Wow interesting build and long thread.

There is no issue using two washers with the ARP studs, as long as the washers are ARP washers. ARP uses the same material for their washers ass their bolts they harden and flat grind them. If you use a non hardened washer you may see some deformation of the washer.

I heard about the ARP issue and decided to get custom studs made instead that fit the block. Its probably easiest to just do what you did or pay ARP for custom studs.

Out of curiosity the main bearing cap that was discoloured, how did it read dimensionally? Was it out of round at all when torqued in place?

Do you think you can break 300 HP without more RPM? Great build btw!

Announcement

Collapse

No announcement yet.

roller lifters with 2.8

Collapse

X

-

That is also the only stud option that they sell that fits our setup without going into asking them to design a new bolt length/thread combo. Trust me I think Ben has looked through it many of times trying to get the right length since he was the one that sourced these bolts. They are not "kits" they are simply chosen bolt lengths that work with washers. If your that concerned go find some tool steel and make a spacer so its one solid part, or weld the washers together so it acts as one.Originally posted by Mach 5 View PostI had this question so I called ARP and they said that it will act as a bearing. Ill have to call my machinist for the correct part # for better studs that are the right length that I used on my engine. I will let ya know. I just don't want to see you have another main failure

Leave a comment:

-

You should read the whole thread. The failure came from oil starvation due to RTV bits stuck in the dry sump.Originally posted by Mach 5 View PostI had this question so I called ARP and they said that it will act as a bearing. Ill have to call my machinist for the correct part # for better studs that are the right length that I used on my engine. I will let ya know. I just don't want to see you have another main failure

Leave a comment:

-

I had this question so I called ARP and they said that it will act as a bearing. Ill have to call my machinist for the correct part # for better studs that are the right length that I used on my engine. I will let ya know. I just don't want to see you have another main failure

Leave a comment:

-

I'm not to sure about this one. I like the runner length though. If there is a way you can do it a shape like a horn on the plenum end of the runner helps "signal strength" to the carbs(for the next intake). Also has a nice little ram effect.

Plenum total size seems to be close to stock. Your throttle changes alot and I'd think you are going to need more. Enough has been said on the middle runner problem, so I'll hold off on that. What happend to the cross ram idea?

Leave a comment:

-

Glad to see the project going again.

Curious to see exhaust gas temperature for the middle cylinder of each side.

Leave a comment:

-

The ARP main stud kit has too long bolts or too little thread in them.Originally posted by Mach 5 View Postlooks great!! cant wait for next video. one question Are you stacking washers on your main studs??

I had cut them shorter with a hacksaw .

But the machine shop seems to put now one extra washer , that you can see in the picture.

One thicker washer would be better than two, I suppose.

Leave a comment:

-

looks great!! cant wait for next video. one question Are you stacking washers on your main studs??

Leave a comment:

-

Just like Mr 1988GTU said: a boat anchor.

Thats what the "new" Lumina block was.

The camshaft was break and the cam bearings had spin in the bore.

The block was no good .

I took the crankshaft main bearing caps from that block and machine shop did a

main line honing to the old block.

The result was satisfying.

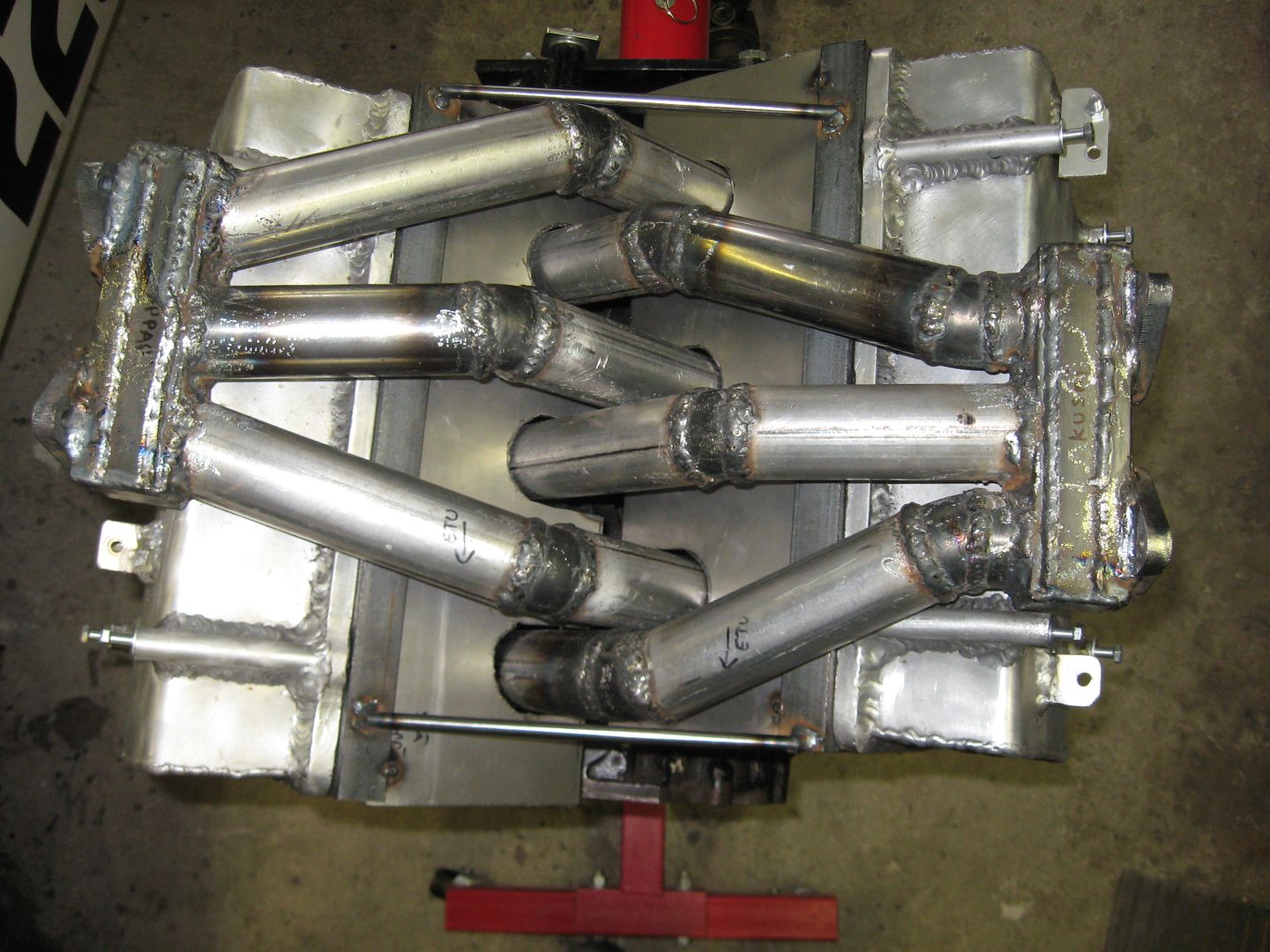

And some pictures how the new crossram intake looks today.

Leave a comment:

-

Guest repliedI came into possession of a similar engine, 3400, where the came split in the middle so cylinders 1,2 and 3 were still working. The block appeared fine, as in the came bearings didn't seem to spin in the bores. I was told that the engine lost power and shut off, though it would still run with no load.

Guest repliedI came into possession of a similar engine, 3400, where the came split in the middle so cylinders 1,2 and 3 were still working. The block appeared fine, as in the came bearings didn't seem to spin in the bores. I was told that the engine lost power and shut off, though it would still run with no load.

I ended up keeping only the pistons, and a few other parts from it, since I had a much cleaner block sitting in the corner, just missing some pistons and a couple other parts.

This block may be fine, if it went the same way the one I had did, that would stall when put into gear, unless you revved the shit out of it before dropping it in.

Leave a comment:

-

Those cam bearings are def going to neeed replacing. Hope they didn't spin in the bore.

Leave a comment:

-

When it quit is looks like it was running on cylinders 1,2 and 3 only, so I doubt he ran it long like that. Larry

Leave a comment:

-

Nice that GM designed high mileage displacement on demand for these motors...

Check that block over real good, might just be a boat anchor.

Leave a comment:

-

Yeah and with no oil pump running odds of the bearings spinning on the cam journals are very high... I wonder if this block is any good for him.

Leave a comment:

Leave a comment: