Announcement

Collapse

No announcement yet.

roller lifters with 2.8

Collapse

X

-

Wee bit difference, huh? LolOriginally posted by ericjon262 View PostRocker studs, not main studs.

Sent from my HTC One X using Tapatalk 2

Leave a comment:

-

Originally posted by pocket-rocket View PostYou could always use a windage tray from a DOHC or 3x00. Drops right in but it probably won't be as strong as a true stud girdle.

Sent from my HTC One X using Tapatalk 2

Rocker studs, not main studs.

Leave a comment:

-

You could always use a windage tray from a DOHC or 3x00. Drops right in but it probably won't be as strong as a true stud girdle.

Sent from my HTC One X using Tapatalk 2

Leave a comment:

-

I decided to start the engine without stud girdle.Originally posted by ericjon262 View Postdid you stud girdle fit? i never saw pictures of it.

I have not forgotten it , but hope the engine will survive first run without it.

Most important is to get the engine running.

I have more time and money for it coming winter.

Leave a comment:

-

Possibility to measure exhaust gas temperature in dyno session.

1/8 NPT thread

Leave a comment:

-

This is a one year anniversary post to this thread.

One year and a week ago my friend suggested to install a

60 degree chevrolet engine to my race car.Because I had trouble with the old Ford engine.

He had seen a pair of 3400 heads , and realized the potential.

I had never ever seen a 60 degree chevy engine.

I googled and searched for information about this 60 degree engine.

I found this 60degree web page.

Asked some silly questions.

You guys helped me .

I did not have the change to carry on all your suggestions,

bacause of money and time.

But I am satisfied with your help, thanks.

Without internet , it would have been impossible to gain so much knowledge

about this engine in one year.

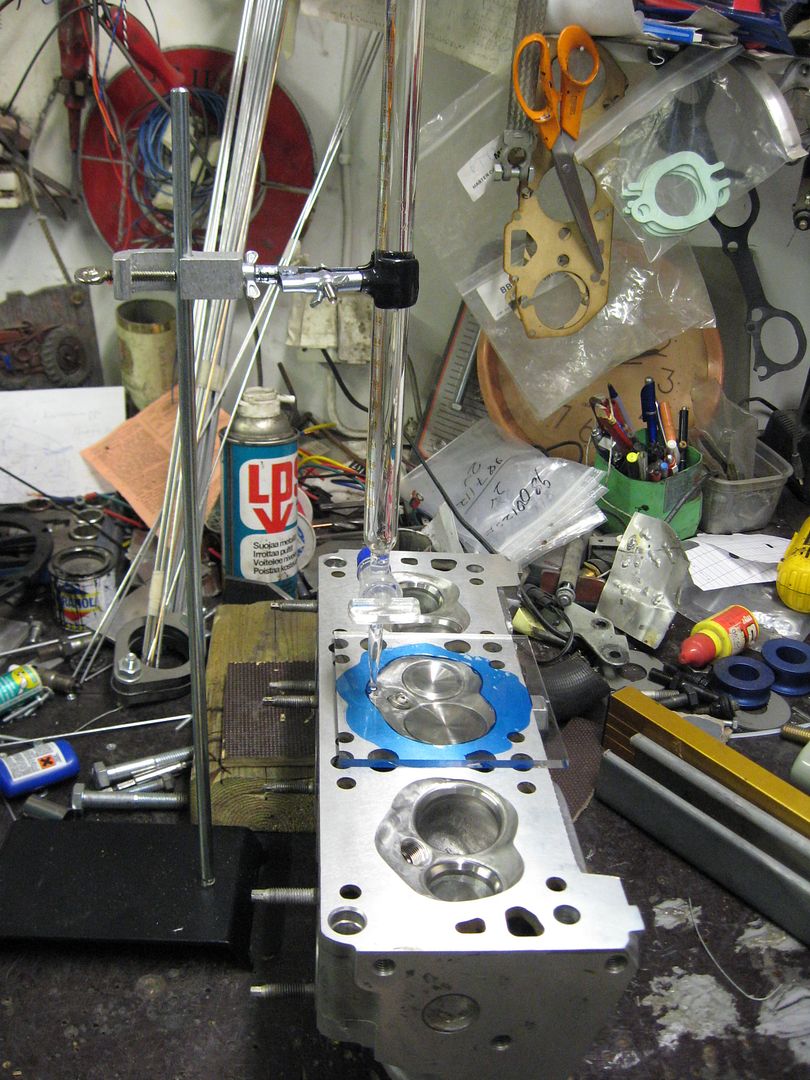

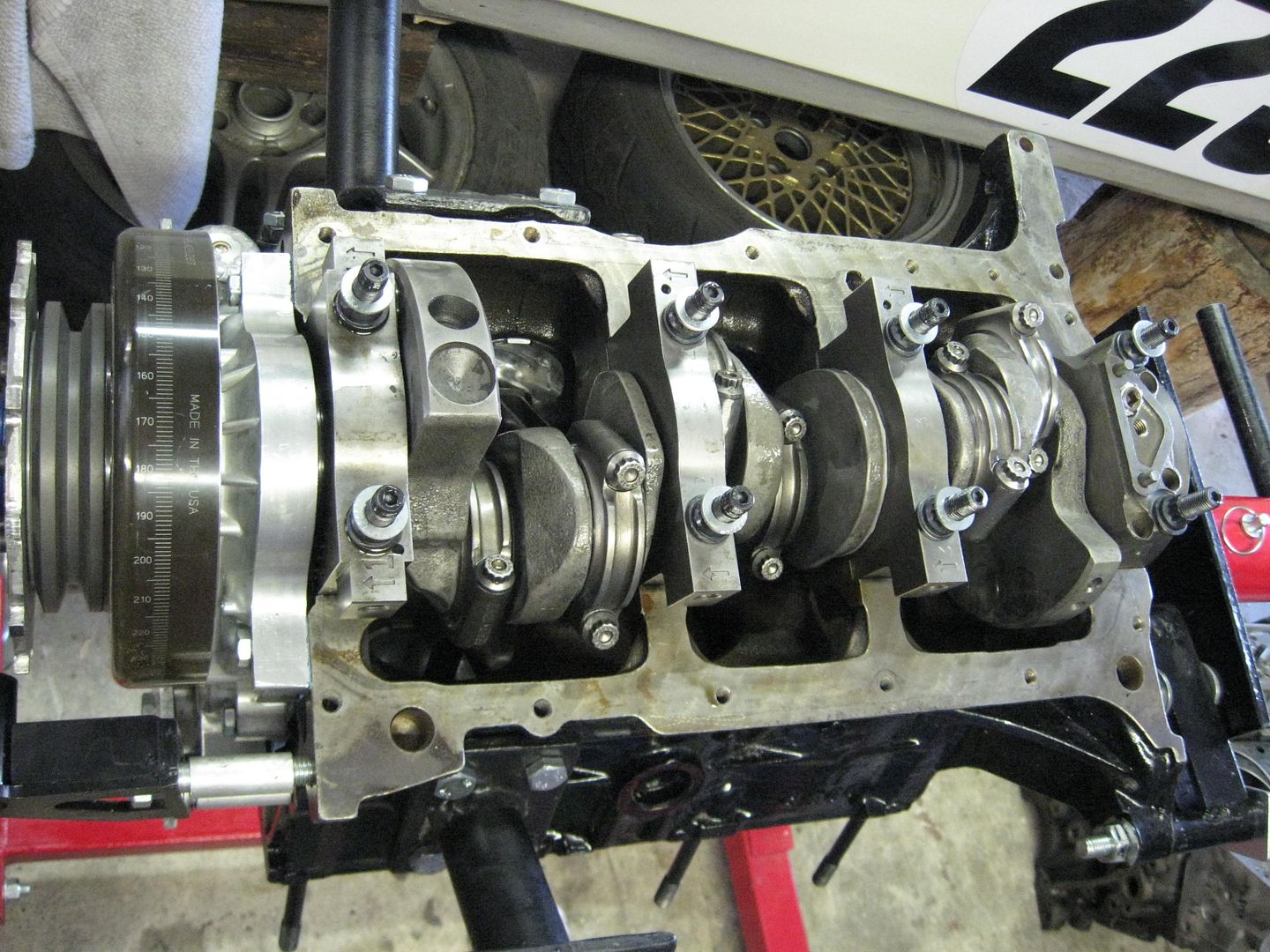

The compression ratio , engine 2850 cc :

-stock 3400 head 28 cc , my modified 32cc

-head gasket 0.040 hole 3.620"

-bore 89.25 mm 3.5140"

-stroke 76 mm 2.990"

-piston zero deck height,flat top

-piston valve reliefs 4 or 5 cc (it was difficult to measure)

With 4 cc valve relief 12.11 and

with 5 cc valve reliefs 11.86 compression ratio.

I would consider 12:1 to be the best for my application.

Leave a comment:

-

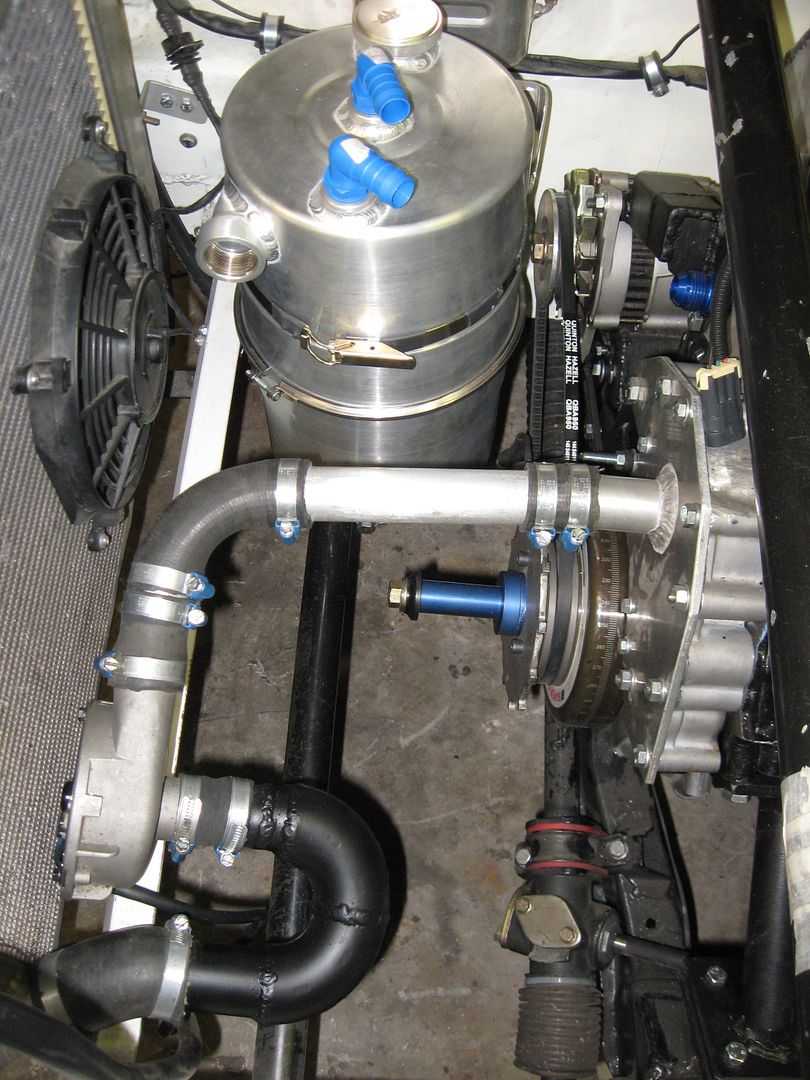

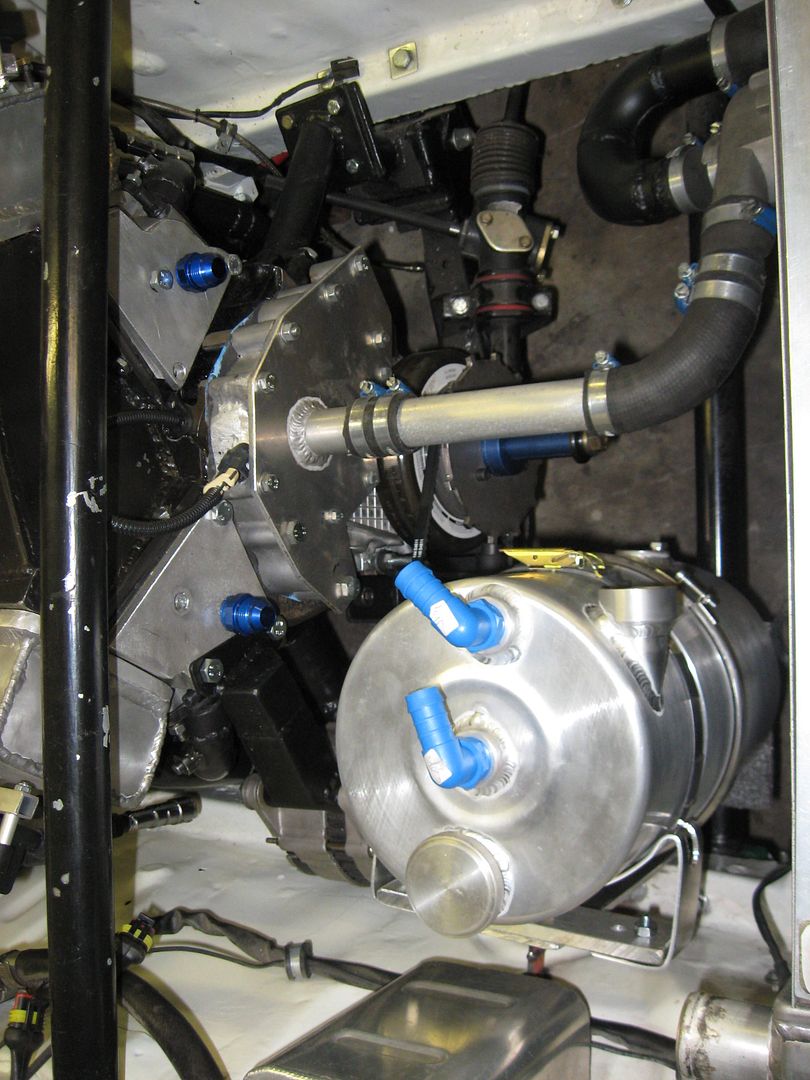

Summer vacation goes on (1,5 weeks still to go) , so pretty much time to spend in garage.

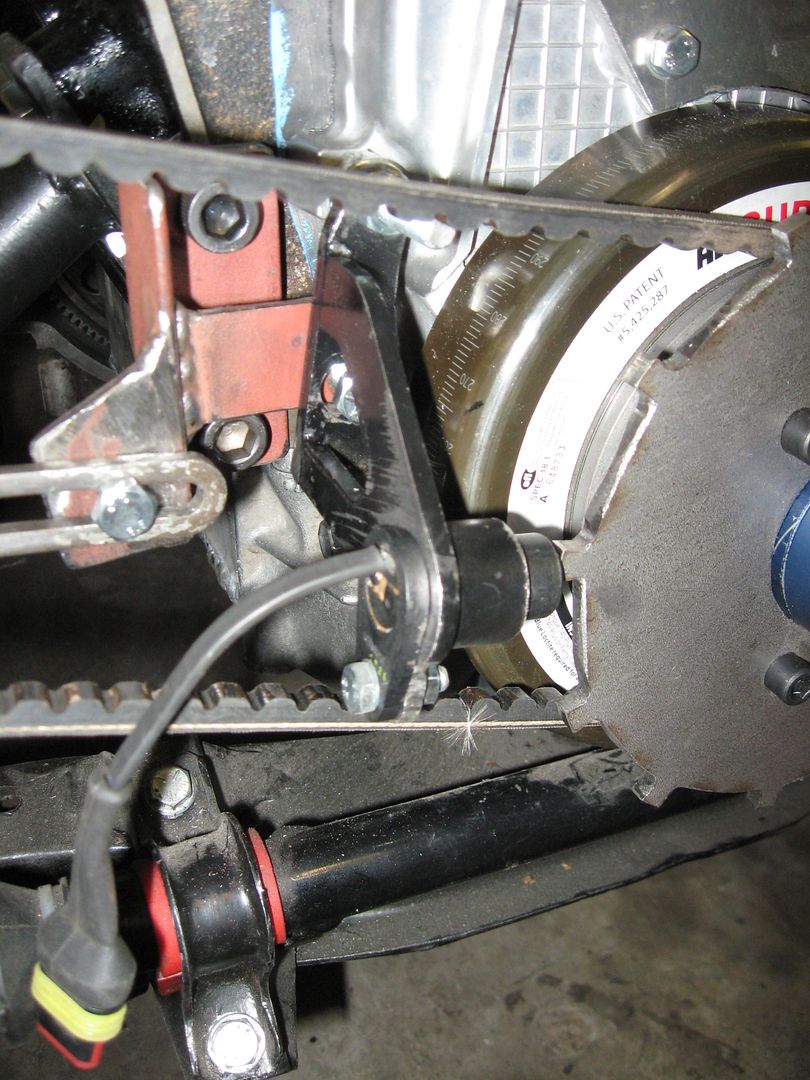

Had to do new brackets to alternator and hall sensor.

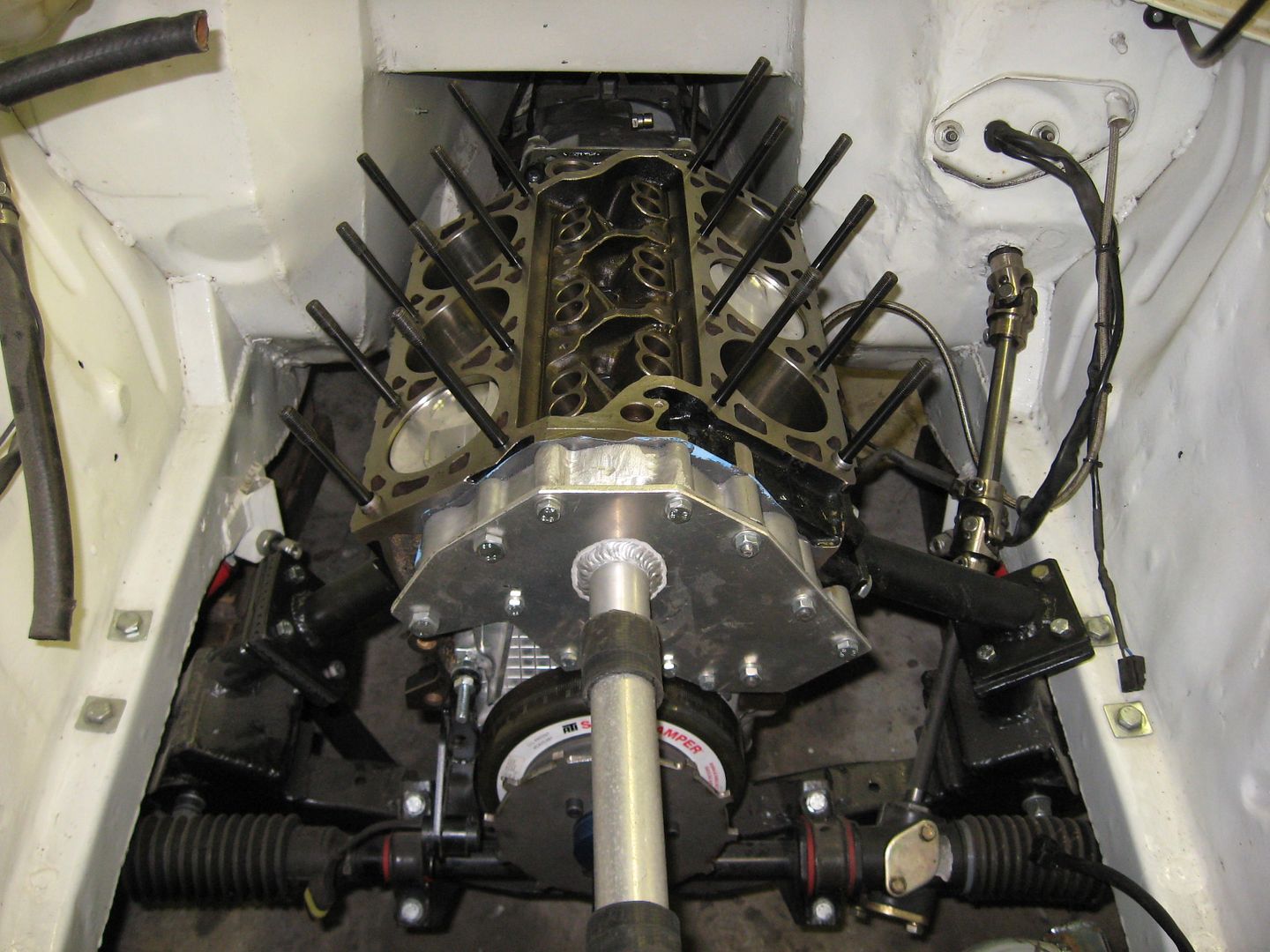

When I lifted the engine to the car ,

the engine bracket touched the alternator.

4 weeks to the last race of this season.

I try to be there.

As almost all you know, this project is some half a year late.

Still much work to do, I been waiting a dry sump pump now for 2 weeks.

Hope it shows this week.

Leave a comment:

-

Originally posted by unchained01 View Postwow nice progress !!!

Sent from my HTC One X using Tapatalk 2

Leave a comment:

-

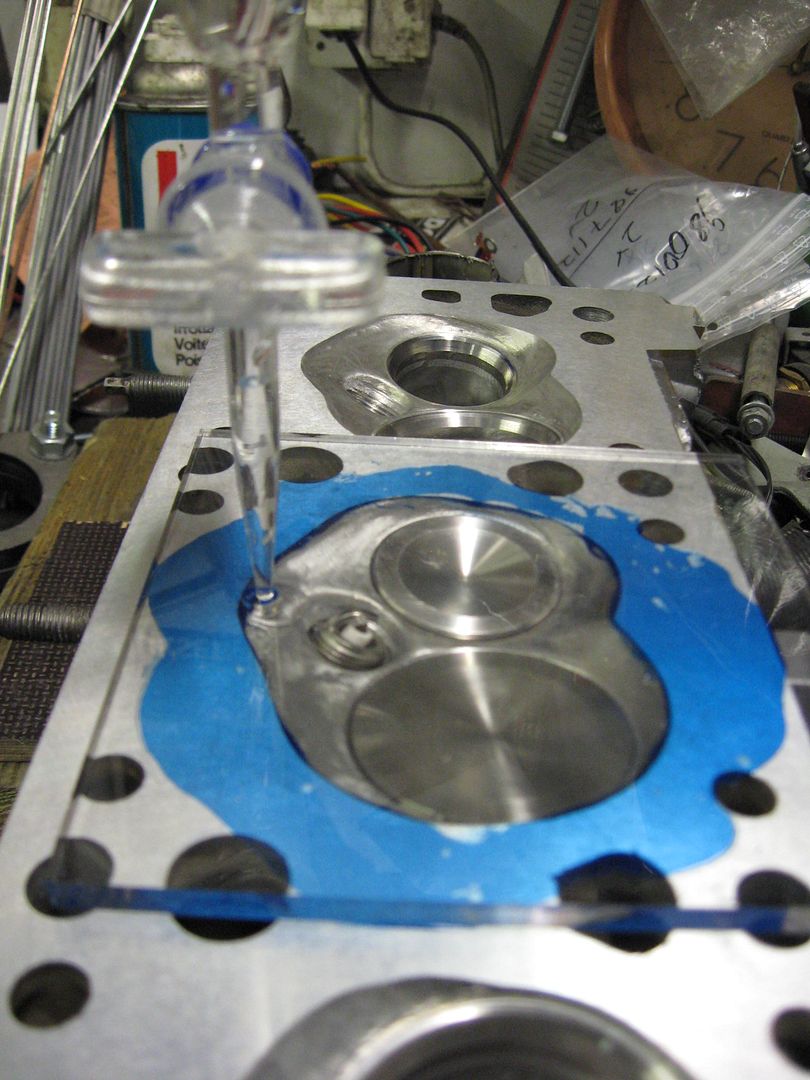

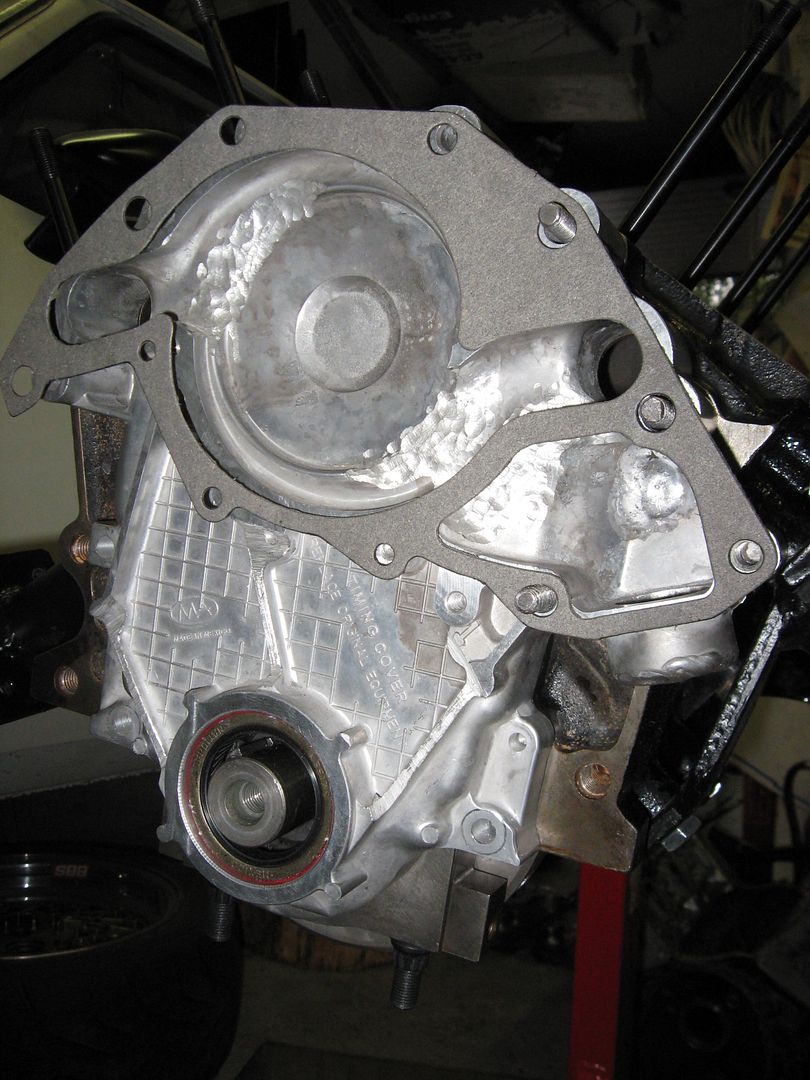

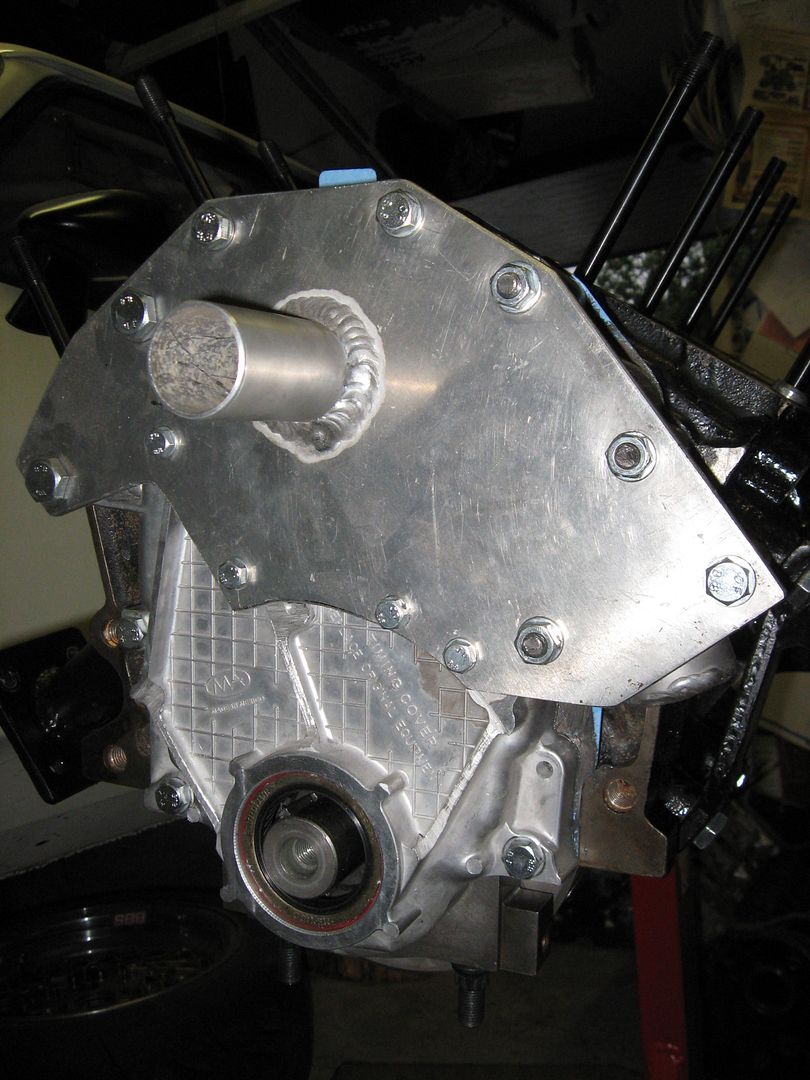

I put pretty much RTV silicon, because I want to be sure that oil is going

to be inside of the engine. Maybe that is overkill, but had trouble with my

old Ford engine. Oil was all over the place, except inside of the engine.

Leave a comment:

-

I was curious and did the math.

Lift.....Intake.....Exhaust.....WT Intake.....WT Exhaust

.040.....21.4.....18.2

.079.....43.9.....36.7

.118.....61.2.....55.5

.157.....78.4.....68.4

.196.....99.2.....92.....(.200)..116.7.....112.6

.236.....120.6....112.7

.276.....141.8....125..

.315.....156.8....135.8

.354.....174.4....142.2.....(.350)..187.3.....158. 4

.393.....187.3....148.8

.433.....196.4....151.7

.472.....202.2....154.7

.512.....206.4....155.1

.551.....209.8....156.4.....(.550)..235.8.....178. 8

Leave a comment:

-

I am not going to act like an expert in this flow bench case, bacause I am not an expert.Originally posted by NateD4 View PostI presume the .58 LPS number is the BSFC for the engine? So the 337 HP is pretty close to what actual is?

Or is the 337 HP based on airflow estimates without efficiency losses taken into account?

But I think the LPS number is calculated with effiency lossen taken into count.

Because it says corr. LPS.

It would be nice if some one could correlate these flow numbers with WOT TECH flow numbers.

I found this in the internet:

cfm x 0.257 x number of cylinders

236 x 0.257 x 6 = 364 hp

And I want to say that , the porting was done by amators (me and my friend).

But the flow bench test was done by pro, the best here in Finland.

With the best equipment available.

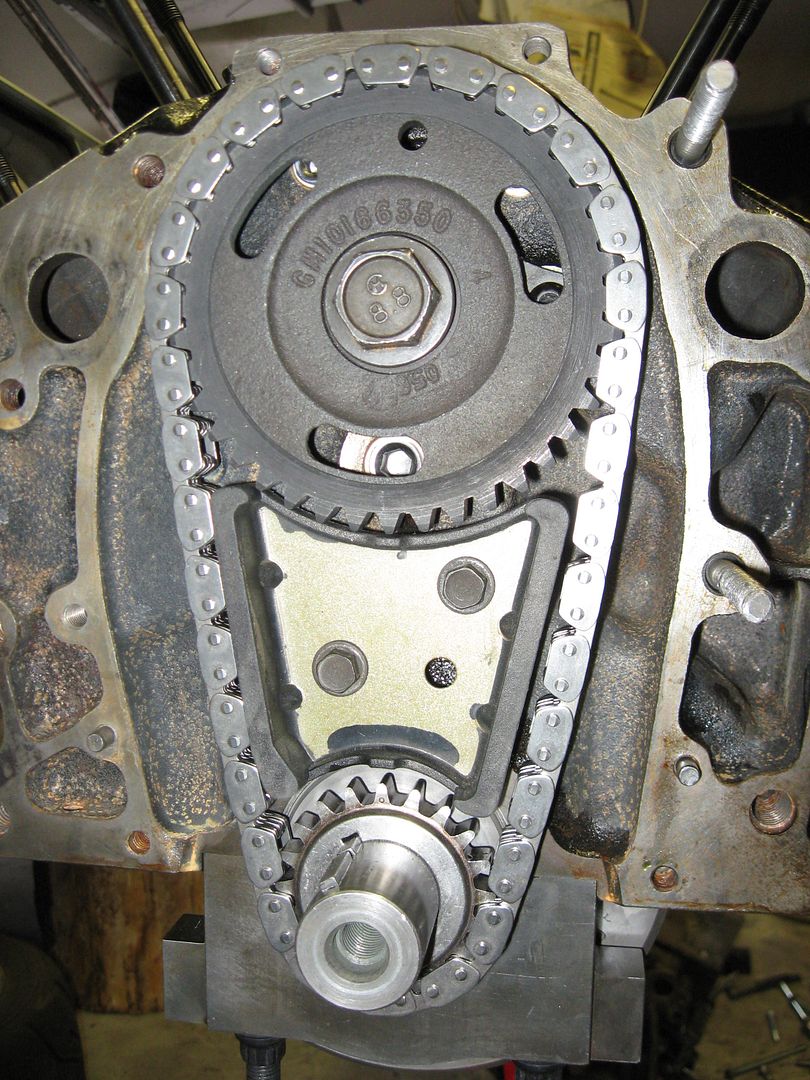

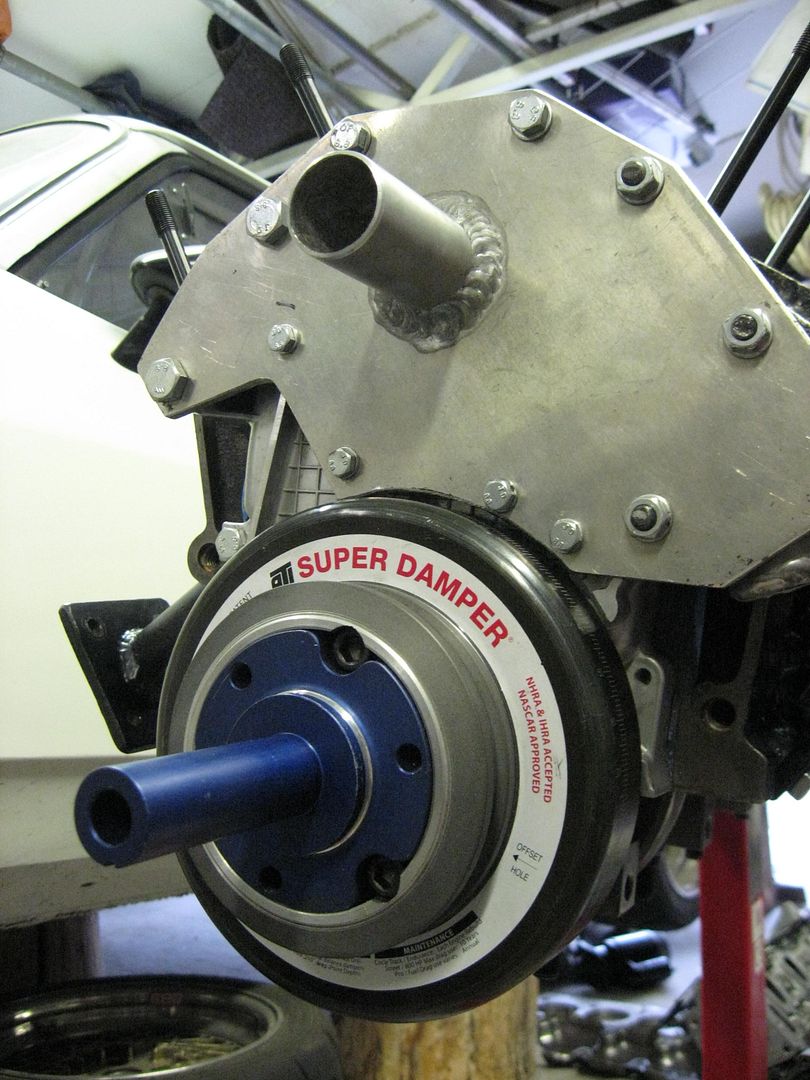

Pictures from today morning:

Last edited by veekuusi; 08-07-2012, 12:35 PM.

Last edited by veekuusi; 08-07-2012, 12:35 PM.

Leave a comment:

Leave a comment: