Originally posted by pocket-rocket

View Post

Announcement

Collapse

No announcement yet.

Project: L-body headers

Collapse

X

-

Grand Am coming soon. The j-bodies were lacking and didn't take advantage of the three beta sets, so once the 2 of those are finished we will be moving on to other body styles

Leave a comment:

-

They look great, and I am sure they will look even better coated.

I can't wait for you to start on headers for the Grand Am.

Leave a comment:

-

Well I guess function over form?

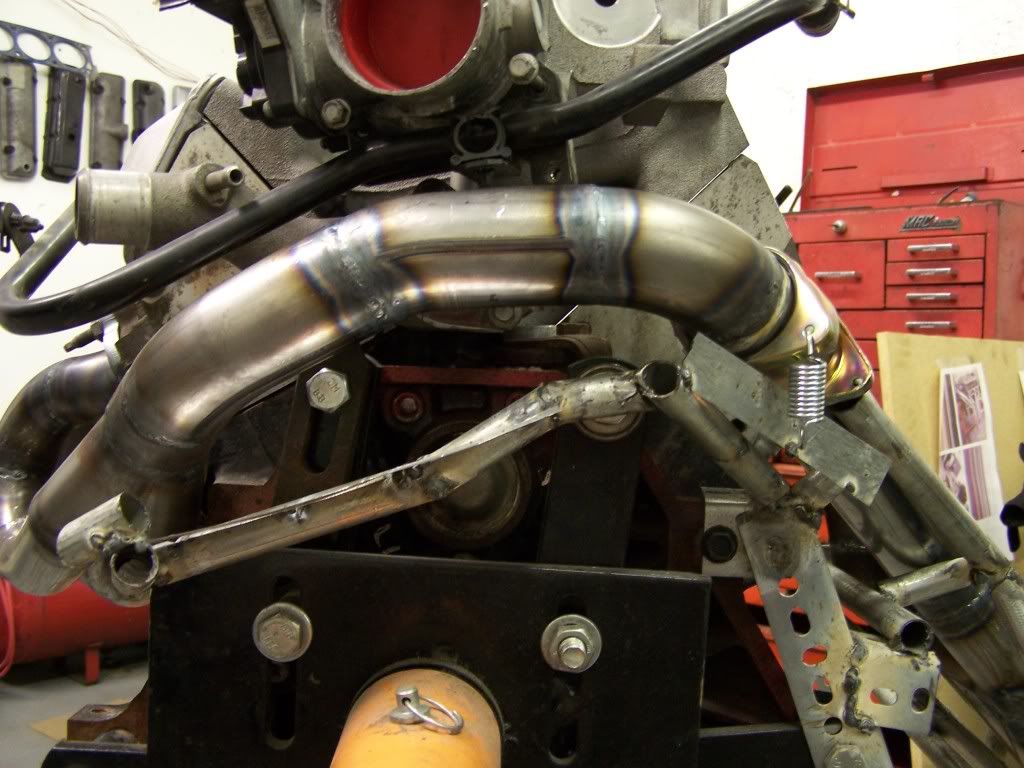

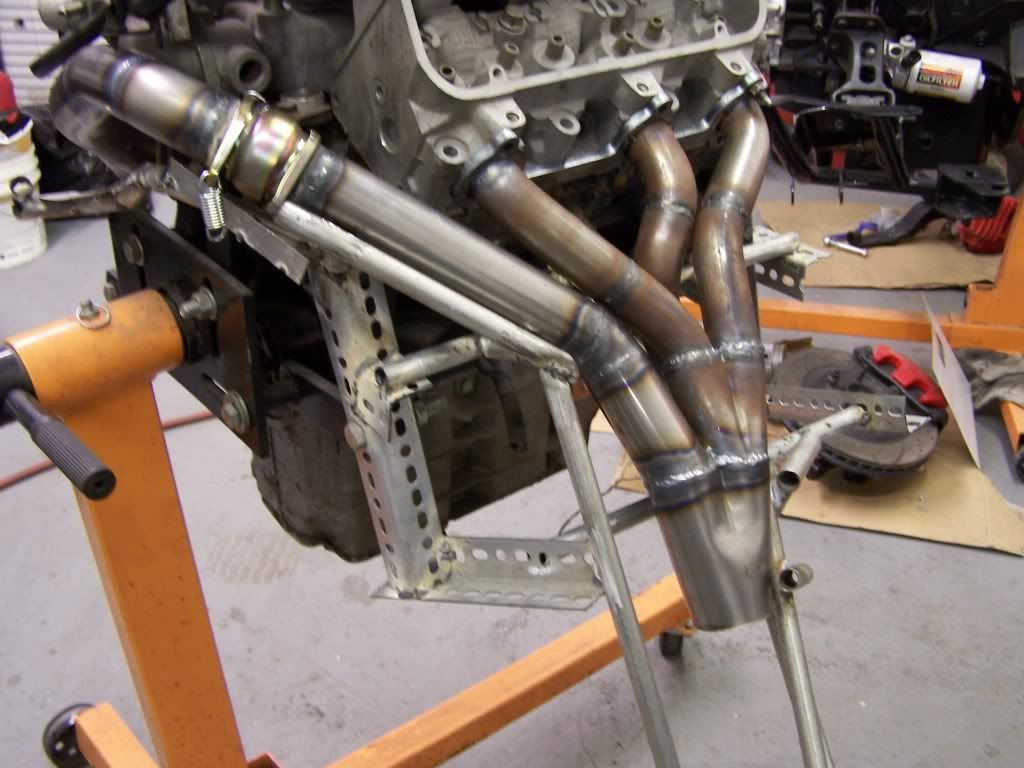

Have to weld a bend at the end of the 2-1 collectors, one EGR bung and two 02 sensor bungs, then they will be blasted, coated and they are OUT OF HERE!!!

Hope they will pass yall's approval

Leave a comment:

-

I am at a loss for words there... Does it even play nice with atmosphere?

Leave a comment:

-

Haa... i do it in one pass! Just need the right kind of weld! "N-RIG" weldingOriginally posted by ForcedFirebird View PostThere is no way to make most of the welds with 2 passes. Often the primary will have to be flipped over even in the process and the welds are actually going away from each other.

I wish there was a way to get a single pass, but with the remote, it's not like the MIG that I could walk around with the pipe vertical.

Some of my work! notice no seams!

Last edited by RedZMonte; 01-20-2010, 10:12 PM.

Last edited by RedZMonte; 01-20-2010, 10:12 PM.

Leave a comment:

-

MIG welding for 3 yrs and did brazing copper with 6% silver for 2, I know that part, but what about when you have to fill a gap larger than your filler from thick to thin material? I haven't found an efficient way to do so. If the heat is enough to pool the 3/8's, the radiant heat will often melt the external part of the pipe and make the gap to fill even largerOriginally posted by slinky View Postyeah you got to focus the arc toward the thicker plate and let it roll onto the thinner one

Leave a comment:

-

yeah you got to focus the arc toward the thicker plate and let it roll onto the thinner one

Leave a comment:

Leave a comment: