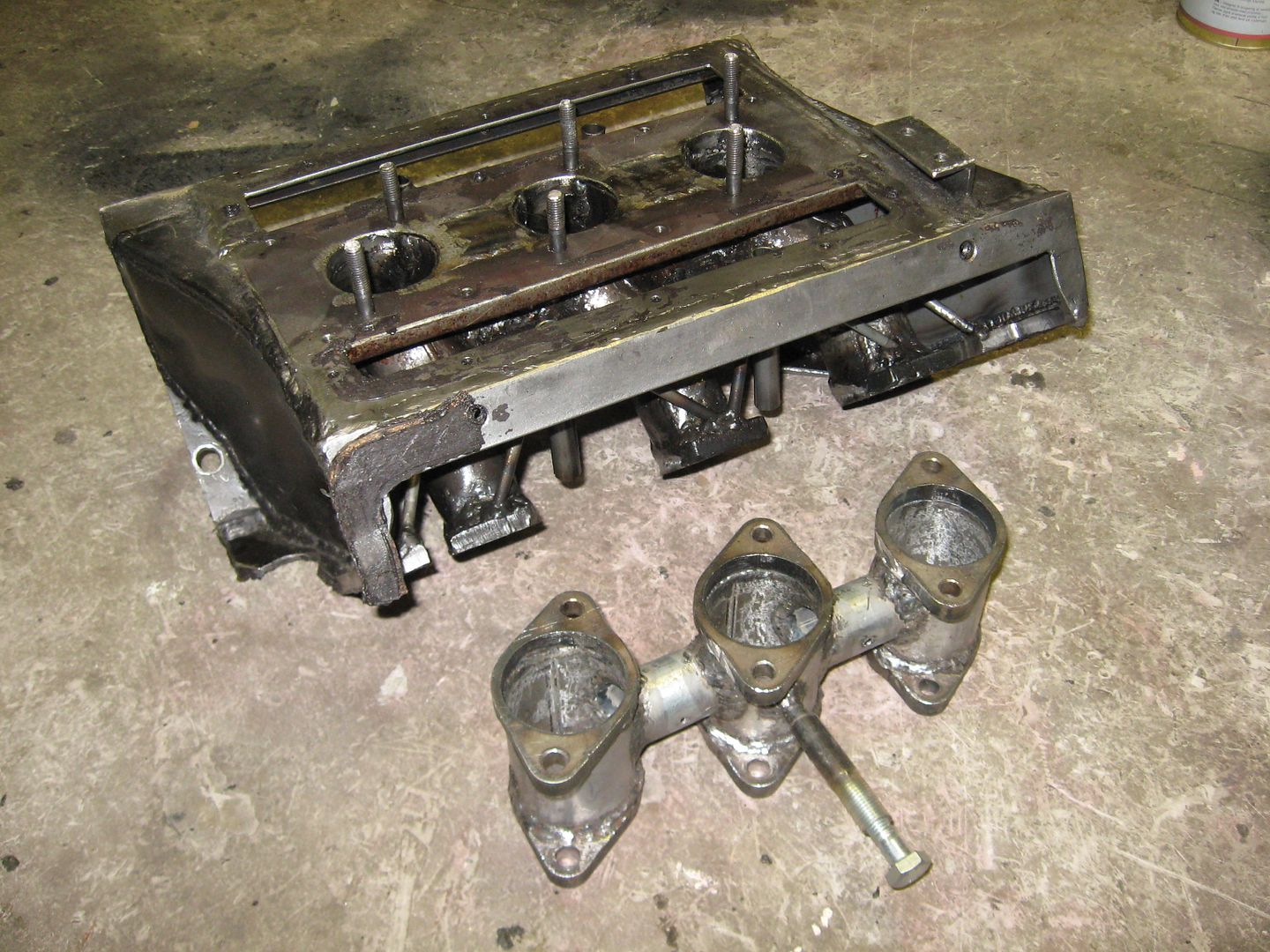

The stock 2.8 FI intake is a cross ram, so why not just build a bigger Mopar style?

Announcement

Collapse

No announcement yet.

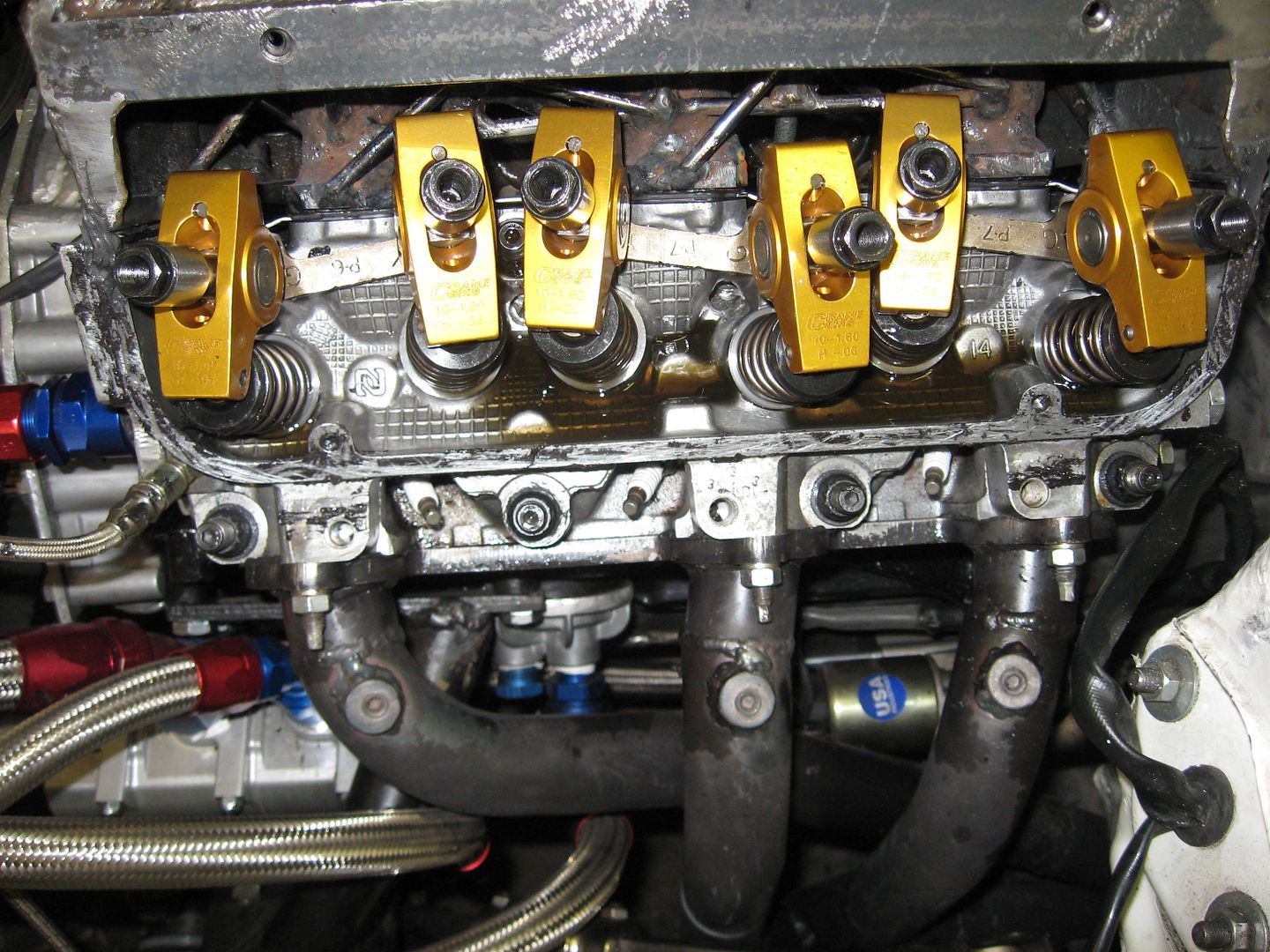

roller lifters with 2.8

Collapse

X

-

Man that is pretty damn good. Hey I've got a long shot for you. Have you ever seen the old Mopar cross ram? That put the carbs out past the valve covers. Which made room for very long runners and kept the carbs under the hood.

The stock 2.8 FI intake is a cross ram, so why not just build a bigger Mopar style?

-

Allright, time for todays results.

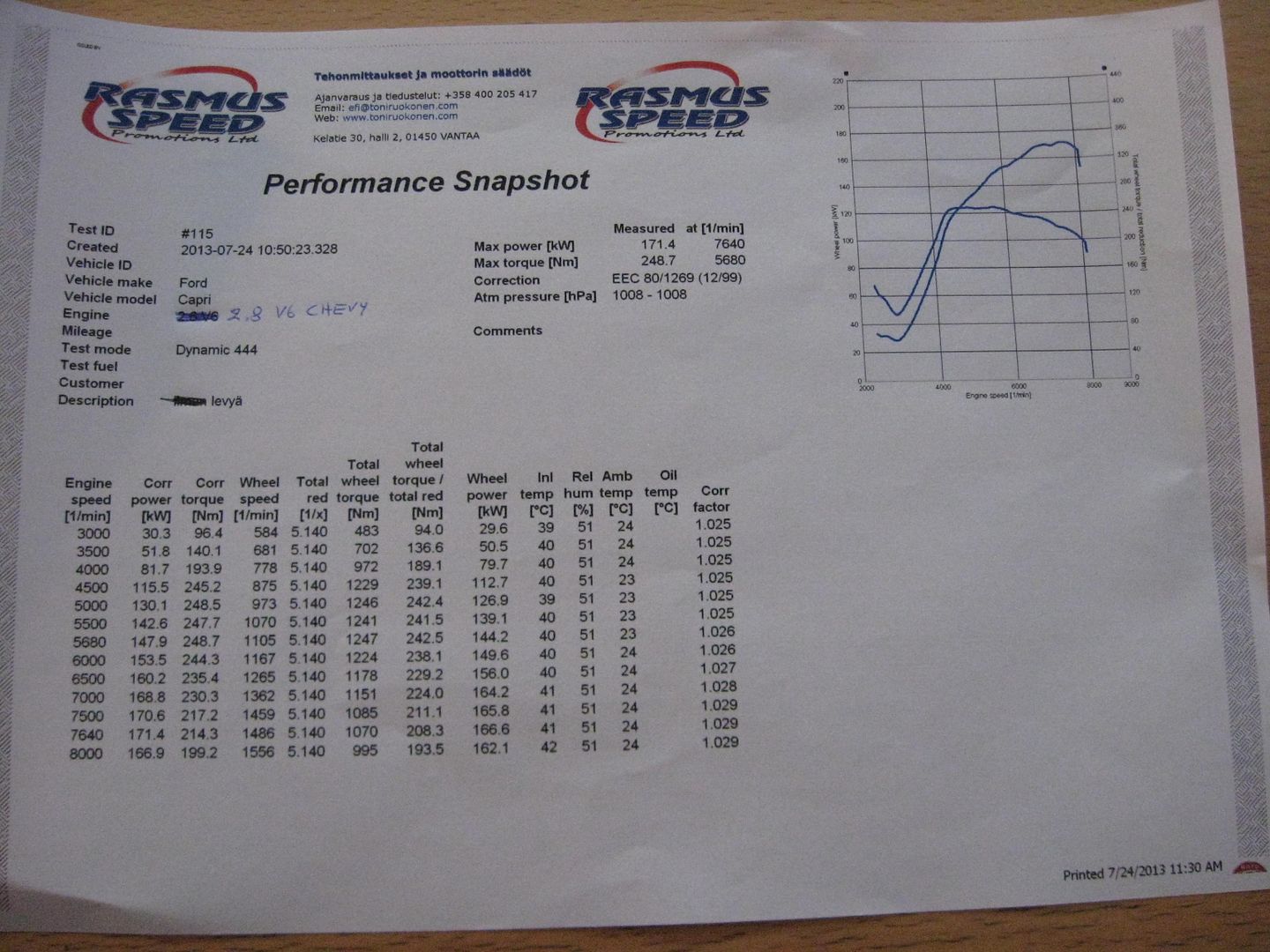

2.8 V6 engine with a Holley 390 cfm dp .

171.4 kW = 233 hp (back wheels) 7640 rpm , that is some 250 hp from engine.

248.7 Nm 5680 rpm

The hp number was 10 hp less without that plenum devider (so with open plenum),

not a very big difference.

This hp with a 4 bbl Holley carb was the same compared to a 3 bbl Porsche carb without the

extended intake.I did not mention earlier that the biggest so far hp number with the 3 bbl carb

was gained by a 4" extension.Some 20 hp was gained with longer runners.But I can not use the extension in my car because the carb comes

then out of the hood.

The conclusion of all this is , that the engine likes longer intake runners.

The longer the runners, the more hp.

Only problem is that you can not manifacture a carb V6 intake with long enough runners.

Intake for the 3 bbl carb and the extension

Leave a comment:

-

I put some update if someone is interested.

Dyno time is next week, wednesday 8.00 AM.

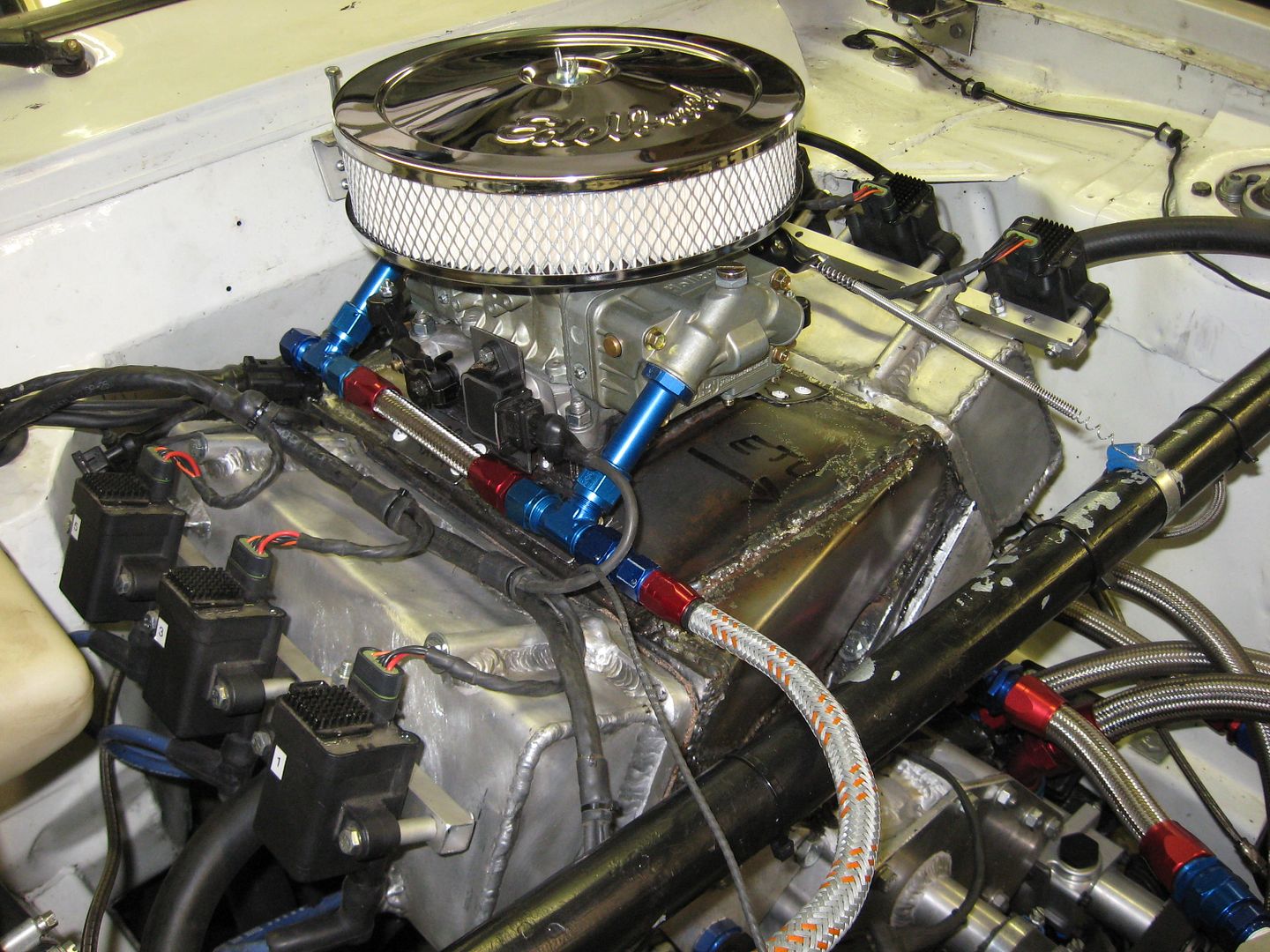

There is still some blue smoke , but it doesnt matter , we get to know if the new intake

for the douple pumper Holley 390 cfm is any good.

I need hp numbers better than with the 3 bbl Porcshe carb.

I bought an air filter for the Holley.

And there is an issue with the hood clearance.

The package is 1" too high, can not get the hood properly closed.

But that is the smallest issue right now.

You can see in the picture the position of TPS sensor,

it is in the primary throttle shaft

Leave a comment:

-

I suggest using bluing paper. It's paper that has ink in it that once compressed it bleeds out showing where you have contact on your surface area. I always use that stuff for situations like this to determine port alignment.

Leave a comment:

-

Okay, thanks for your advice.

Seems like my intake is like a banana,twisted to every direction.

I welded some more material to some of the runners.

And did a test with grease.

Now it seems relative nice.

I am going to do one more test without any sealant to the runners to

see if there is a leak or not.

And if you look closely , you can see the welded intake runner (the middle one),

that has 1 mm steel welded to the gasket surface.

I can not put a feeler gauge between the gasket and the runner surface.

Last edited by veekuusi; 07-14-2013, 07:57 AM.

Last edited by veekuusi; 07-14-2013, 07:57 AM.

Leave a comment:

-

You should consider trying the gaskets that use a plastic frame to hold the gaskets in place instead of the metal frames. The metal (or plastic) has no part in the sealing, it just holds the seals in the right position. It is much easier to shear the gasket off the metal plates than it is to shear it off the plastic ones. Looks like it can't hurt trying, the metal ones seem to be bad actors for youre application. Larry

Leave a comment:

-

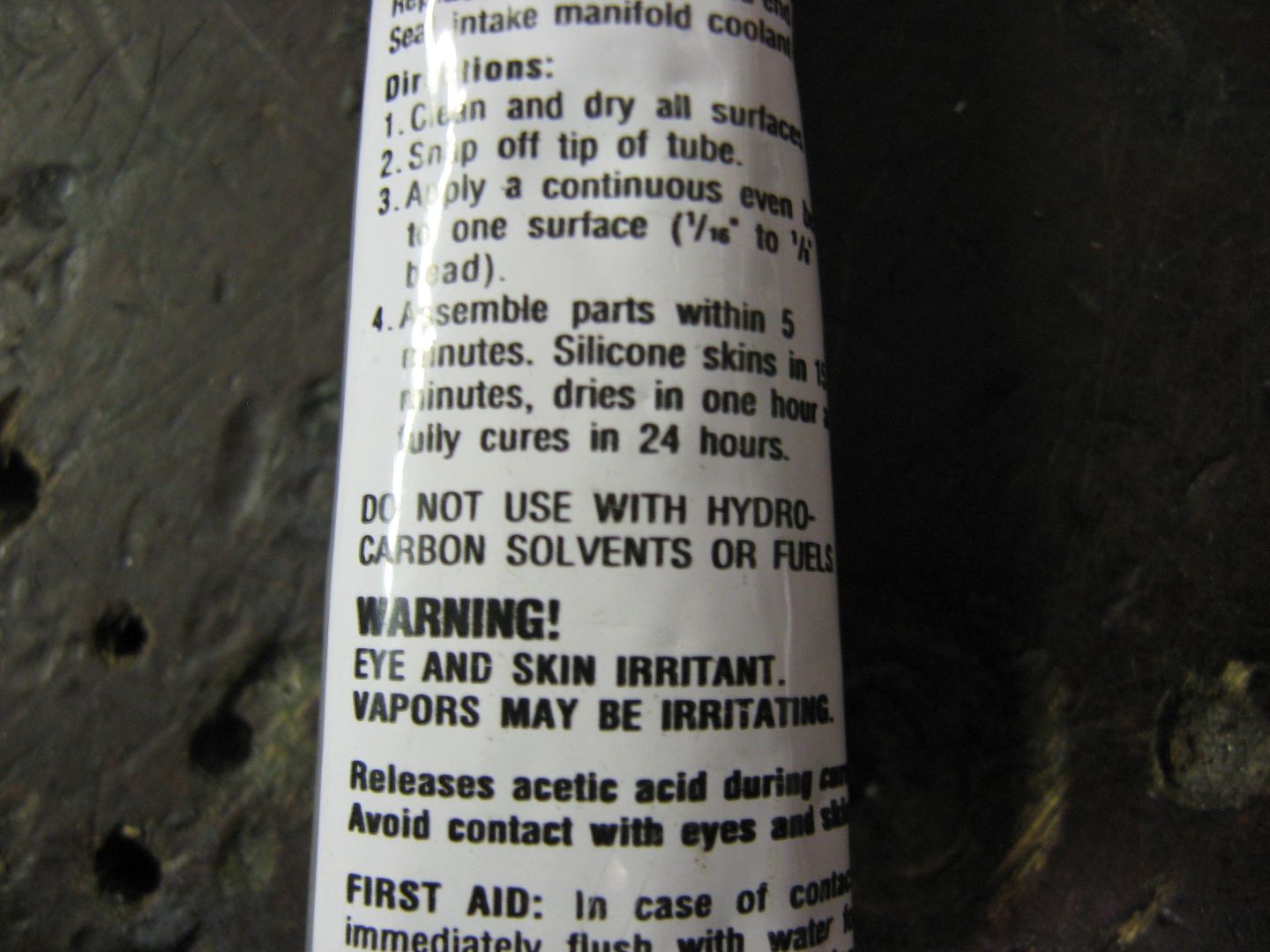

You need to use Permatex #3, it's the only one made for fuel.

Leave a comment:

-

It is hard to find a RTV-sealant that can take fuel.

It says in all the intructions of use "not to use with fuel".

I did a test with Wurth RTV. After 2 hours in fuel, you can scrape the sealant away.

Next week a have in my hands "the best" RTV, Kent Sili Gasket 2.

According by it`s manufacturer, it can take fuel.

So far I have put the RTV only to water passages, now I try to seal the runners with sealant.

I found that it is no use over tighten the manifold bolts.

There was damage to the rubber seals, not good.

Leave a comment:

-

I put a new set of gaskets to this new intake.Originally posted by Superdave View PostI'd put a bright flashlight in the galley, bolt the intake back down and then use that snake camera to peak around and see if you can figure out where the leak is...

are you re-using the intake gaskets every time?

I have used the new ones 3 times in a week, because I have had to take the intake out because of the leak

every other day.

No visual damage can be seen in gaskets.

I think the rubber part will flatten if the intake is bolted lets say something like 2 weeks or more.

Leave a comment:

-

I'd put a bright flashlight in the galley, bolt the intake back down and then use that snake camera to peak around and see if you can figure out where the leak is...

are you re-using the intake gaskets every time?

Leave a comment:

-

Is the intake possibly siding down too far and misaligning the ports which then causes the leak?

Leave a comment:

-

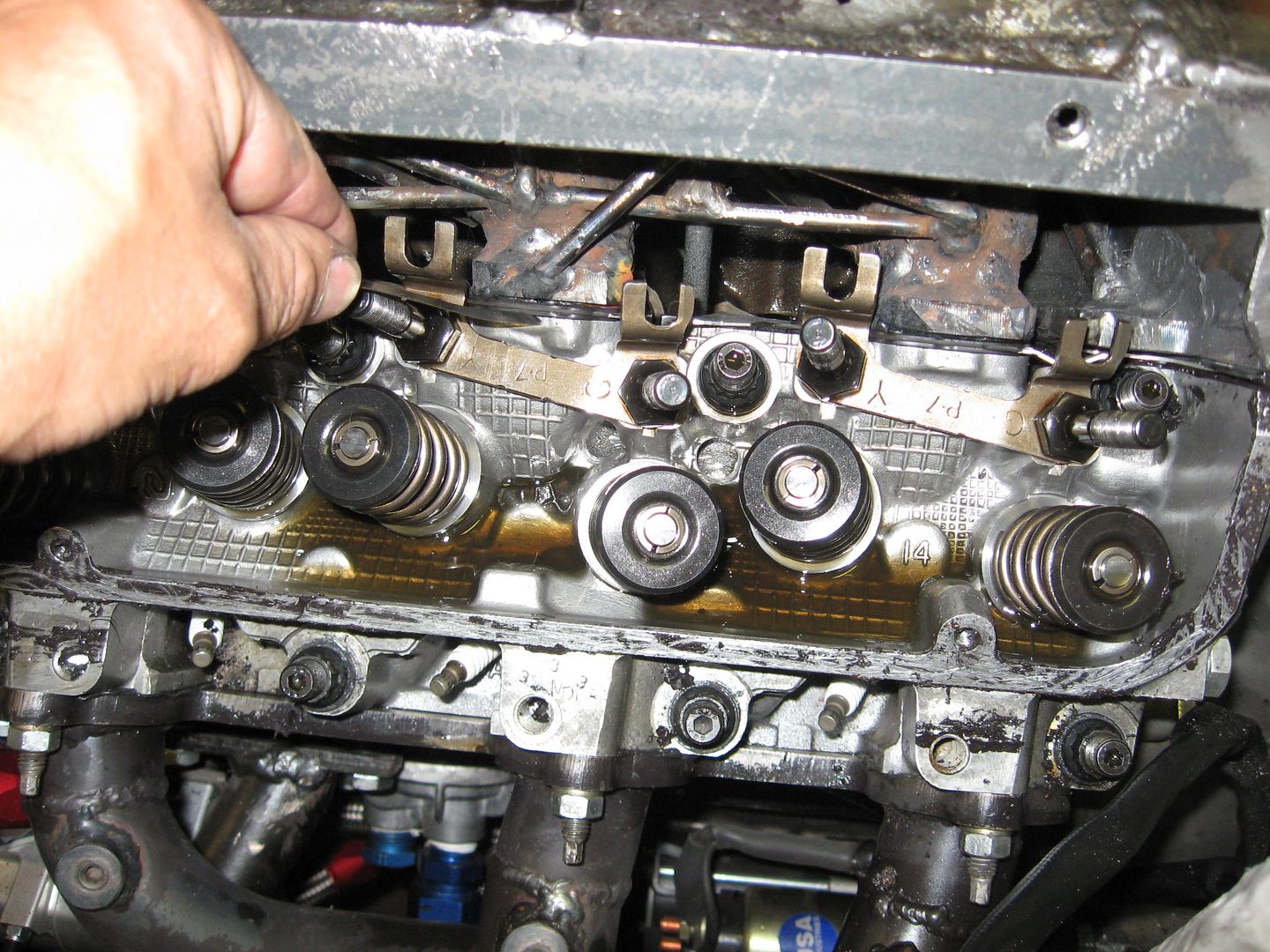

I am still having trouble with the intake.

My manifold gaskets is sucking oil in from the valley.

Blue smoke coming out of the engine.

I point here with my finger where I think the leak is.

It is the lowest section of every runner.

It seems that when I tighten the middle manifold bolts, it turns the runners so that the gasket can not hold.

I welded some more supports to the manifold , but no help what so ever.

And thats not all.

When I start the engine, you can hear "klonk klonk".

One tooth is missing from the flywheel ring gear.

Leave a comment:

Leave a comment: