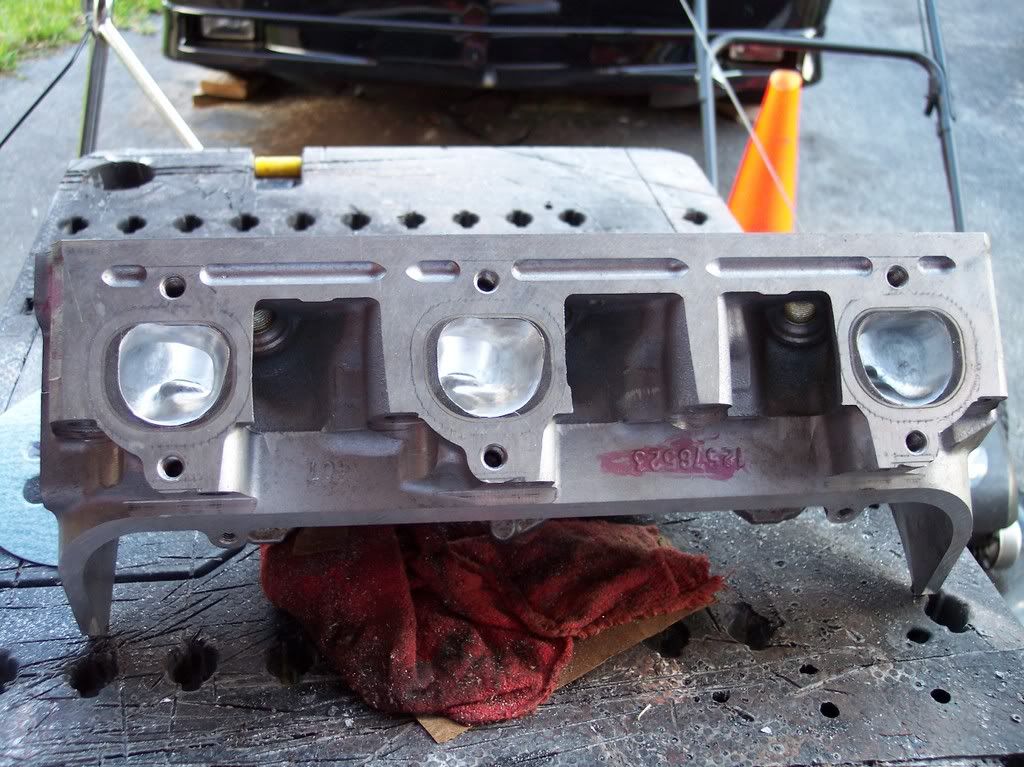

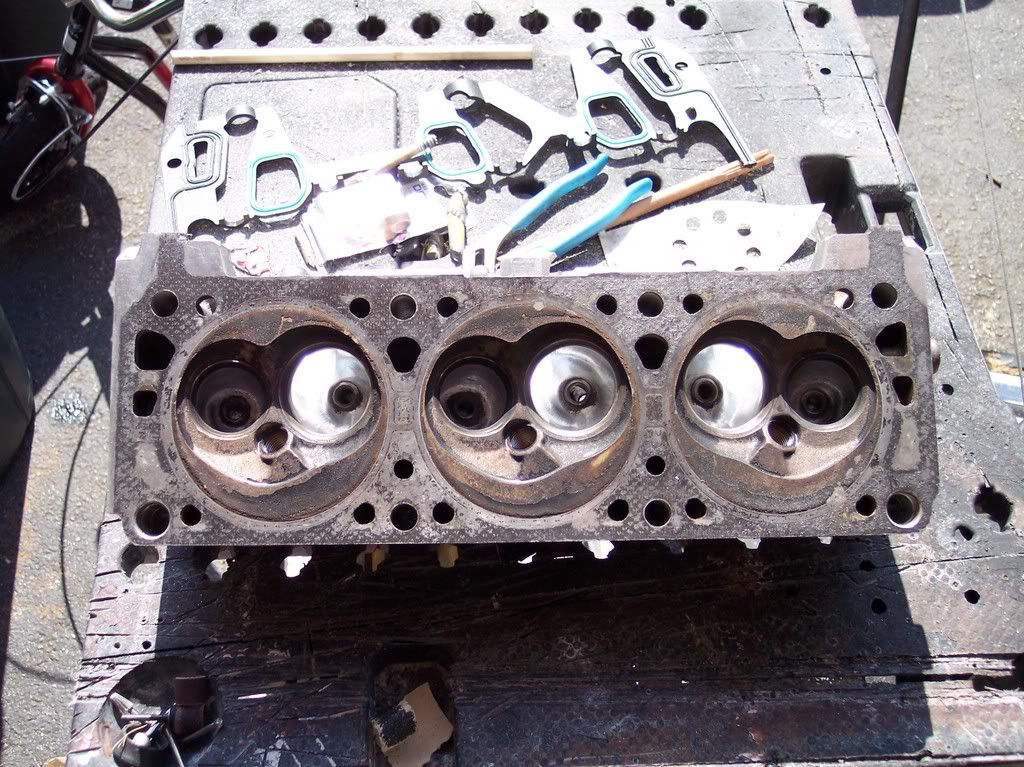

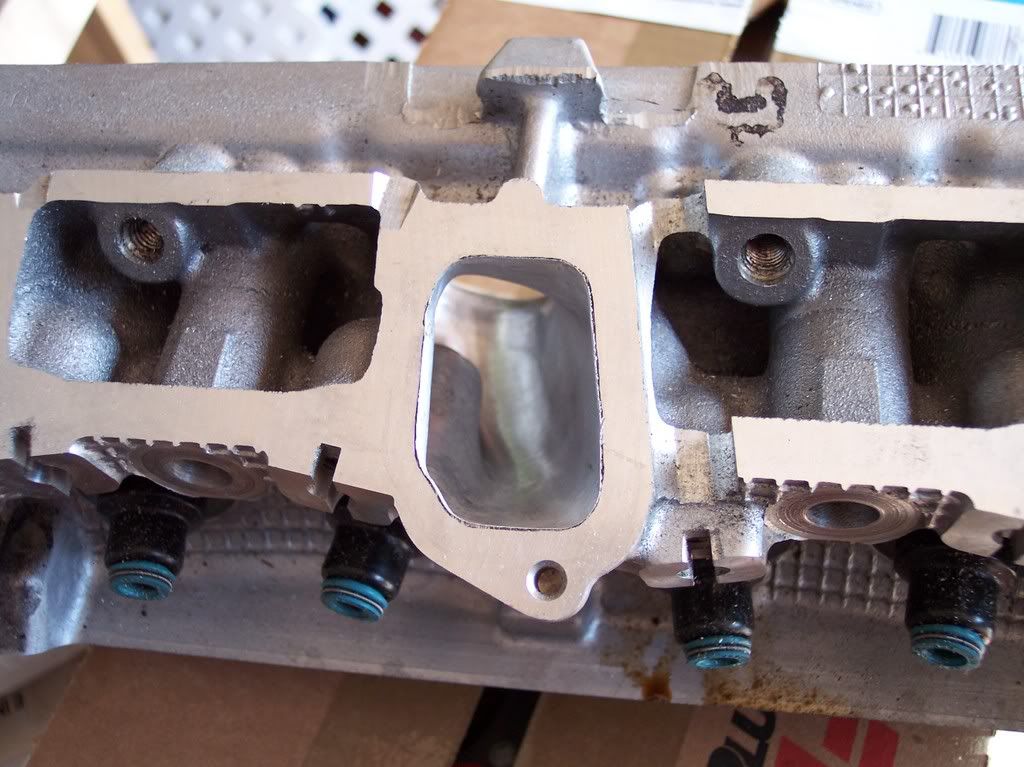

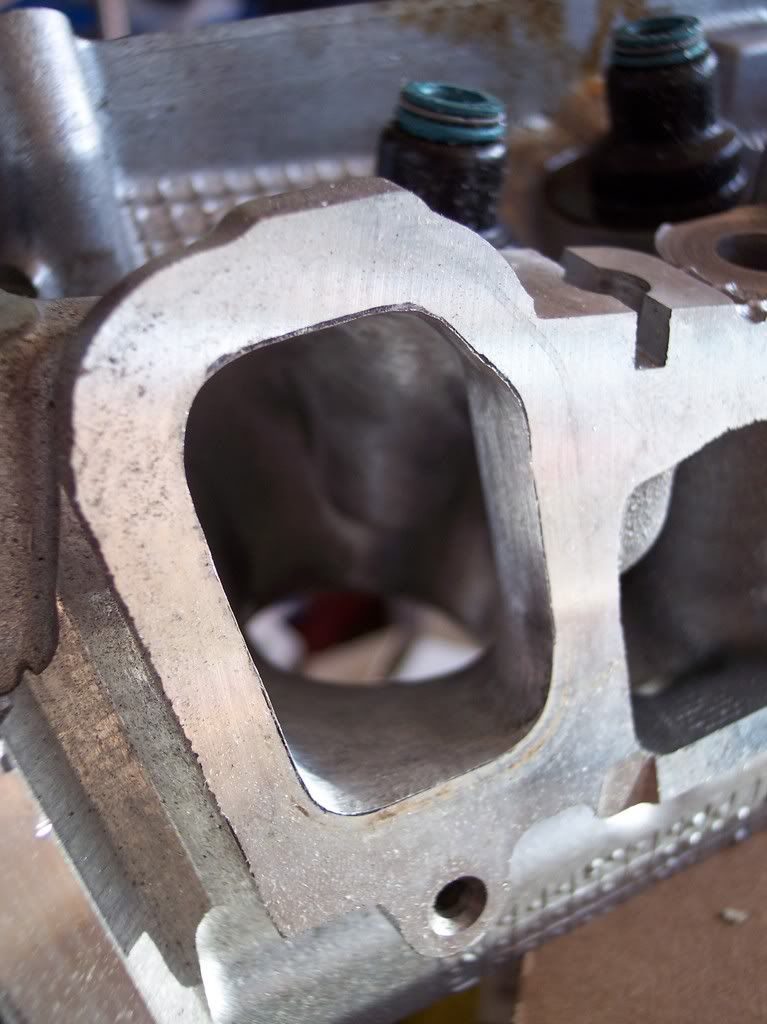

Per Ben's suggestions, I only gasket matched, and just smoothed out all the casting marks/seams.Originally posted by zofo61 View PostNice!......just gasket matching?....Going to do any bowl work....or angles?

Leave a comment:

-

Nice!......just gasket matching?....Going to do any bowl work....or angles?

Leave a comment:

-

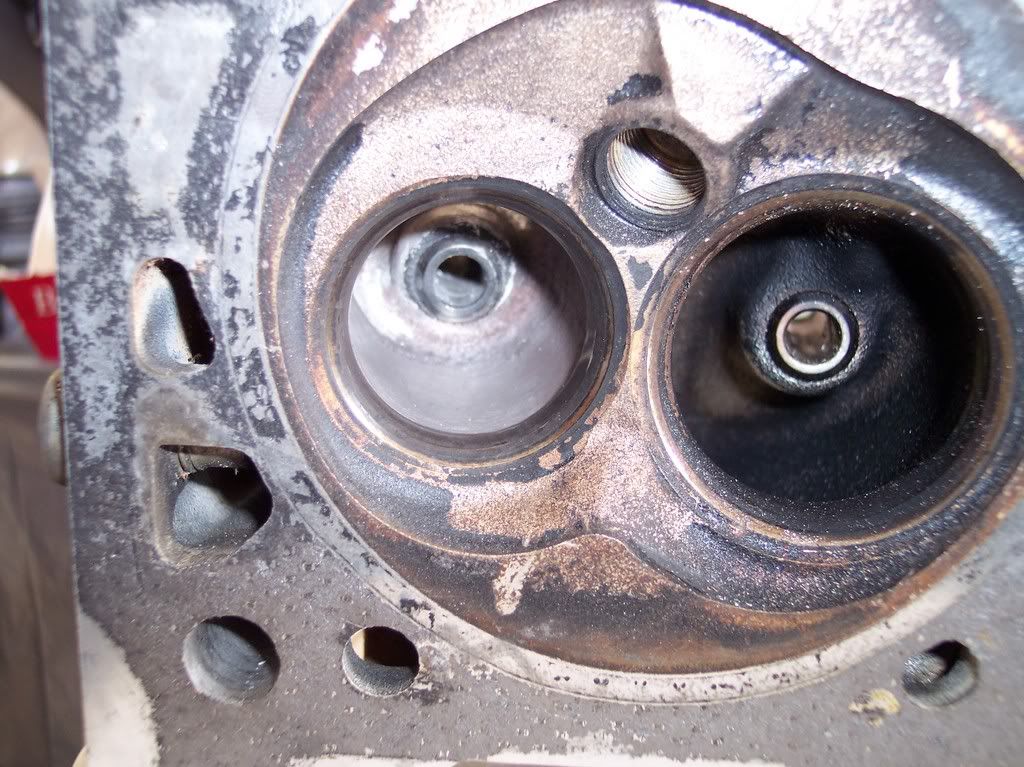

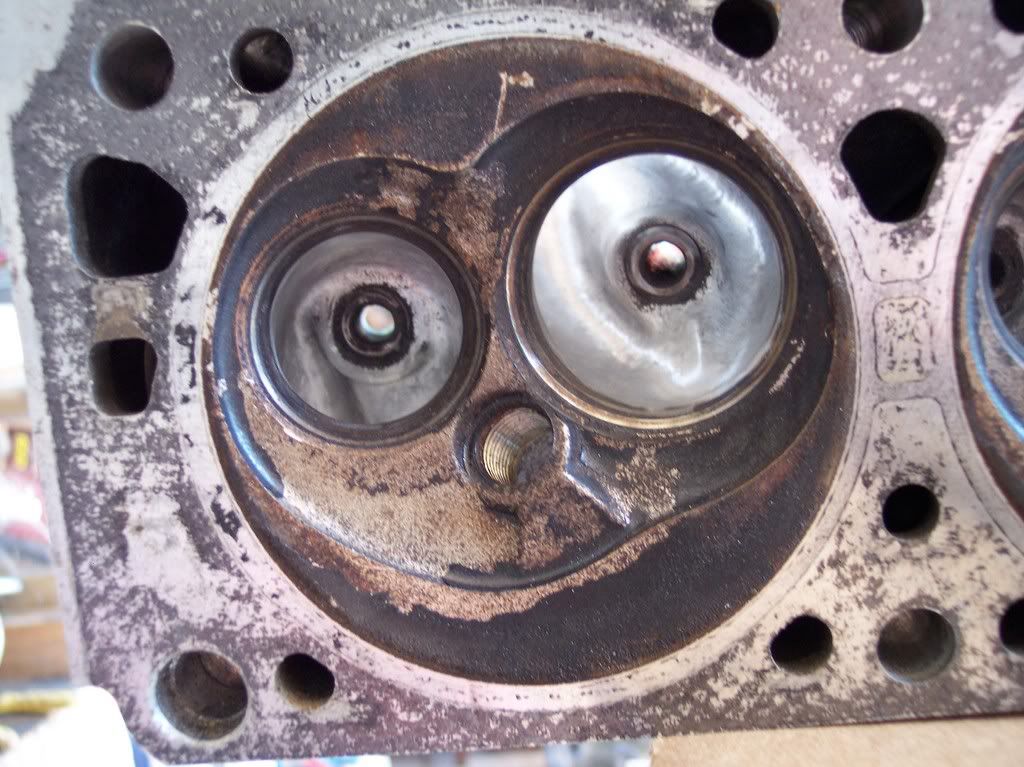

Started porting the exhaust today, but how do you get that tight area around the guides? It's probably good enough, but I'm a bit of a perfectionist :P ...

Leave a comment:

-

That's been posted before. I remember seeing it. Like Ben says though careful on what you're porting sometimes you can hurt velocity.

I remember seeing it. Like Ben says though careful on what you're porting sometimes you can hurt velocity.

Leave a comment:

-

Please post pics as soon as you have made some progess....I am interested in doing a set of 3500 heads for boost as well.............

Leave a comment:

-

Yeah you'll be fine. I wouldn't worry about the casting seam too much. In my 97 3400 plenum it was visible but didn't stick out or feel like a bump to the touch so I left it alone. The 94 3100 casting was waaay rougher with irregular square notches on the top round ports (???) and the cast was super rough. The 97 3400 was very smooth inside, no rough sand feel at all.

Yeah you'll be fine. I wouldn't worry about the casting seam too much. In my 97 3400 plenum it was visible but didn't stick out or feel like a bump to the touch so I left it alone. The 94 3100 casting was waaay rougher with irregular square notches on the top round ports (???) and the cast was super rough. The 97 3400 was very smooth inside, no rough sand feel at all.

Leave a comment:

-

Actually I was using 120 to finish the runners, then buffing them with a cotton buffer and red compound to get the mirror finish. Perfect, I'll just leave them at 120. I thought 120 would be a little too smooth to prevent fuel coagulation.Originally posted by SappySE107 View PostI use 120 so yeah, 80 is perfectly fine.

Leave a comment:

-

Nope, as I stated earlier I will polish it to the injectors.Originally posted by SappySE107 View PostI wouldn't polish it leading from the lower to the head.

80 grit rough enough after?

Leave a comment:

-

Issac: Fangu! I was going to smooth the casting marks too, but the block will be here Thursday and I'm trying to make the Southern V6 Clash in March (N/A). I think they will be just fine

I was going to smooth the casting marks too, but the block will be here Thursday and I'm trying to make the Southern V6 Clash in March (N/A). I think they will be just fine  .

.

Modified: I will be N/A and posing dyno results before returning the boost. 11:1 compression is a little much for a turbo, so until I get the 3400 pistons I'm working on, this will be all motor.

Leave a comment:

Leave a comment: