Announcement

Collapse

No announcement yet.

roller lifters with 2.8

Collapse

X

-

looks like you may have stretched the mains a little bit. I know its probably too late to ask, but any indication of cap walk? Any distortion with the mains with the heads torqued on?

-

Ouch, that is nasty! So are you going to put the 2.8 crank in the 3.1?

Leave a comment:

-

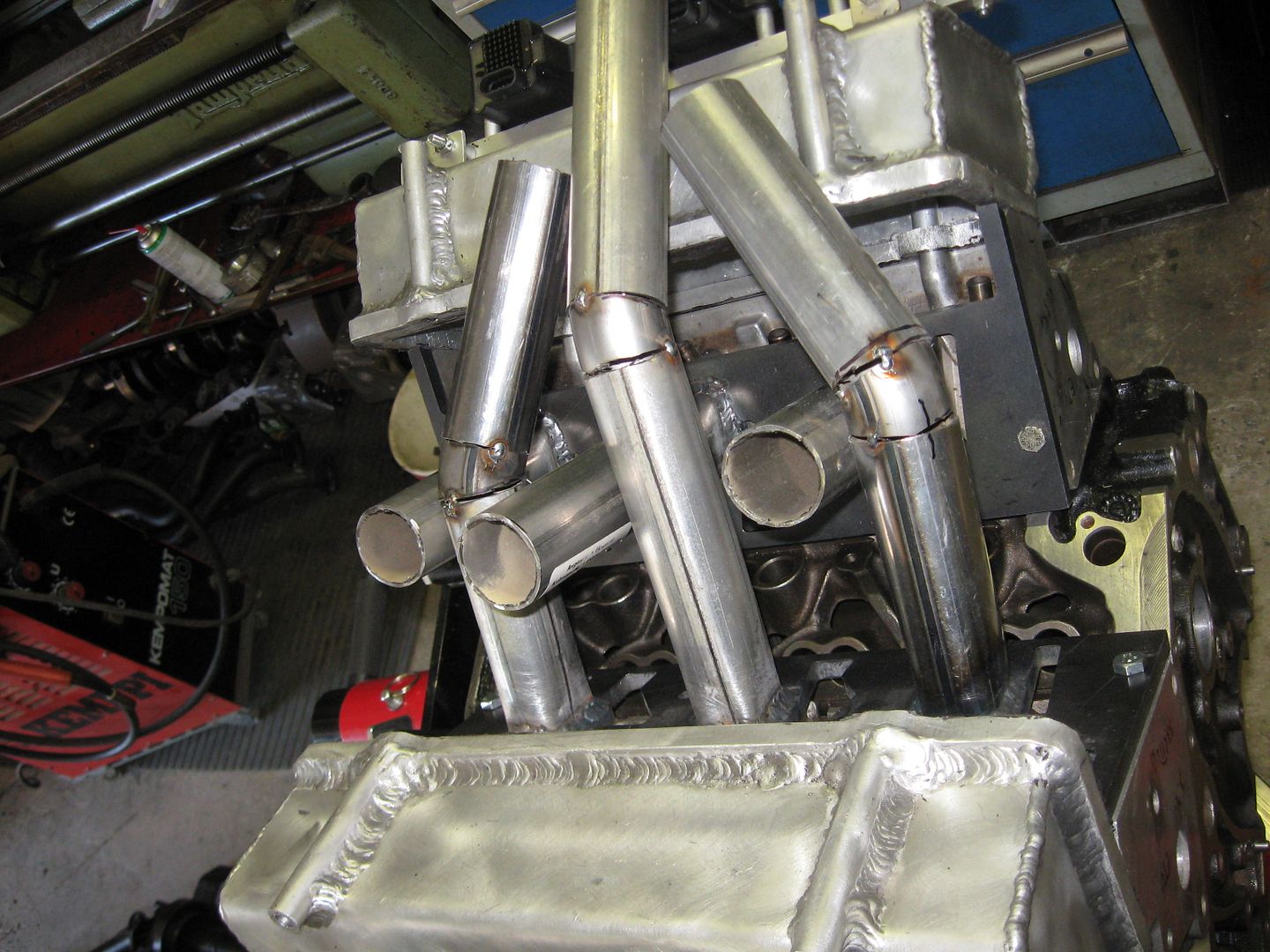

I started to make the new crossram intake.

Tube ID 42 mm (1.65").

Runner lenght from valve to the plenum 400 mm (15.7").

Leave a comment:

-

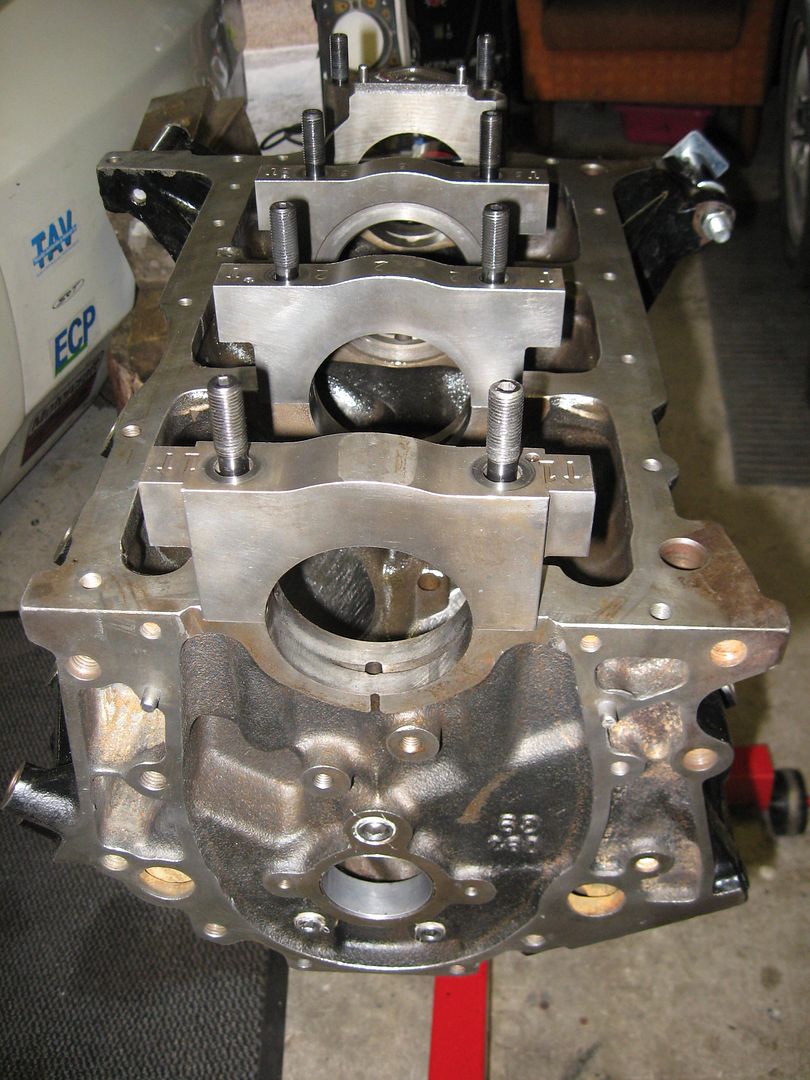

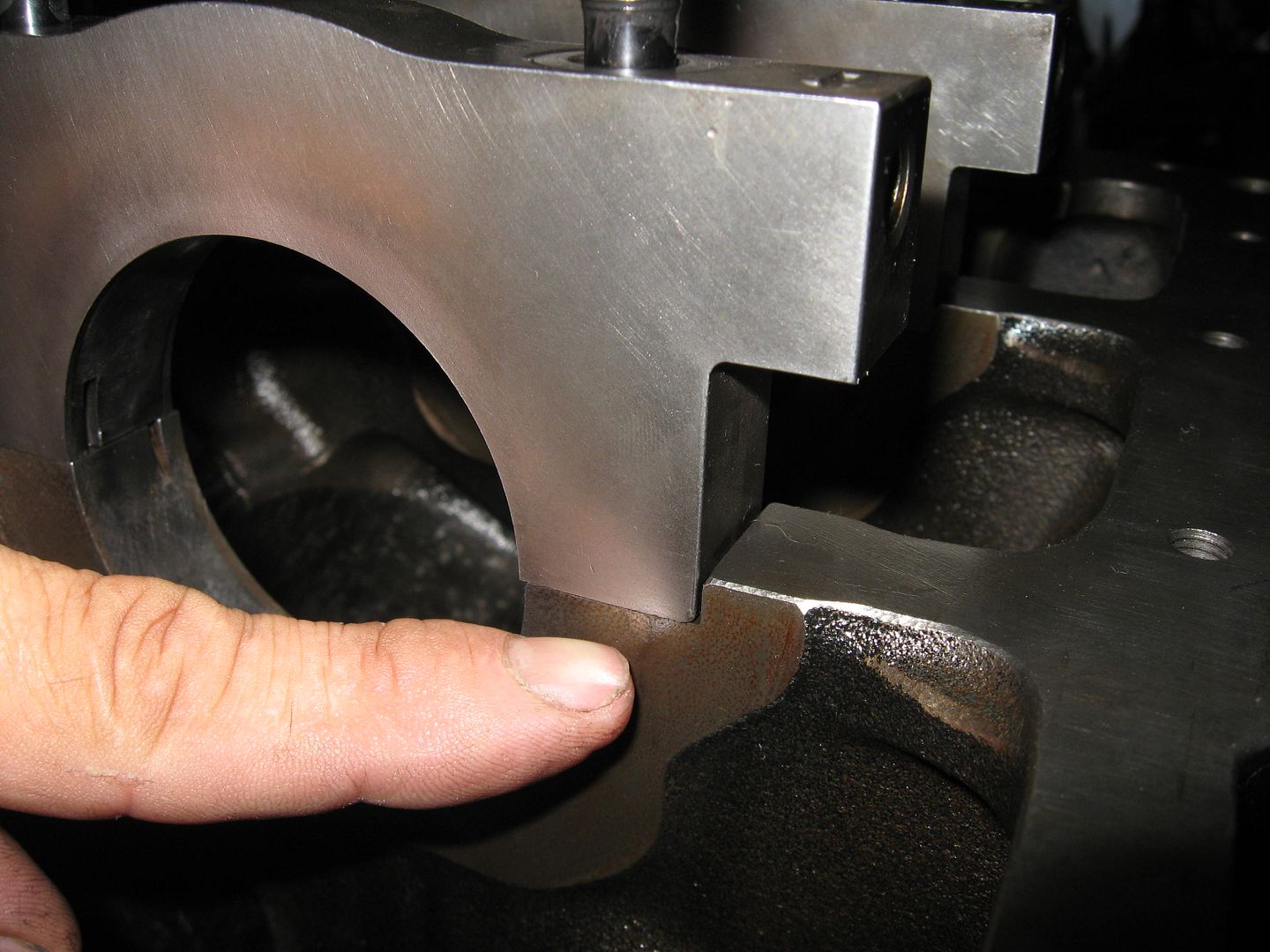

The crank does not turn when the main caps are bolted.Originally posted by trotterlg View PostI really canno't see how this could happen. If you bolt up that main with a bearing in it does the crank turn OK? This problem does not make any sence to me at all, there is nothing to break or wear that would cause this. I am thinking it must have always been this way. If you need it fixed, I would just build up the side of the cap, mill it down a little and then have it line bored and be happy. Larry

The issue is with the caps not with the block.

But there is no possibility to get only new caps to the engine.

I have to buy a new engine (3.1 V6) , more specifically I have to buy a complete car, because no bare engines are

available here.

In a matter of fact, next week a get a 1996 Chevrolet Lumina to my property for some $ 400 .

I take the engine out of it and leave the rest for junk yard.

There are also some scratches in the block.

That is why a new block is needed.

Leave a comment:

-

I really canno't see how this could happen. If you bolt up that main with a bearing in it does the crank turn OK? This problem does not make any sence to me at all, there is nothing to break or wear that would cause this. I am thinking it must have always been this way. If you need it fixed, I would just build up the side of the cap, mill it down a little and then have it line bored and be happy. Larry

Leave a comment:

-

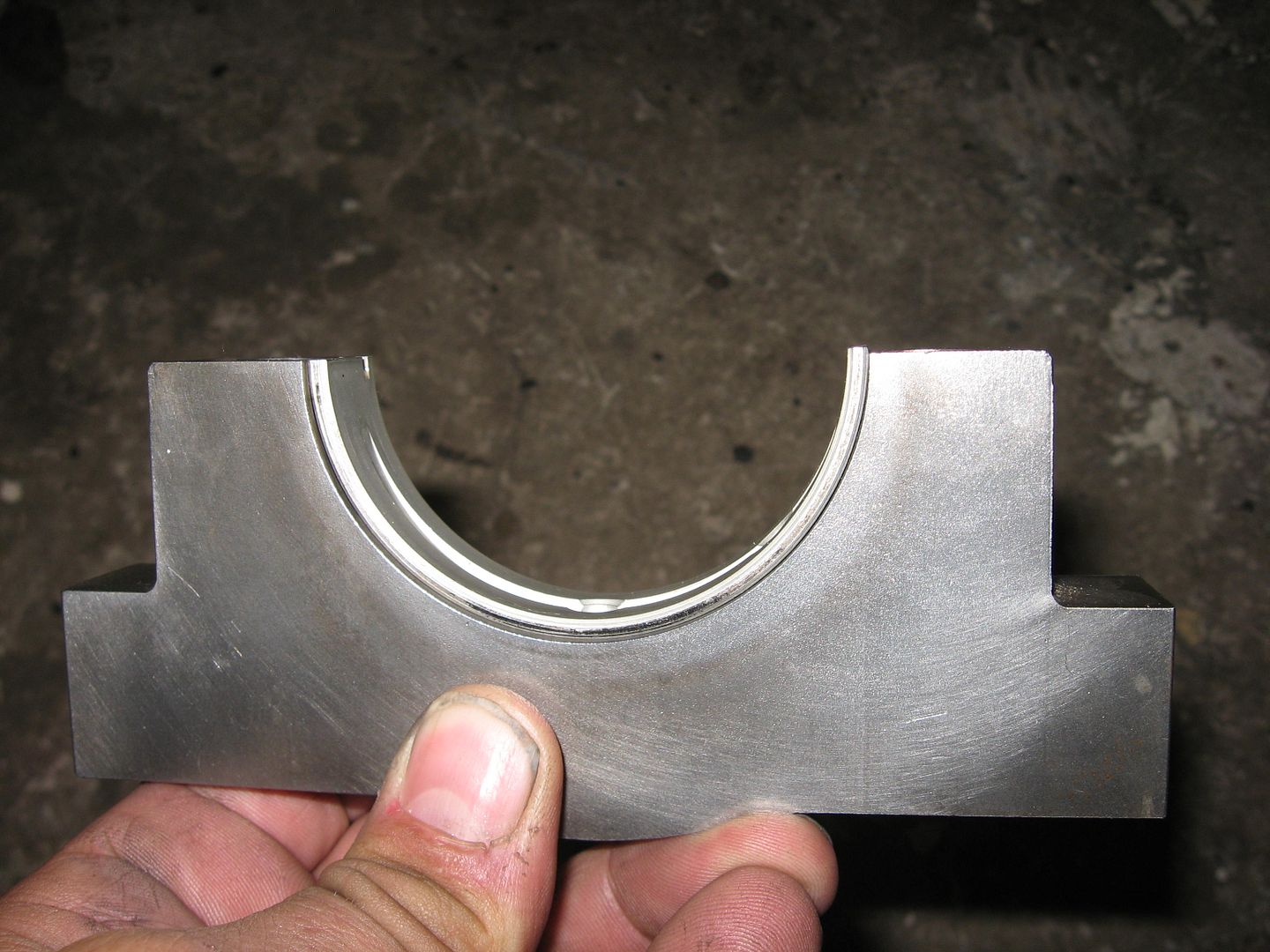

Are you sure it isn't the cap itself that's damaged?Originally posted by veekuusi View PostEdit:

Just found a new issue.

#2 main cap has 1 mm side play to the block.

That is not good news.

I think I need a new block.

It sucks that this happened but on the bright side at least you know exactly what the problem was so you know what to avoid the next time around.

Leave a comment:

-

Well that's a lot better than I expected. I thought your rods would have taken a good beating at 7k and no oil. That's good news in my book for that kind of problemOriginally posted by veekuusi View PostNo other damage was found than that.

Camshaft , heads , lifters and other, no damage.

Leave a comment:

-

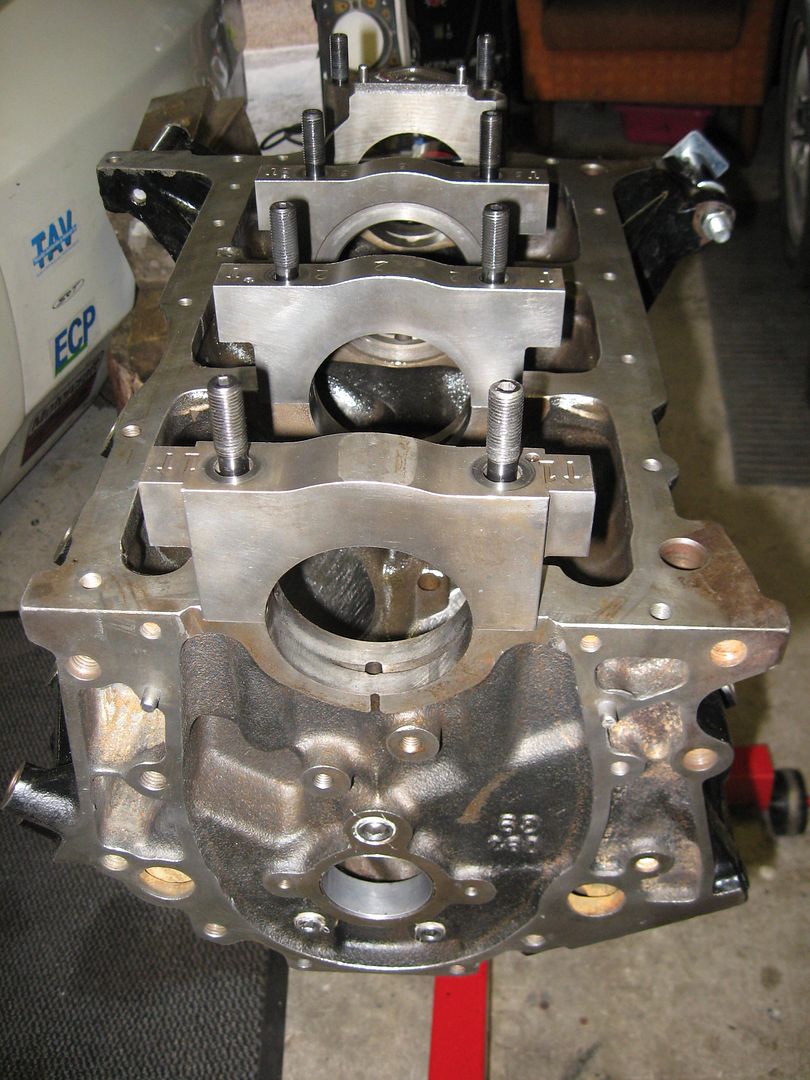

Here we go again.

Just got the crank back from the machine shop.

Main journals are now .010" and connecting rod bearings stayed standard size.

I found both the mains and connecting rod bearings in the nearby speed shop.

The connecting rod big ends were also checked for roundness.

The block still needs main line honed,because of the heat .

There was colour change in some of the main caps (blue), that is an indication of material extension.

No other damage was found than that.

Camshaft , heads , lifters and other, no damage.

Edit:

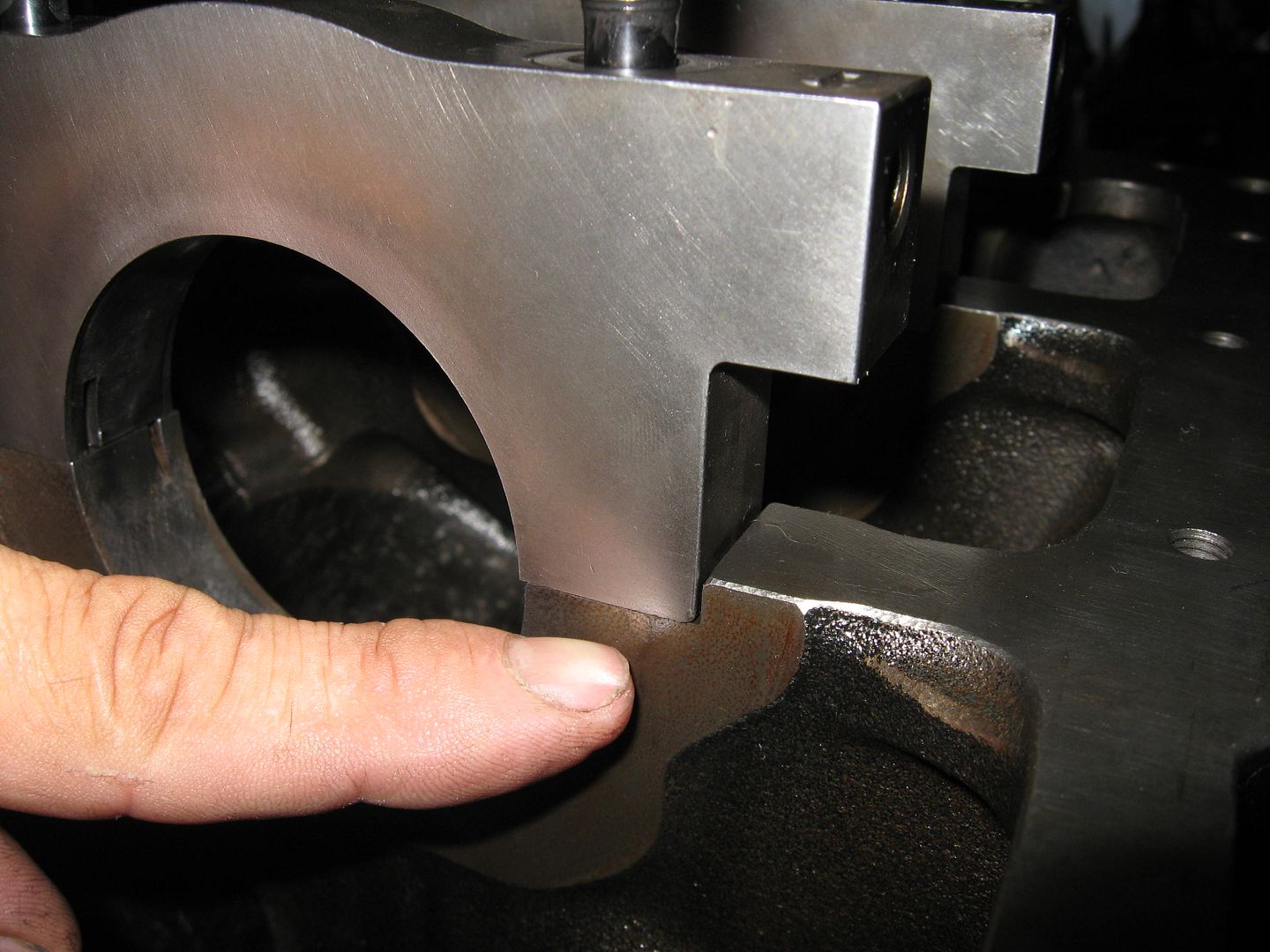

Just found a new issue.

#2 main cap has 1 mm side play to the block.

That is not good news.

I think I need a new block.

Last edited by veekuusi; 08-17-2013, 12:20 AM.

Last edited by veekuusi; 08-17-2013, 12:20 AM.

Leave a comment:

-

Bummer, hope the cam is OK. You may take advantage to go with an internal balanced crank, that may help you a little. Just amazing how little things just sneak up on you and make a mess. Hope you can get it back up and running again soon. Larry

Leave a comment:

-

Originally posted by Purple pit View PostDamn, that was some bad news! I had a great time watching the videos of this car racing. I was looking forward to new videos.

Leave a comment:

-

Damn, that was some bad news! I had a great time watching the videos of this car racing. I was looking forward to new videos.

Leave a comment:

-

No oil pressure at all.Originally posted by ForcedFirebird View PostOh no!

Low oil pressure?

There was 11 litres (some 3 gal)of oil in the engine, but it was in the wrong place, it

was in the oil pan (in the engine) , not in the dry sump tank (it was empty).

The dry sump oil pump did not get the oil from the engine, because the pre filters were blocked.

RTV silicon mostly.

My mistake.

I should have checked the filters.

I pulled the intake too many times, bits and pieces of RTV went to the engine every time,

although I tried to be careful not to drop them inside.

There is also bad design in the filters, they are in a kind of "tube", once the carbage gets in the

filter area, it do not come out very easy.

The filter area has to be modified.

And IF I continue racing in the future, one thing is the most important.

BIGGER OIL PRESSURE LIGHT!

Last edited by veekuusi; 08-09-2013, 11:56 PM.

Last edited by veekuusi; 08-09-2013, 11:56 PM.

Leave a comment:

Leave a comment: