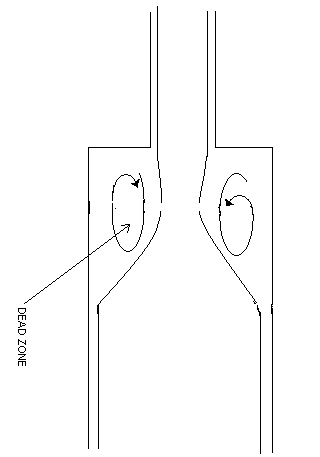

Not the best, but it's all I have. No I did not do it. The Eco guys were swapping larger intakes(using their smaller TB) and a flat adapter. Kept telling them they were hurting the flow. Showed them that and it didn't change anything. Just got to laugh I guess.

Very refreshing to hear someone speak of it after it fell on so many deaf ears.

Use to have a great video with the air/smoke in motion at different speeds on the same model. Talk about loss of throttle response.

Leave a comment: