I'll try to get some pics tomorrow when i get out of work.

With the first set of long tubes i built i made the mistake of getting the primaries too close to the top of the '282 bell housing, i ended up grinding a lot of material off of the trans bracket to get it to clear. no fun...

Announcement

Collapse

No announcement yet.

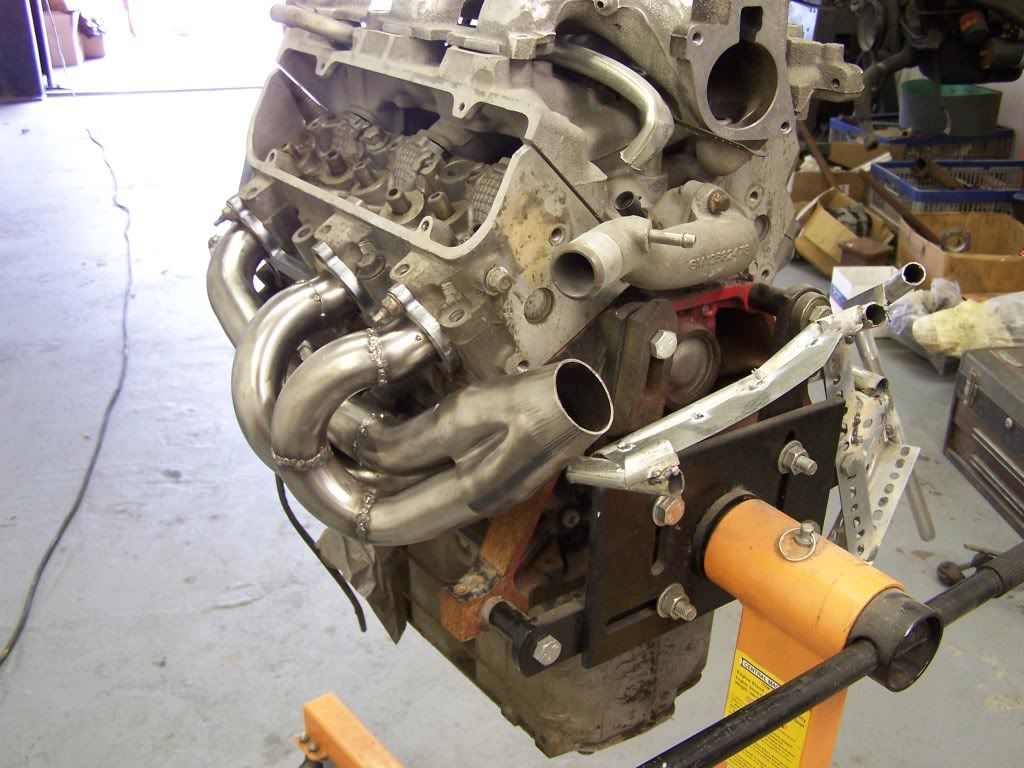

Project: L-body headers

Collapse

X

-

Pics are nice.

I started messing with the crossover after welding the primary seems up, but haven't welded anything. The crossover starting so close to the corner of the head makes the jig look HUGE in that area where the collector was on the S&S. Looking straight at the back of the block, you could have a bell housing that literally was straight out from the mounting bosses lol. I'll take pics of that area.

Well, they didn't end up perfectly equal length but they are really close

Issac, Loner's car had trouble with that hard line for his turbo kit (also the fan) so we cut it with some copper cutters, flared the end a little and used rubber to move it.

I noticed the oil pressure sensor, if it's the same location as the 3500, then you will want to either cover it with something, or put an elbow on it and make the sensor face a little down (45* is sufficient).

If you would rather, I can make your set obnoxiously non-equal length to clear everything :P

Leave a comment:

-

Yes Dave, please do!!!! please! Shift cables are not something I thought of. I'm sure John will tell you yes as well.

Leave a comment:

-

The crossover will tell the story...

Forced, if you want measurements with pictures just let me know... i have a HM282 sitting 12" from a spare block and my headers are up on a shelf.

One of the big concerns with a 5 speed is clearing the shift cables, i had to wrap my cables in a few layers of fiberglass heat wrap because they sat very close to the rear header.

Leave a comment:

-

Having the collector back further like this and just a smaller 2" cross over tube going should help with the older mount bracket... Clearing the bell housing is another issue though.

Leave a comment:

-

my big concern is are they going to fit over the tranny on 5 speed cars? a guy over on bstuff had to mod the shit outta his tranny and mount bracket to use S&S headers.....

Leave a comment:

-

I don't think he's used them yet. He bought them several years ago to put on his 3400 that was going in the blue 1st gen.Originally posted by torq455 View PostMajor has headers?! What kind of a gain did he get?

they were a stepped tube shorty design, i forget the primary length but the started off at 1 5/8 and stepped down to 1 1/2" after a few inches. 2" crossover and a 2.5" collector.

Leave a comment:

-

Once you get them finished you should send them out and them digitized. Then in the future you could have have pre made mandrel bent tubes that you would just weld to the collectors.

Leave a comment:

-

John, my only concern with you making these better is that you might stay within the dimenions of your jig, but might run into other areas that are not on your motor. Items that you really need to put on that engine to check:

Starter (old ones are large)

Oil pressure sender (the long variable ones)

Dipstick

Coolant return line that goes into the Timing cover/water pump housing.

That last one is a big concern right now, I'm thinking the new routing is going to run into it.

Here is a picture for an idea:

Here are more shots with SS installed:

http://i257.photobucket.com/albums/h...d/100_2206.jpg

http://i257.photobucket.com/albums/hh201/3400modified/100_2205-1.jpg

I just don't want you to have to re-do them multiple times. But the new design does look pimp!Last edited by IsaacHayes; 12-05-2009, 04:05 PM.

Leave a comment:

-

I only did the rear bank and cross over angle modification to his and Eric Wood's, I did not do the collector shortening and re-angle because I did not have it in the tunnel of a car to verify the fit. I told BOTH of them this and STRONGLY suggested having an exhaust shop cut that back and re-angle it to correct it. I even provide the necessary pics.

Neither person did this and that is why Woody's header's have a really akward bend in them after the collector, AND why Eric B can't fit his swaybar in there. It's not that it won't work, its that they never completed what I could not do since I only modified them on a block.

Mine were done as I noted and I'm running a 30mm GT swaybar with NO issues.

And John, I know you did loner's but those were turbo headers, that don't count... LOL

If I was closer to ANYONE on this board who has the capabilities to copy/reproduce the headers I would be all over dropping my car off for test fitting since I have a daily driver. But since I'm way the hell up here and almost as east as you can get... I'm helpless to this, other than being able to provide the first set of modifications that had to be done to get them to fit, granted yes I had to buy a $500 set of headers and cut and re-welded them myself... At the time I didn't have the time/tools to make a fully custom set.

I agree 100% with this, but at the time and still to this day till you finish this set, we did not have that option... our only option was a custom fab set from local shops where no one wanted to touch them, OR build your own, and as noted many don't have the tools to do so.Originally posted by ForcedFirebird View PostYou see, I just can't grasp the idea that you guys are paying for a set of headers, then paying to have them modified (if the user doesn't have the ability/tools) when you can just buy bolt-on's from the beginning.

The biggest issue is, the people willing to put up the money and time are NEVER located next to the guy who has the resources and desire to build what that person wants... and the only local people end up being no help.Last edited by 3400-95-Modified; 11-09-2009, 02:25 PM.

Leave a comment:

Leave a comment: