Announcement

Collapse

No announcement yet.

Porting suggestions/pics for 3x00 heads

Collapse

X

-

I bought a pneumatic die grinder for porting my 3500 upper. After the third port, I switched back to my dremel. Our air compressor doesn't have a really large holding tank and the compressor was running almost non stop. The dremel was much better for me because there wasn't a bulky trigger that I had to hold down. With the dremel, I just set the rpm and went to work.

-

Here's what 25min got me...

What's left of the sphere after the UIM and the top of one runner, though. Going to get some more now...

Leave a comment:

-

$$, the stones work fast enough for me. I don't do this everyday.Originally posted by SappySE107 View PostCarbide burrs work faster and last longer and don't clog up nearly as bad. Makes life easier with aluminum.

BTW: RotoZip spins @ 30,000 RPM (with the force of a hand drill), 14k is the angle grinder. MY collet on the Zip can go from 1/4" down to 1/16".

Leave a comment:

-

Carbide burrs work faster and last longer and don't clog up nearly as bad. Makes life easier with aluminum.

Leave a comment:

-

Note in pic 4 of post #30, there is a wire brush. Halfway between each port, I would hit the wire brush on the stone while the Zip was running . I buy the stones for $7 for an assorted pack at Harbor Freight, and at 14k RPM, they work great as long as you don't press too hard. They cut really fast if you just barely touch the aluminum. I'm still going to sand to make them nice and shiney

. I buy the stones for $7 for an assorted pack at Harbor Freight, and at 14k RPM, they work great as long as you don't press too hard. They cut really fast if you just barely touch the aluminum. I'm still going to sand to make them nice and shiney

EDIT: The sphere just didn't get hit with the brush after I was finished, the pink stone did.Last edited by ForcedFirebird; 09-23-2007, 12:59 AM.

Leave a comment:

-

Looks like one of his stones did start to load up, mostly the round white one.... A trick to use stones on aluminum/soft metal is to soak the stones in kerosene and keep plenty on the stone while grinding. Another trick for grinding soft metals is to load the grinding wheel with bees wax. THAT is messy tho. Stick with kero. It will also give a MUCH better finish!!

Tom

Leave a comment:

-

I can't believe you used a stone on aluminum. Looks like it turned out well but stones clog up fast on aluminum. zephyrhillis sounds like an STD to me:P

Leave a comment:

-

Hmmm. You work fast. Must be the rotozip. Between my die grinder and dremel it took me forever. Of course I also ground the plenum neck, took of the square, and side and front tabs, took off the casting seams too.

Leave a comment:

-

I meant bits, you butt!Originally posted by bszopi View PostPlease keep these to yourself, and your wife.

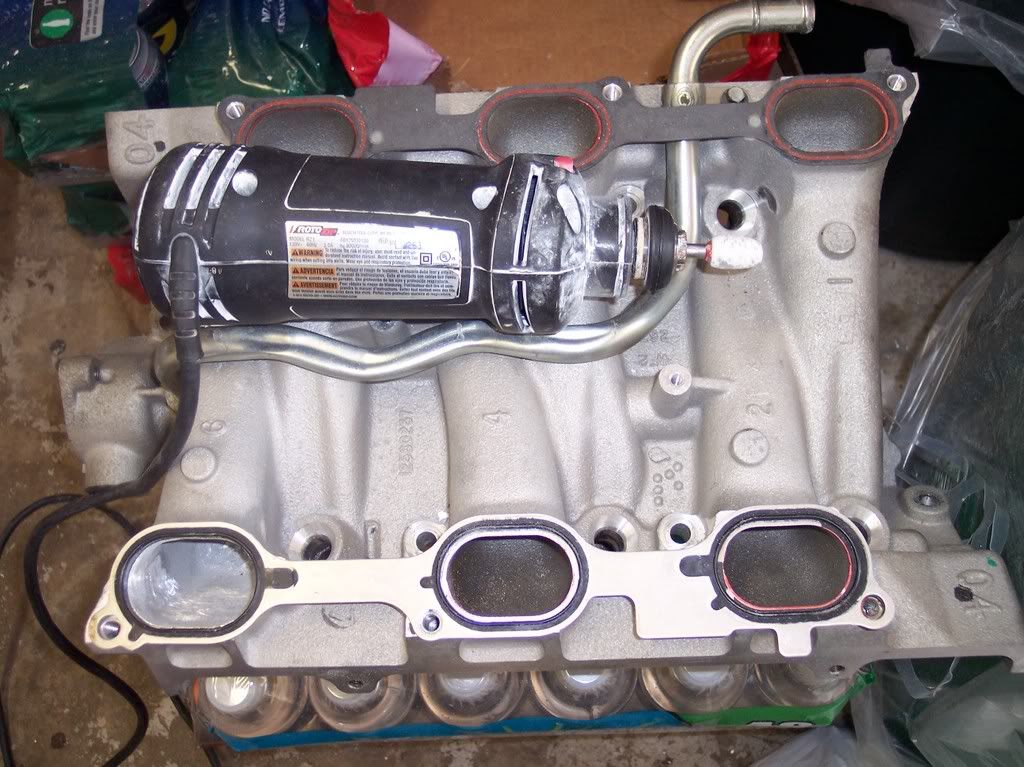

Got the UIM done tonight. Spent about 2hrs on it total. First a gasket match, then radiused the inside...

Changed bits. Couldn't find my outside radius stone, so I went with a sphere...

^^^ tough to take a pic of the inside!

Leave a comment:

-

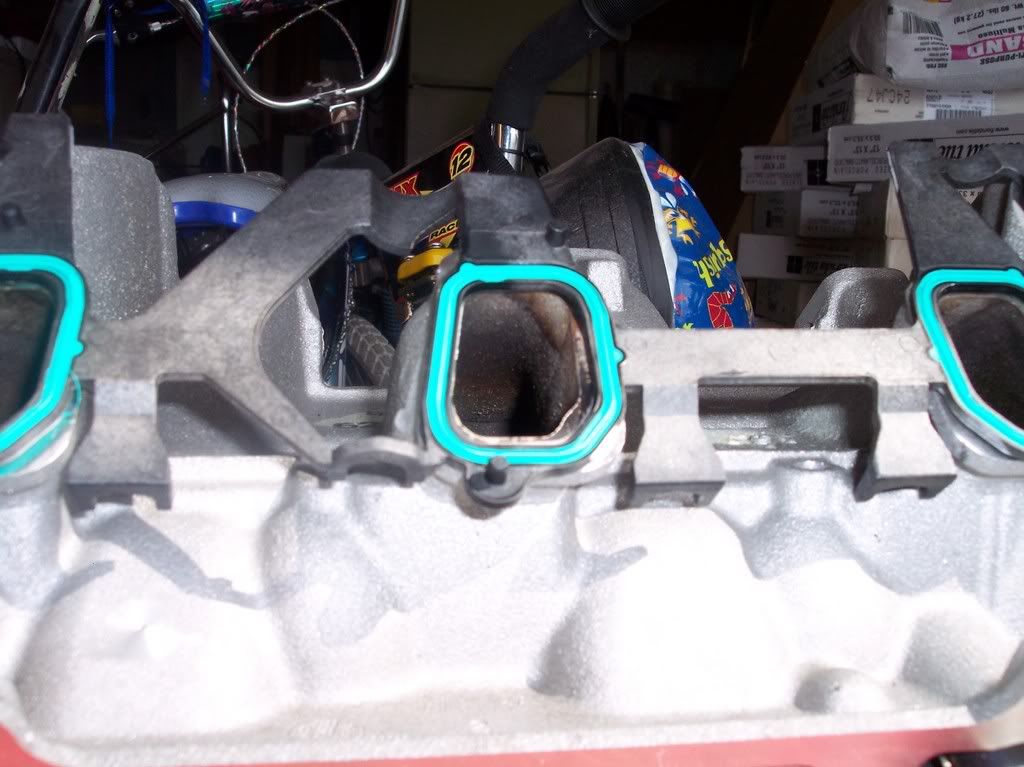

I plan to radius the inside of the plenum. Going to see if I can get the inside of the TB neck smooth, too.

For grinding, I will be using my RotoZip. It never runs out of air I have a nice radiusing but, I'll get pics up later. When I get close, file is nice on aluminum.

I have a nice radiusing but, I'll get pics up later. When I get close, file is nice on aluminum.

I have strips of sand cloth to get the inside of the runners, and am going to make a drum with a long extension to get the rest.

Too bad I didn't have time to sit down and put this into the CNC while I was at it. Then they all would have a perfectly smooth finish, and all would be exactly the same. Some areas would still have to be done by hand regardless.

Leave a comment:

-

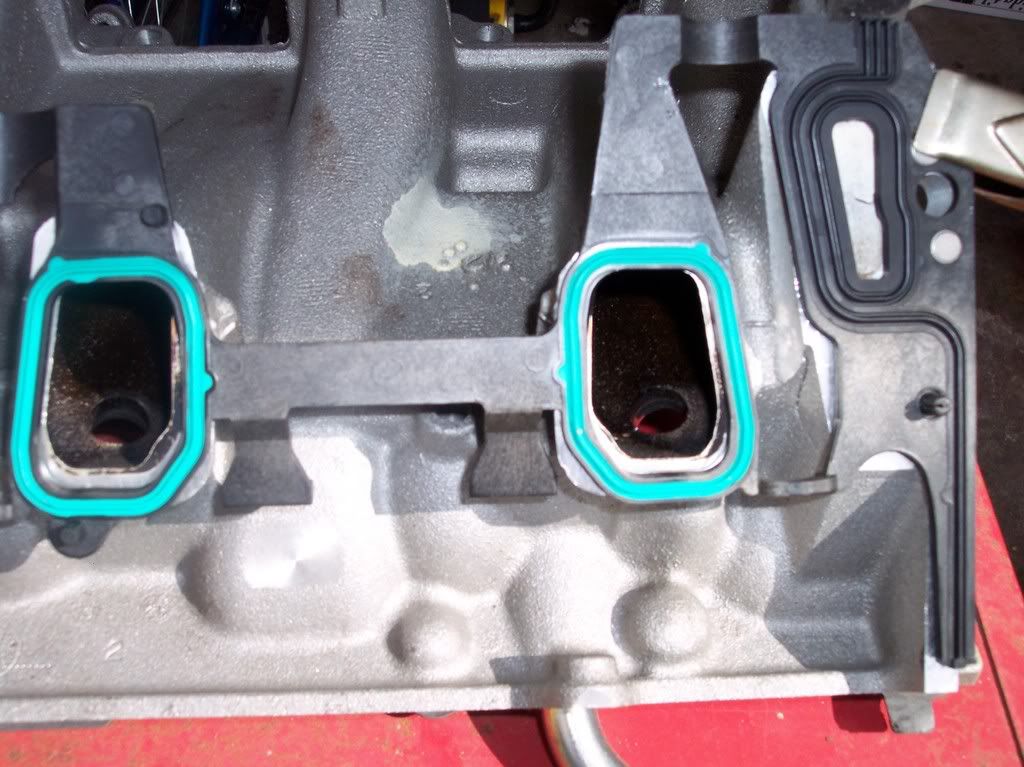

Bell-mouth the plenum ports too. Be careful of the LIM gasket matching, as the gasket when bolted down shifts and is in a different spot. When it's just lying on the intake it's not in it's final position until the rubber is smashed down tight.

What do you guys use to port? I have an air die grinder and a stone wheel, but it takes forever. Granted I only have about 6 secs before the air tank is empty, but even then it doesn't take much metal off...

Leave a comment:

-

Actually scratch the last question, with the heads and LIM bolted together, the gaskets line up with the center port more like the others, and sill going to have to remove some material from the floor.

Leave a comment:

-

Looking at the LIM, there is a lot of work to do. The UIM won't be so bad since it's just thin aluminum to clearance.

And what do you do in a situation where the gasket extends to the inside of the port? I just noticed what looks the stain from fuel puddeling there. should I trim the gasket a bit, or just leave it?...

Leave a comment:

-

You rock! Too bad you live in the boonies, or we would have a lot to do with all the toys between you and I.Originally posted by SappySE107 View Post

Leave a comment:

Leave a comment: